Cellular glass product and process for making the same

A honeycomb and glass technology, applied in the fields of honeycomb glass products and manufacturing honeycomb glass products, can solve problems such as the decrease of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

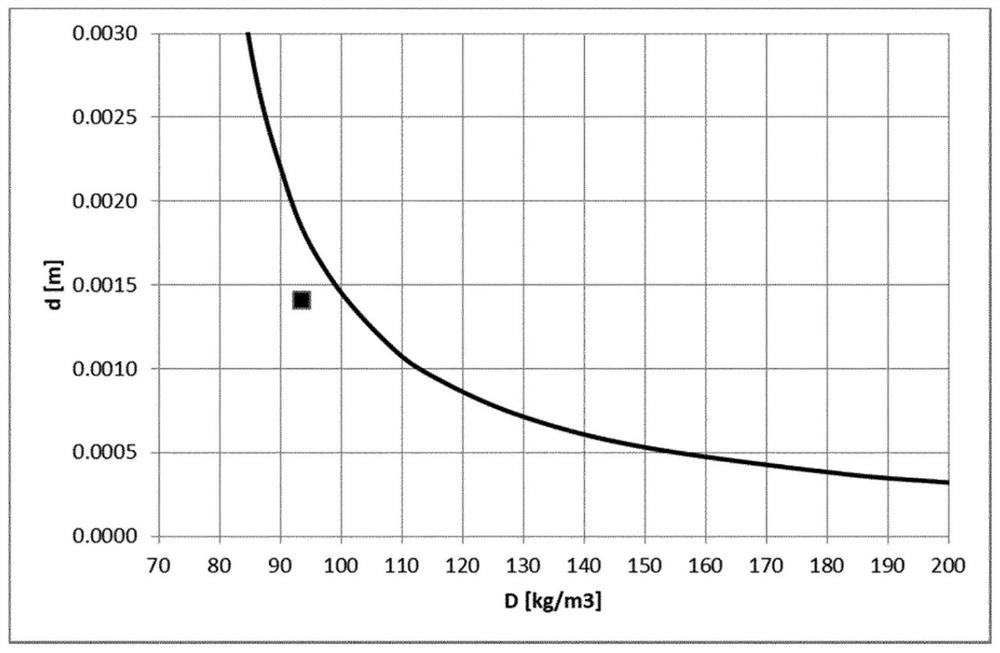

[0247] The silicate glass powder is mixed with carbon black to form a mixture of silicate glass and carbon black powder. Silicate glass powder has 2515kg / m 3 The bulk density, and to produce 94kg / m 3 The desired quantity of the density of the honeycomb glass product is provided.

[0248] Carbon black powder to provide production with 94kg / m 3 Provided in an amount of density at least 150% of the theoretical minimum amount of carbon required for the cellular glass. Silicate glass powder contains SO 4 2- form of sufficient free oxygen to also provide a 3 Free oxygen is provided in an amount of density at least 150% of the theoretical minimum oxygen amount of the honeycomb glass.

[0249] The dry mixture of silicate glass and carbon black powder was processed in a foaming furnace at a maximum foaming temperature of about 800°C to form a honeycomb glass. The glass honeycomb is further annealed in the lehr by cooling the glass honeycomb. Gained honeycomb glass has about 94k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com