A metal-air battery based on fe(ii)/fe(iii) chemical oxidation and electrochemical reduction

A metal-air battery and chemical oxidation technology, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, can solve problems such as loss of activity, pollute the environment, and complicate preparation, and achieve the effect of increasing the discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

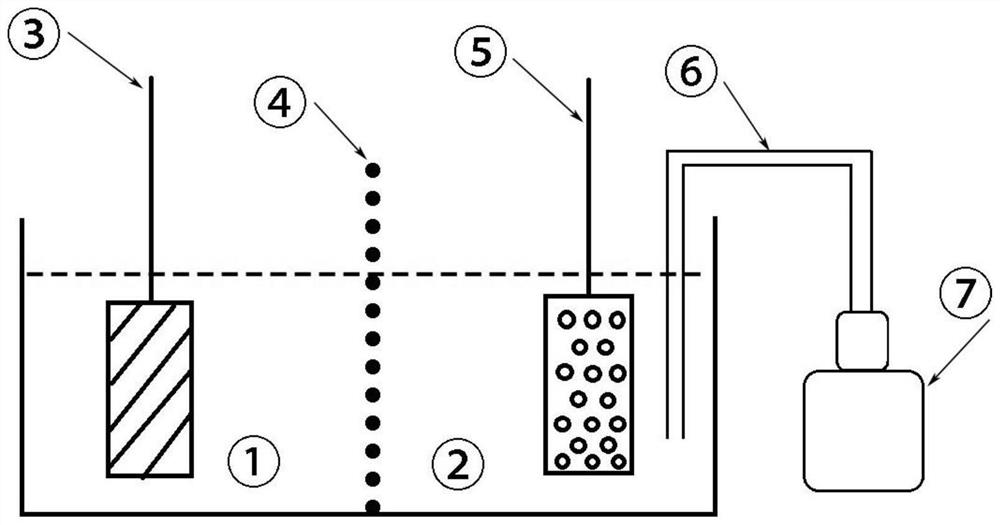

[0043] Immerse the industrial pure aluminum metal plate in the degassed saturated sodium chloride solution to obtain the negative electrode of the battery;

[0044] Immerse the graphite felt electrode in 0.5mol / L acid ferric nitrate solution to obtain the positive electrode of the battery;

[0045] The negative electrode electrolyte and the positive electrode electrolyte are separated by an anion semi-permeable membrane;

[0046] One end of the vent tube is immersed in the positive electrolyte, and the other end is connected to an air pump to form a metal-air battery based on Fe(II) / Fe(III) chemical oxidation and electrochemical reduction.

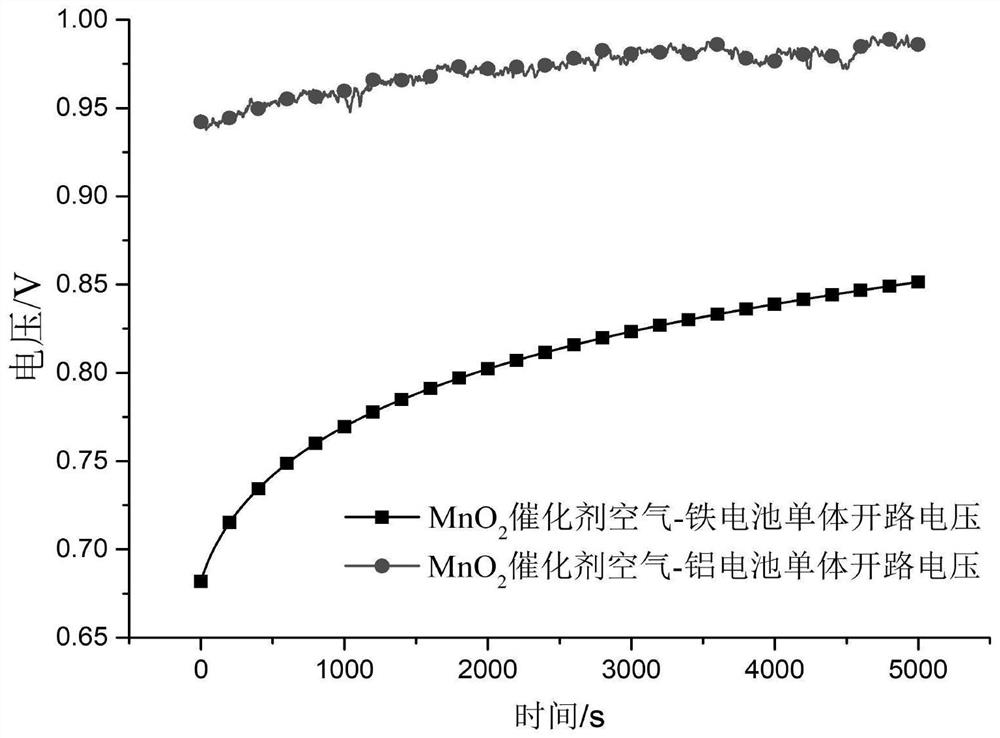

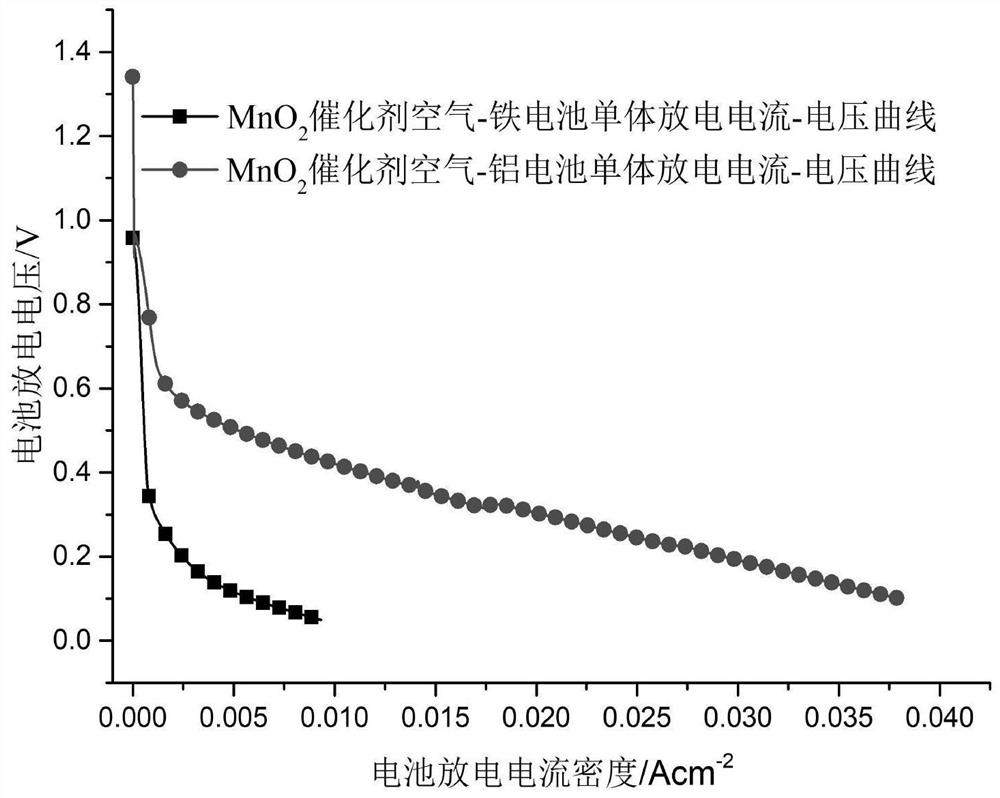

[0047] Test the discharge performance of the battery, the open circuit voltage is 1.33V, and the maximum discharge current density is 70mA×cm -2 .

Embodiment 2

[0049] Immerse the industrial pure aluminum metal plate in the degassed 3mol / L sodium chloride solution to obtain the negative electrode of the battery;

[0050] Immerse the graphite felt electrode in 1mol / L acid ferric sulfate solution to obtain the positive electrode of the battery;

[0051] The negative electrode electrolyte and the positive electrode electrolyte are separated by an anion semi-permeable membrane;

[0052] One end of the vent tube is immersed in the positive electrolyte, and the other end is connected to an air pump to form a metal-air battery based on Fe(II) / Fe(III) chemical oxidation and electrochemical reduction.

[0053] Test the discharge performance of the battery, the open circuit voltage is 1.41V, and the maximum discharge current density is 80mA×cm -2 .

Embodiment 3

[0055] Immerse the industrial pure aluminum metal plate in the degassed 2mol / L sodium chloride solution to obtain the negative electrode of the battery;

[0056] Immerse the graphite felt electrode in 2mol / L acid ferric chloride solution to obtain the positive electrode of the battery;

[0057] The negative electrode electrolyte and the positive electrode electrolyte are separated by an anion semi-permeable membrane;

[0058] One end of the vent tube is immersed in the positive electrolyte, and the other end is connected to an air pump to form a metal-air battery based on Fe(II) / Fe(III) chemical oxidation and electrochemical reduction.

[0059] Test the discharge performance of the battery, the open circuit voltage is 1.41V, and the maximum discharge current density is 80mA×cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com