Functional fiber, preparation method and wearable device

A functional fiber and fiber technology, applied in fiber treatment, bracelets, watch straps, etc., can solve the problems of skin prone to eczema, large price differences, airtight gloss, etc., to reduce the probability of eczema, and the structural luster is durable , enhance the effect of gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of the above-mentioned functional fibers, comprising

[0045] Processing the raw material into a fiber body 1 with a rounded triangle cross section and an inner cavity 3;

[0046] Heat the fiber body 1 to 60-65°C, and at the same time fill the inner cavity 3 with a transparent fluid containing reflective sheets;

[0047] After filling, the inner cavity 3 is sealed;

[0048] Polishing the surface of the sealed fiber body 1 and cooling it to 36-37°C;

[0049] The functional fiber is obtained by performing hydrophobic treatment on the surface of the polished fiber body 1 .

[0050]It can be seen from the above description that by heating the fiber body 1 to 60-65°C and filling the inner cavity 3 with fluid containing reflective sheets, since the temperature of the human body generally does not exceed 40°C, the limit that the human body can bear does not exceed 60°C. Therefore, the temperature is the same as that of the highest use environment, and t...

Embodiment 1

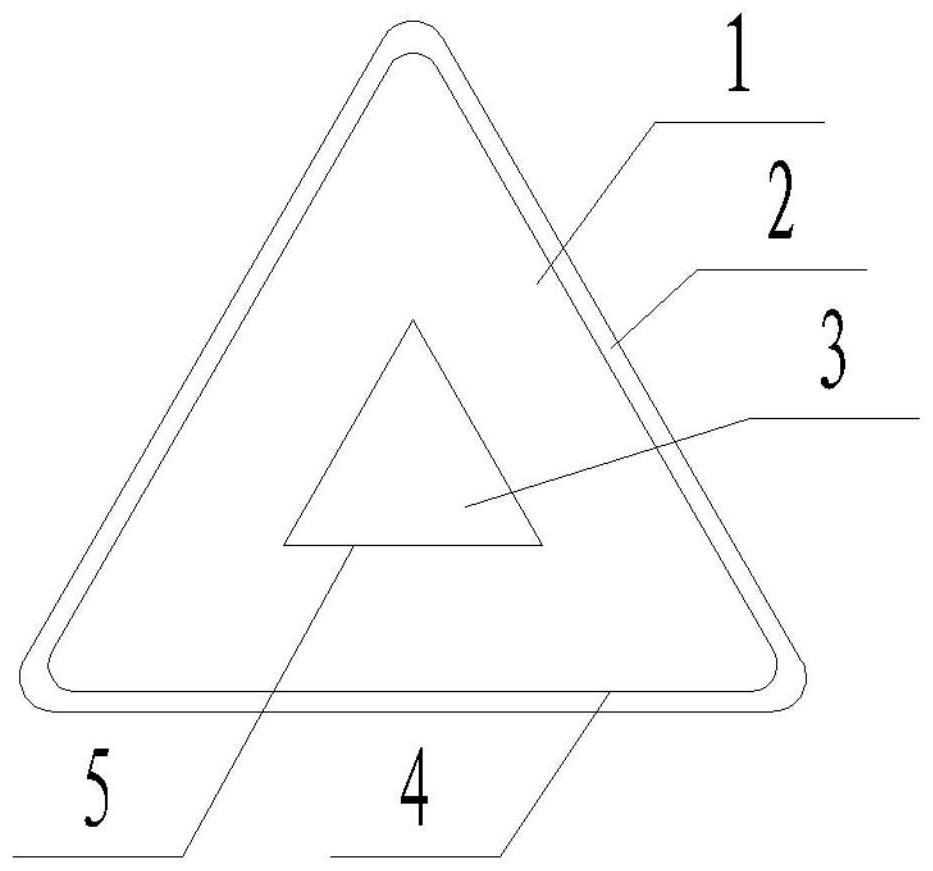

[0058] Please refer to figure 1 , a functional fiber, comprising a transparent fiber body, the cross-section of the fiber body is a rounded triangle;

[0059] The outer surface of the fiber body is polished, and a transparent water-repellent layer is arranged on the outer surface of the fiber body;

[0060] The fiber body is provided with an inner cavity opened along the length direction, and the axis of the inner cavity coincides with the inscribed circle of the fiber body; there is a transparent fluid in the inner cavity, and multiple fluids are mixed in the fluid. reflective sheeting.

[0061] The section of the inner cavity is a regular triangle.

[0062] The reflective sheet has the same charge, the inner wall of the cavity has a transparent insulating coating, and the fluid is an insulating liquid.

[0063] The fluid is pure water.

[0064] The material of the fiber body is transparent nylon.

Embodiment 2

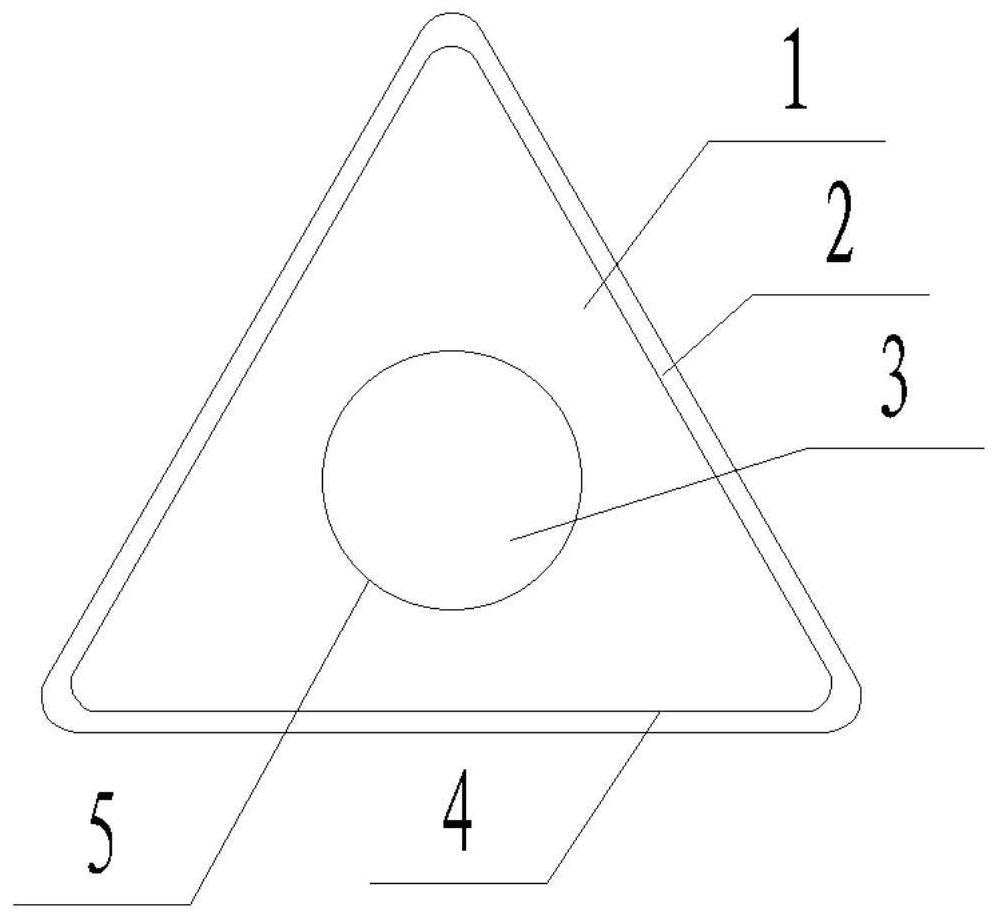

[0066] Please refer to figure 2 , a functional fiber, comprising a transparent fiber body, the cross-section of the fiber body is a rounded triangle;

[0067] The outer surface of the fiber body is polished, and a transparent water-repellent layer is arranged on the outer surface of the fiber body;

[0068] The fiber body is provided with an inner cavity opened along the length direction, and the axis of the inner cavity coincides with the inscribed circle of the fiber body; there is a transparent fluid in the inner cavity, and multiple fluids are mixed in the fluid. reflective sheeting.

[0069] The cross section of the cavity is circular.

[0070] The reflective sheet has the same charge, the inner wall of the cavity has a transparent insulating coating, and the fluid is an insulating liquid.

[0071] The fluid is distilled water.

[0072] The material of the fiber body is transparent PVC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com