Biomass resource compost pressed film sealing system and a circulation sealing method

A biomass resource and sealing system technology, which is applied in the composting film sealing system and cycle sealing field of biomass resources, can solve the problems of high labor intensity and low operation efficiency, reduce labor intensity, improve operation efficiency, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

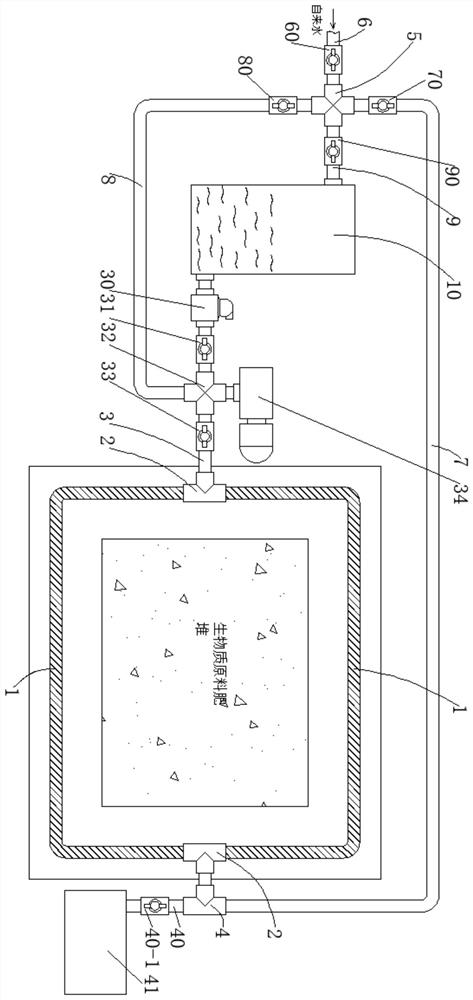

[0052]A cyclic sealing method of a compost pressure film sealing system for biomass resources, specifically comprising the following steps,

[0053] Step S1: open valve 4 60 and valve 7 90, close valve 5 70, valve 6 80 and valve 3 40-1, and tap water enters the water tank 10 through the water inlet pipe 6, four-way one 5 and water pipe four 9 until it is full water tank 10;

[0054] Step S2: close valve four 60, open valve five 70, valve one 31 and valve two 33;

[0055] Step S3: start the water pump 30, and the water pump 30 will pass the water in the water tank 10 through the valve one 31, four-way two 32, valve two 33 and one side three-way one 2 into the water pipe bags 1 on both sides, and then through the other side three Pass 1 2, tee 2 4, water pipe 2 7, four pipe 1 5, water pipe 4 9 return to the water tank 10 until the water pipe 4 9 at the upper end of the water tank 10 enters the water tank 10 evenly, and then close valve 1 31 and valve 2 33 in turn , valve five ...

Embodiment 2

[0062] In the composting film sealing system for biomass resources, the water stored in the water tank 10 can be recycled under the action of the water pump 30 and the pressurized air pump 34, which avoids the waste of water resources and saves energy and reduces emissions.

[0063] Failures such as power outages, you can open valve four 60, valve six 80, valve two 33 and valve three 40-1, close valve five 70, valve seven 90 and valve one 31, so that tap water flows from water inlet pipe 6, four-way one 5, water pipe Three 8, four-way two 32, valve two 33, one side three-way one 2 enter the water pipe bag 1, and then pass through three-way one 2, three-way two 4, valve three 40-1 and discharge into the seepage well 41 until the drain pipe The water output of 40 is uniform, and valve two 33 and valve three 40-1 are closed, realizing timely remedial measures.

[0064] Both water and tap water in the water tank can be discharged in the seepage well 41.

[0065] The water tube ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com