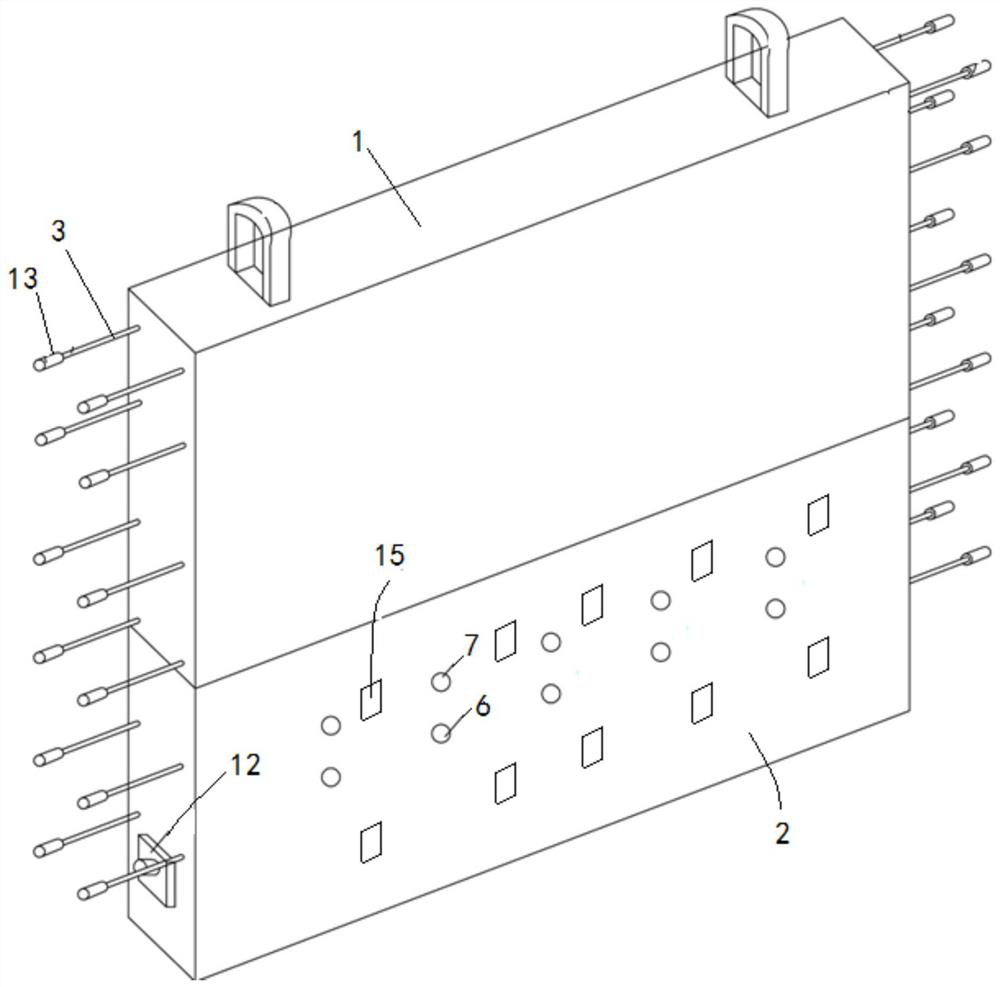

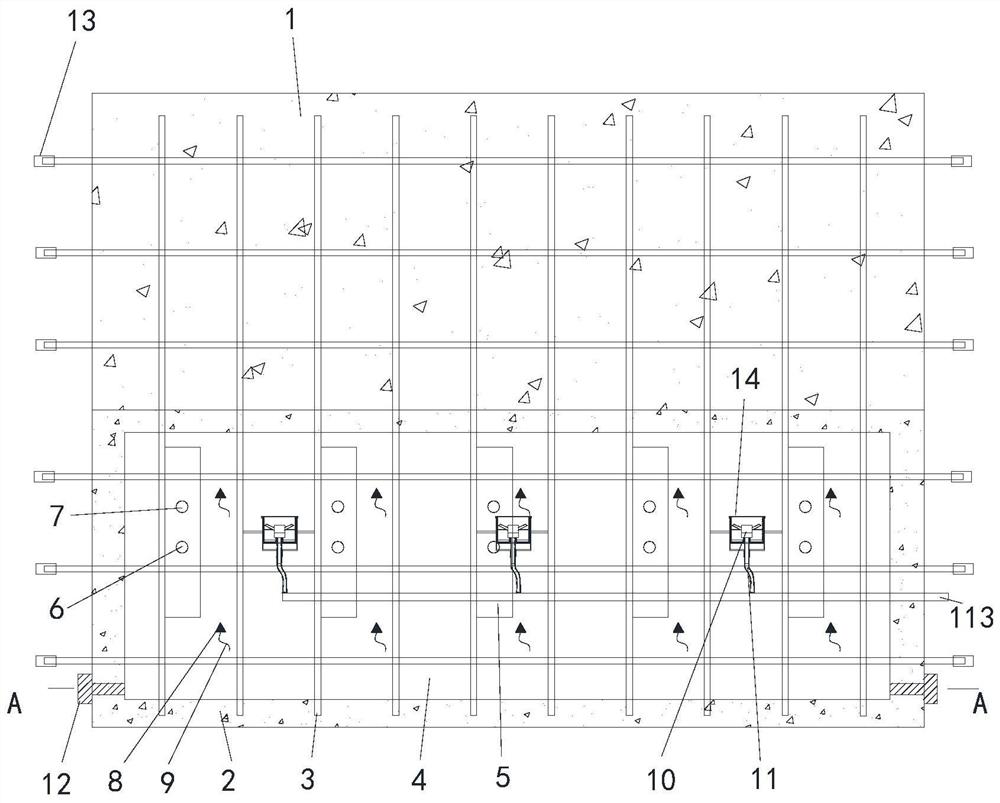

Fabricated building grouting teaching and practical training device

A training device and an assembled technology, which are applied in teaching models, simulation devices for astronautical conditions, educational appliances, etc., can solve the problems of inability to meet the requirements of repeated operations in grouting teaching training, inability to clean, and bulky prefabricated components. , to achieve the effect of reducing maintenance frequency, not easy to fall, and less harmful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

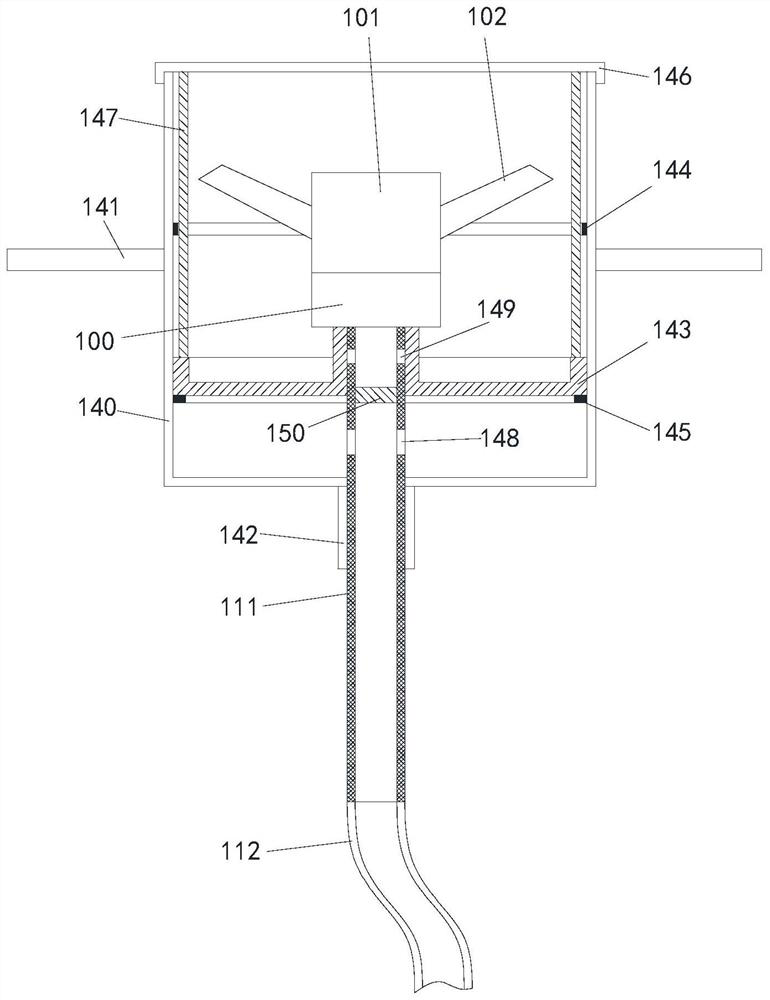

[0027]Comparative Example 2. Compared with the embodiment, the anti-clogging device 14 does not have a water blocking block 150, a first water outlet 148, and a second water outlet 149.

[0028]Taking 10 training sessions per day and 20 days of training each month as an example, the rotary nozzle 10 of Comparative Example 1 needs to be maintained after the 10 training sessions per day, that is, the rotary nozzle 10 is flushed to prevent the rotary nozzle 10 is solidified by the residual grouting liquid and cannot rotate. In Comparative Example 2, although the rotating nozzle 10 basically does not become clogged, it needs to be maintained after 10 training sessions per day. The anti-clogging device 14 is flushed to avoid residual grout remaining in the anti-clogging device. On 14, the grouting liquid solidifies on the anti-clogging device 14 to form a condensate sheet, which connects the hard tube 111 and the guide sleeve 142, the cover plate 146 and the cylinder 140, and the tap water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com