A multi-nozzle glaze spraying robot

A multi-nozzle and robot technology, applied in the field of robotics, can solve the problems of reducing the diameter of the spray gun, harm, and reducing the mist output of the glaze, so as to ensure the mist output and speed up the flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] as attached figure 1 to attach Figure 5 Shown:

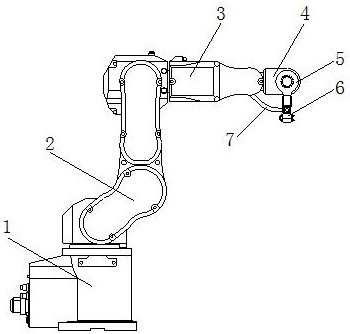

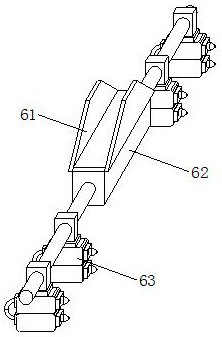

[0027] The present invention is a kind of multi-nozzle spraying glaze robot, and its structure comprises supporting base 1, rotating arm 2, supporting arm 3, rotating shaft 4, supporting plate 5, spraying glaze mechanism 6, spraying glaze conduit 7, described supporting base 1 top and The lower end of the rotating arm 2 is axially connected, the upper end of the rotating arm 2 is axially connected with the left end of the supporting arm 3, the front end of the supporting arm 3 is provided with a rotating shaft 4, and the rotating shaft 4 is axially connected with the upper end of the supporting plate 5, and the supporting plate 5 The lower end is welded to the upper end of the glaze spraying mechanism 6, and the right end of the glaze spraying conduit 7 is embedded and installed with the glaze spraying mechanism 6. The glaze spraying mechanism 6 includes a connecting frame 61, a glaze storage box 62, and a multi-nozzle ...

Embodiment 2

[0034] as attached Figure 6 to attach Figure 9 Shown:

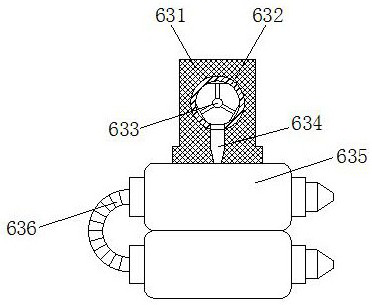

[0035] Wherein, the anti-blocking nozzle 635 includes a spray chamber 35a, a swing mechanism 35b, a left outlet groove 35c, a right outlet groove 35d, and a nozzle 35e. The lower end is provided with a swing mechanism 35b, the inner left end of the spray chamber 35a is provided with a left outlet groove 35c, and the inner right end of the spray chamber 35a is provided with a right outlet groove 35d, and the outside of the right end of the spray chamber 35a is fixedly equipped with a nozzle 35e. A spring is also provided at the lower end of the mechanism 35b, and the elastic force of the spring makes the swing mechanism 35b swing left and right to speed up the flow speed of the glaze slurry, and less glaze slurry stays inside the spray chamber 35a.

[0036] Wherein, the swing mechanism 35b includes a swing plate b1, a leak-proof plate b2, a hinge shaft b3, a left runner b4, and a right runner b5. The inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com