Gravel fine particle material methylene blue rapid screening detection method

A technology of methylene blue and detection method, which is applied in the direction of chemical analysis by titration method, which can solve the problems of time-consuming and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described more specifically by referring to the following embodiments.

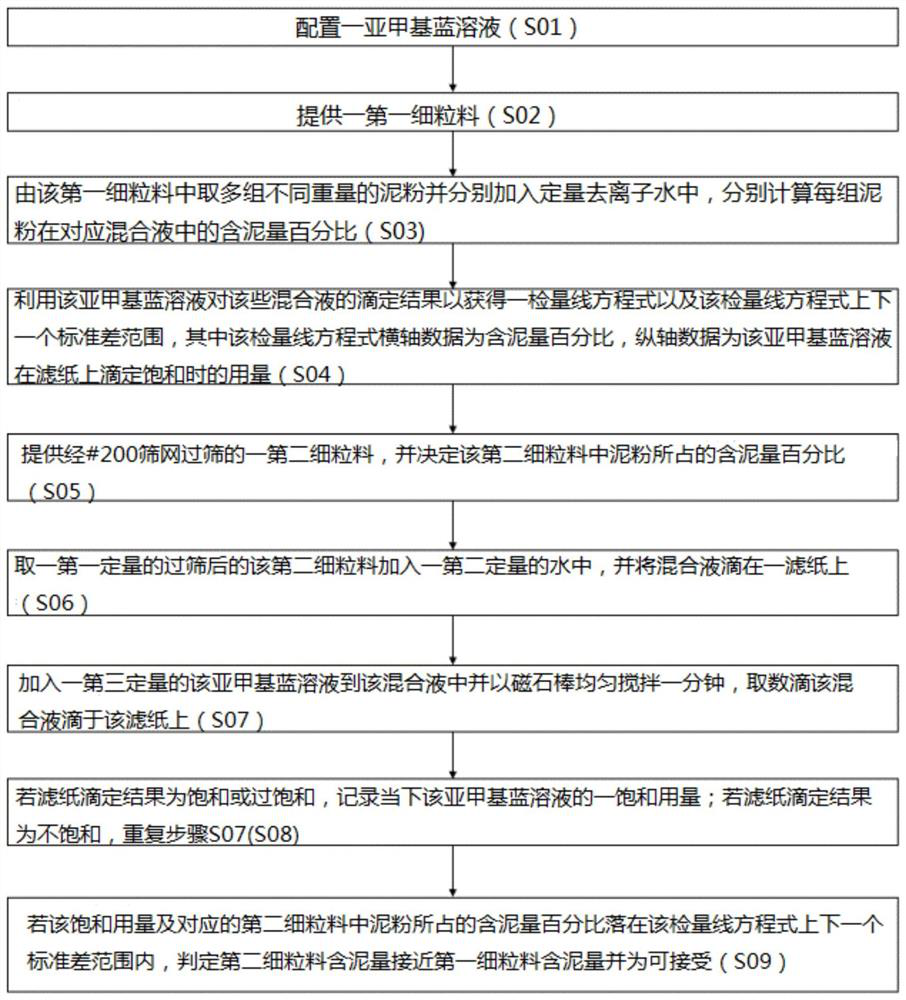

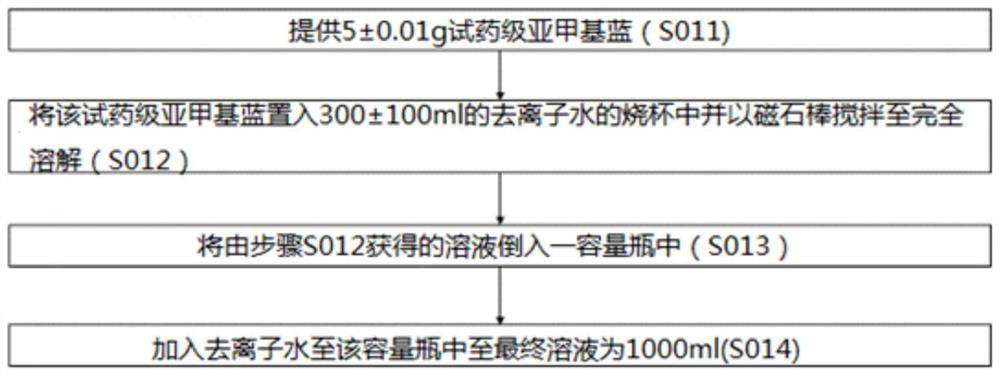

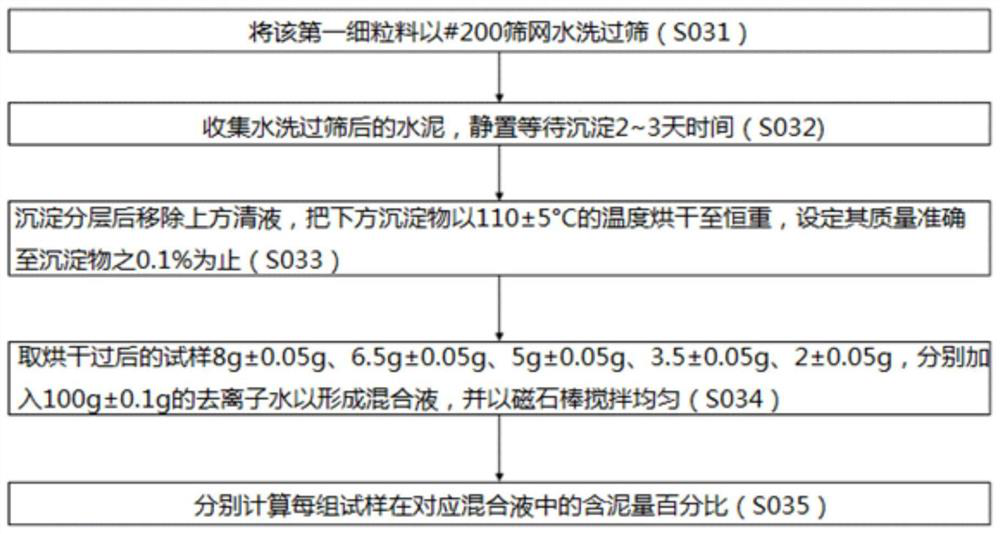

[0028] please see figure 1, which is a flow chart of a quick screening method for methylene blue sand and gravel particles according to an embodiment of the present invention. According to the spirit of the present invention, the first step of the rapid screening method is to prepare a methylene blue solution (S01) for testing. For the configuration of methylene blue solution, please refer to figure 2 , which is a flow chart of methylene blue solution configuration.

[0029] First, provide 5±0.01 g of reagent grade methylene blue (S011). Next, put the reagent-grade methylene blue into a beaker of 300±100ml deionized water and stir it with a magnet bar until it is completely dissolved (S012). Afterwards, pour the solution obtained in step S012 into a volumetric flask (S013). It is best to use deionization to rinse the residual liquid on the beaker into the volumetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com