Miniature flapping wings capable of realizing large deformation and high control moment generation

A technology for controlling torque and large deformation, which is applied in non-electrical variable control, vehicle position/route/height control, attitude control, etc. It can solve the problems of small aerodynamic control torque, difficulty in maintaining efficient attitude control, and small control rudder effect. Achieve the effect of increasing the change range, significant change in angle of attack, and improved maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

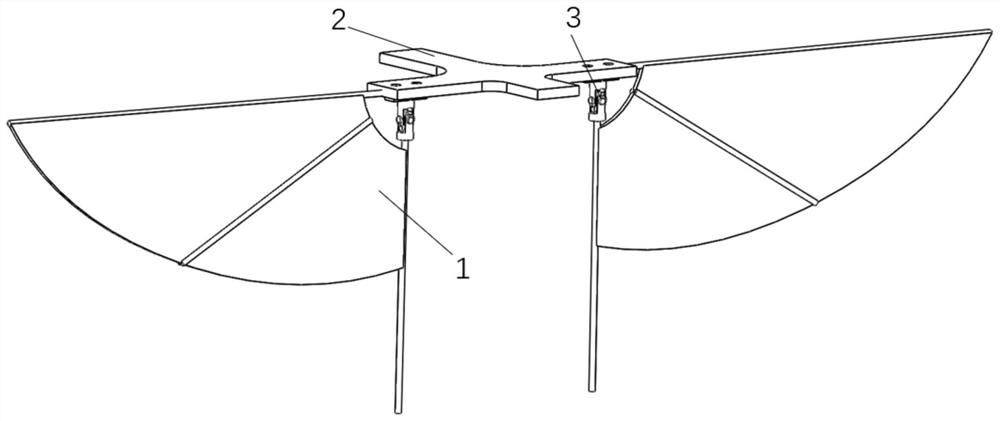

[0031] A miniature flapping wing that can realize large deformation and high control torque generation, such as figure 1 Shown, comprise flapping wing 1, fixing device 2 and changing device 3.

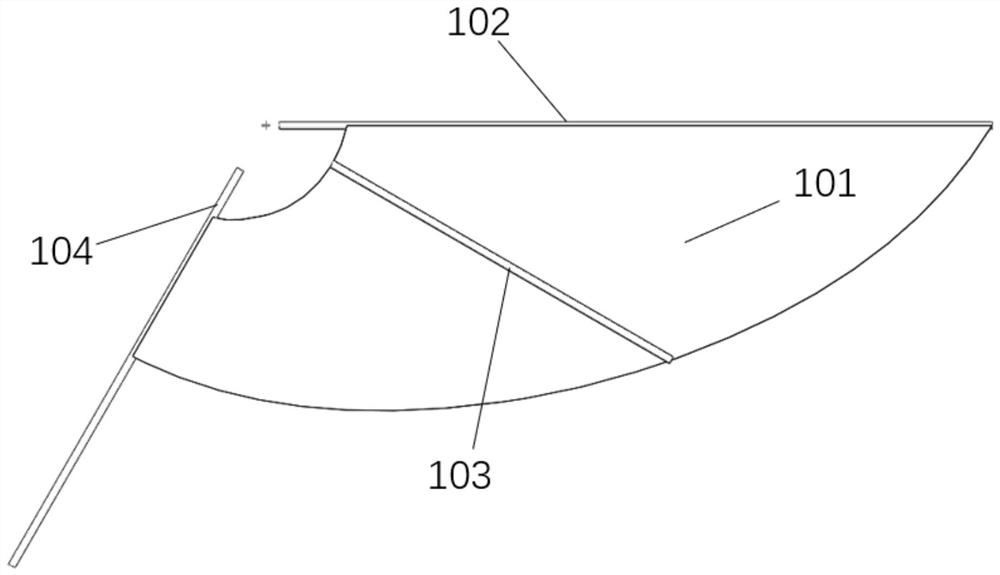

[0032] Such as figure 2As shown, the flapping wing includes a flexible membrane 101 , a horizontal beam 102 , an oblique elastic rod 103 and a wing root elastic rod 104 . The flexible membrane 101 is made of polyimide material, which is in the shape of a bionic flapping wing. The leading edge is horizontal, and the trailing edge is a circular arc shape, and the chord length decreases from the wing root to the wing tip; 102 bonding, one side of the wing root is bonded to the wing root elastic rod 104, and the wing root elastic rod 104 is pasted on the horizontal and straight beam 102 at an angle of 100° to 120° when the flexible wing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com