Automatic playing device applied to plucked stringed musical instrument

A technology for automatic playing and plucked stringed instruments, which is applied to electro-acoustic musical instruments, instruments, harps, etc. It can solve the problems of complex structure, slow response speed of plucked strings, difficult installation and positioning of brackets, etc., and achieve simple and direct control, fast response speed, Swing control direct and swift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

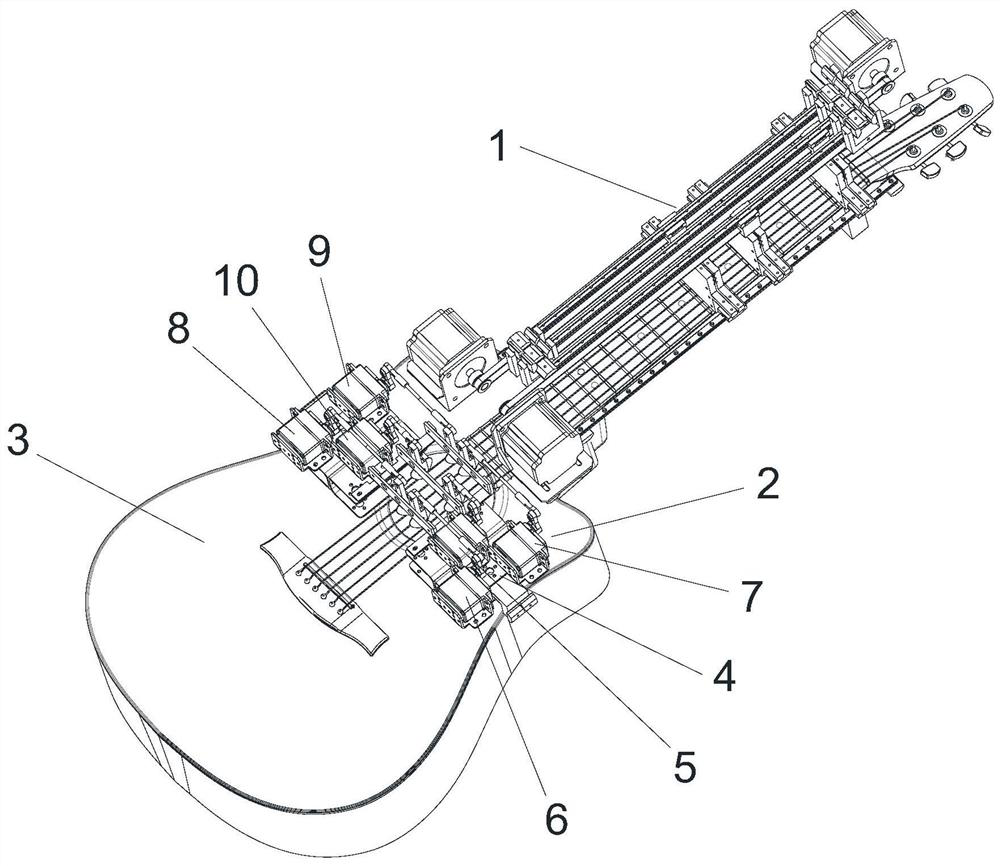

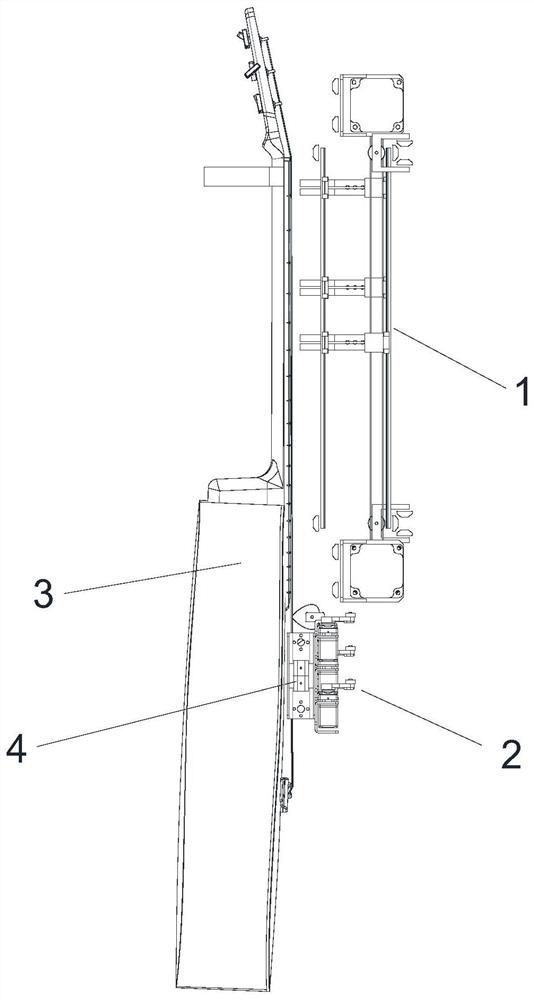

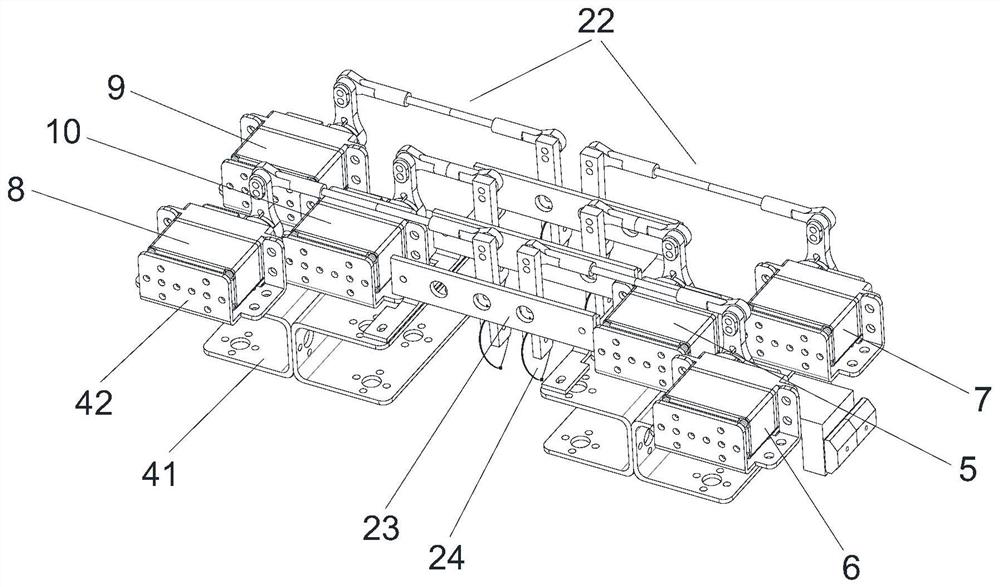

[0033] Please refer to Figure 1 to Figure 13As shown, the embodiment of the present invention discloses an automatic playing device applied to a plucked string instrument, including a base 4 relatively fixed to the instrument body 3, a control system and a string pressing mechanism 1 and a pizzicato controlled by the control system. A string mechanism 2, the string picking mechanism 2 is arranged on the base 4, the string picking mechanism 2 also includes a plurality of string picking assemblies controlled by the control system, and each string picking assembly is arranged laterally on the musical instrument At the sound cavity of the body 3, each of the pizzicato components 2 includes a steering gear 21 arranged on the base 4, a connecting arm 22 driven by the steering gear 21, and a stopper fixed relatively to the instrument body 3 23 and the paddle 24 located at the end of the connecting arm 22, the connecting arm 22 includes a front connecting rod 221, a rear connecting r...

no. 2 example

[0056] As an improvement to the above-mentioned first embodiment, in this embodiment, a first lifting mechanism is also provided between the "I"-shaped fixing bracket and the steering gear mounting base, and the "日"-shaped limit Each horizontal support of the positioner is provided with a second lifting mechanism on both sides of the vertical support. The first lifting mechanism is used to raise or lower the height of the steering gear, and the second lifting mechanism is used to lift or lower one of the horizontal supports. Side or Side Height to change the height of the paddles. Exemplarily, when the control system controls the first lifting mechanism below the steering gear mounting seat of any pizzicato assembly to rise, at the same time controls the second elevating mechanism on the side of the transverse bracket corresponding to the pizzicato assembly to rise, so as to lift the corresponding The height of the plectrum of the plucked string assembly reduces the contact ar...

no. 3 example

[0058] As another improvement to the above-mentioned first embodiment, in this embodiment, the hinge position includes a limit chute, the limit block is a sliding shaft, and the middle part of the swing arm is connected to the On the limiting chute, when the swing arm is driven by the rear link to swing, the sliding shaft reciprocates along the limiting chute with a second track to change the swing fulcrum position of the swing arm .

[0059] As a preferred solution, the shape of the above-mentioned limiting chute and the second trajectory is an arc or a closed loop, and the first trajectory includes an upper closed section and a lower closed section connected to each other, and the lower closed section corresponds to the The strings intersect perpendicularly.

[0060] In this embodiment, a limit chute is provided at the hinged position, and a sliding shaft is used as a limit block, so that when the swing arm is driven by the steering gear to swing, the limit block slides in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com