Irradiation crosslinking flame-retardant polyolefin foaming material internal mixing equipment

A polyolefin foaming and banburying technology, which is applied in the field of irradiation cross-linked flame-retardant polyolefin foam material banburying equipment, can solve the problems of not achieving uniform banburying, staff burns, and lack of cooling, etc., to achieve Improve the mixing rate, increase production strength, and increase the effect of fusion density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

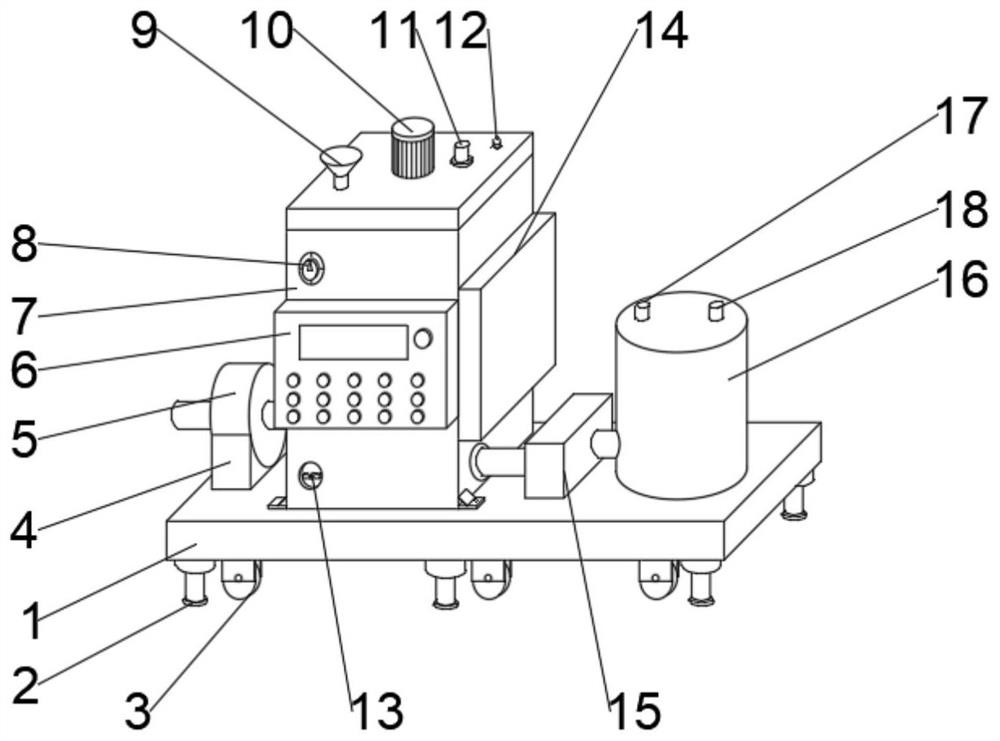

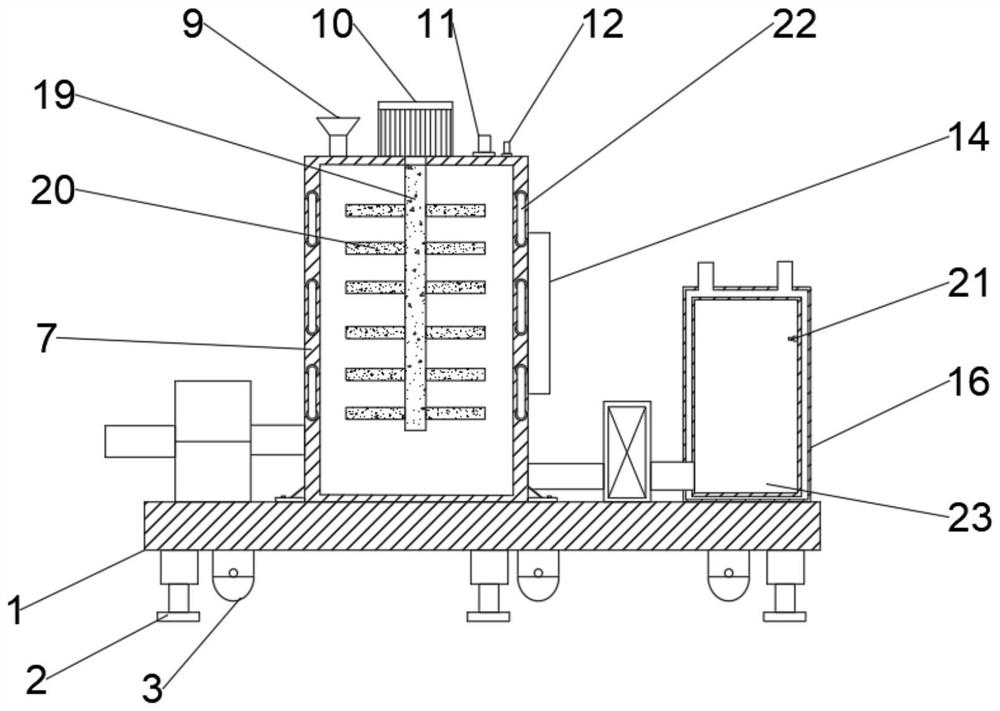

[0021] Embodiment 1: as figure 1 and figure 2 As shown, a kind of radiation cross-linked flame-retardant polyolefin foam material banburying equipment of the present invention includes a base 1 and a cross-linked foam material cooling chamber 23, the bottom of the base 1 is provided with a pulley 3, and the pulley 3 is fixed on the base 1, the bottom of the base 1 is also provided with a hydraulic cylinder 2, the hydraulic cylinder 2 is fixedly connected with the base 1, the top end of the base 1 is provided with an air compressor support 4, and the top of the air compressor support 4 is provided with an air compressor 5 , one side of the air compressor 5 is provided with a conduit, the other side of the air compressor 5 is provided with a mixing chamber 7, one side of the air compressor 5 is provided with a control box 6, and the top of the control box 6 is provided with an air compression regulator The knob 8 and the bottom of the control box 6 are provided with a safety v...

Embodiment 2

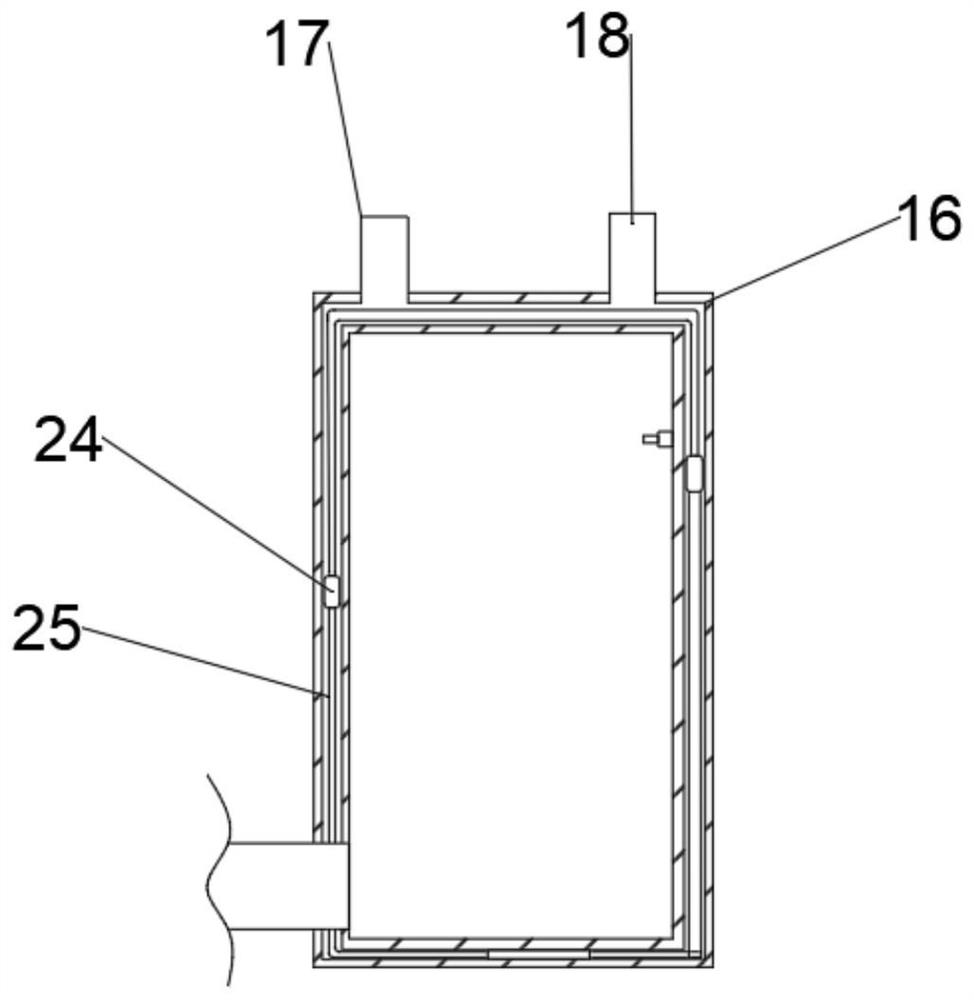

[0026] Embodiment 2: as figure 1 , figure 2 and image 3 As shown, a kind of radiation cross-linking flame-retardant polyolefin foam material banburying equipment of the present invention includes a cooling box 16, which is characterized in that the cooling box 16 is arranged on one side of the water pump 15, and the top of the cooling box 16 is provided with an inlet Water outlet 17, water outlet 18 is provided on one side of water inlet 17, through the cooling box 16 of visual field, realize the cooling function of equipment, reach the effect of cooling the material after banburying.

[0027] Wherein, the inside of the cooling box 16 is provided with a cross-linked foam material cooling bin 23, and the bottom side of the cross-linked foam material cooling bin 23 passes through the shell of the cooling box 16 to be sealed and connected with the water pump 15 through the metal conduit provided. A liquid level display 21 is provided in the cooling chamber 23 of the interlink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com