Shielding ball

A technology of shielding balls and spheres, applied in electrical components, insulators, circuits, etc., can solve the problem of corona-prone shielding balls, and achieve the effect of enhancing the supercharged shielding effect, not easy to corona, and small field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

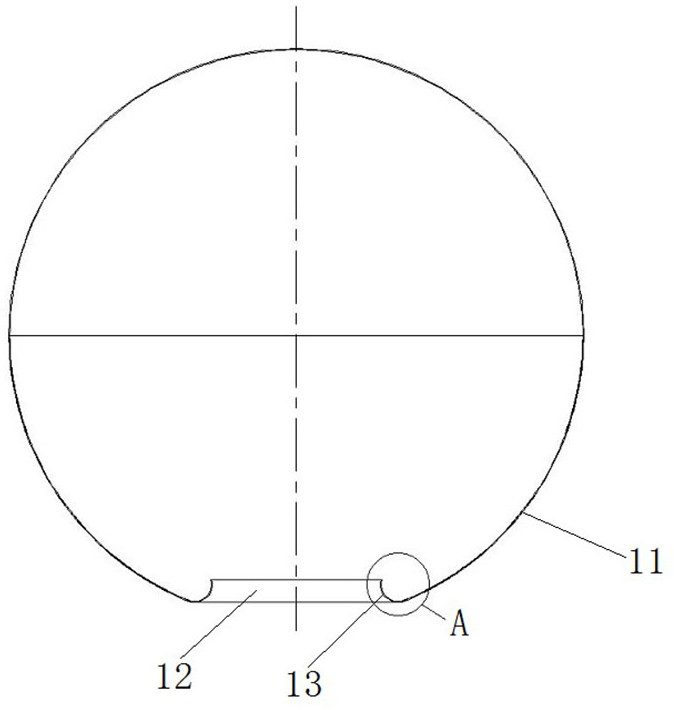

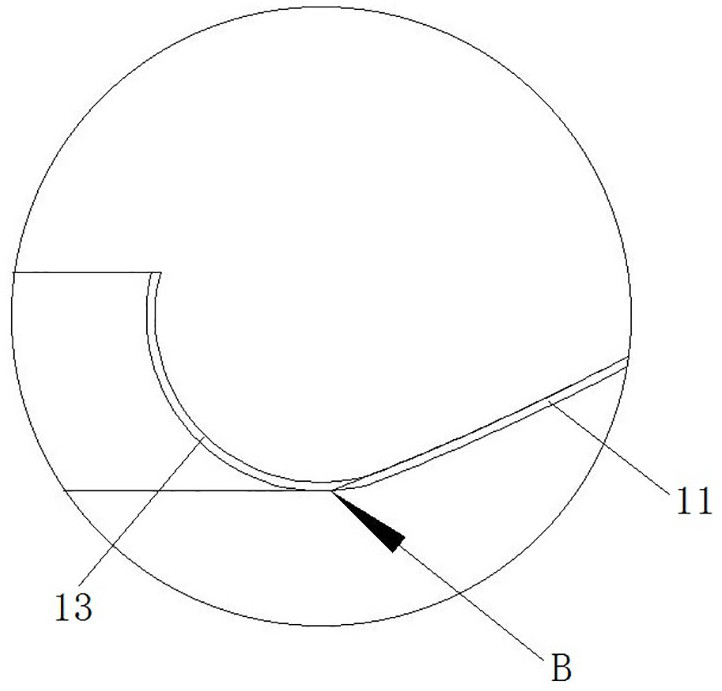

specific Embodiment 1

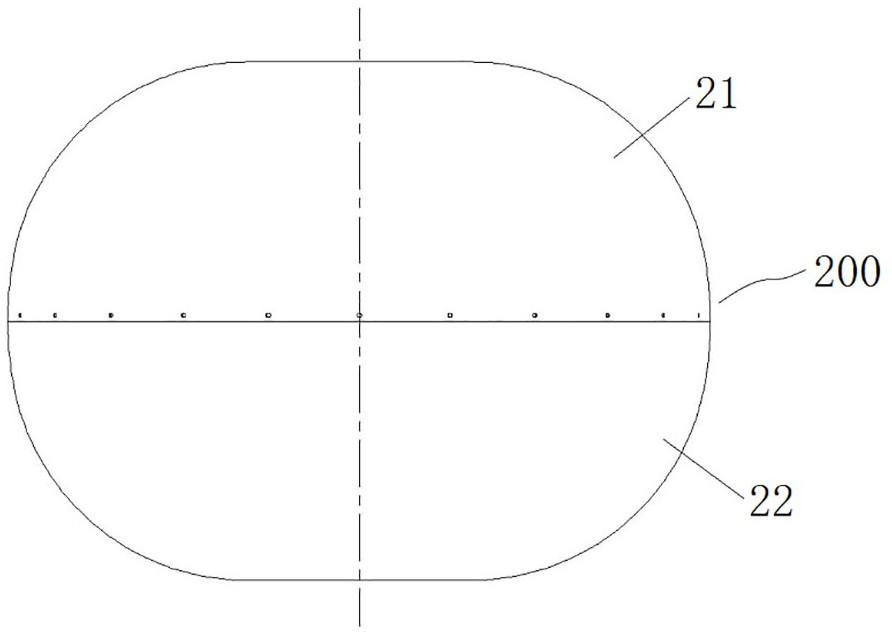

[0033] Such as Figure 3 to Figure 6 As shown, the shielding ball includes a sphere 200, and two perforations 23 ( Figure 4 Only the perforation 23 at the lower end is shown in the figure), arc-shaped flanges 24 are provided at the edges of the two perforations 23 to even out the electric field, and the sphere 200 and the arc-shaped flanges 24 are smoothly connected.

[0034] Such as Figure 4 As shown, the sphere 200 includes an upper hemisphere 21 and a lower hemisphere 22. The upper and lower hemispheres are combined to form a sphere 200. A connecting ring 25 is welded inside the lower hemisphere 22. The connecting ring 25 is welded against the inner wall of the lower hemisphere 22. A plurality of threaded holes are evenly distributed along the circumferential direction on the upper surface. After welding, each threaded hole is located on the horizontal plane where the center of the lower hemisphere is located. Countersunk holes are evenly distributed on the outer periph...

Embodiment 1

[0043] In Embodiment 1, a connecting ring is fixed on the lower hemisphere, and a counterbore is provided on the upper hemisphere. In this embodiment, the connecting ring is fixed on the upper hemisphere, and a counterbore is provided on the lower hemisphere.

specific Embodiment 3

[0045] In Embodiment 1, the upper and lower hemispheres are detachably connected by screws. In this embodiment, after the upper and lower hemispheres are respectively processed, they are fixedly connected together by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com