Packaging receiving-sending all-in-one machine and sampling system

An all-in-one machine and sample bottle technology, which is applied in the directions of packaging, transportation and packaging, and object unstacking, etc., can solve the problems of low work efficiency, artificial counterfeiting, etc., and achieve the effect of avoiding damage or dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

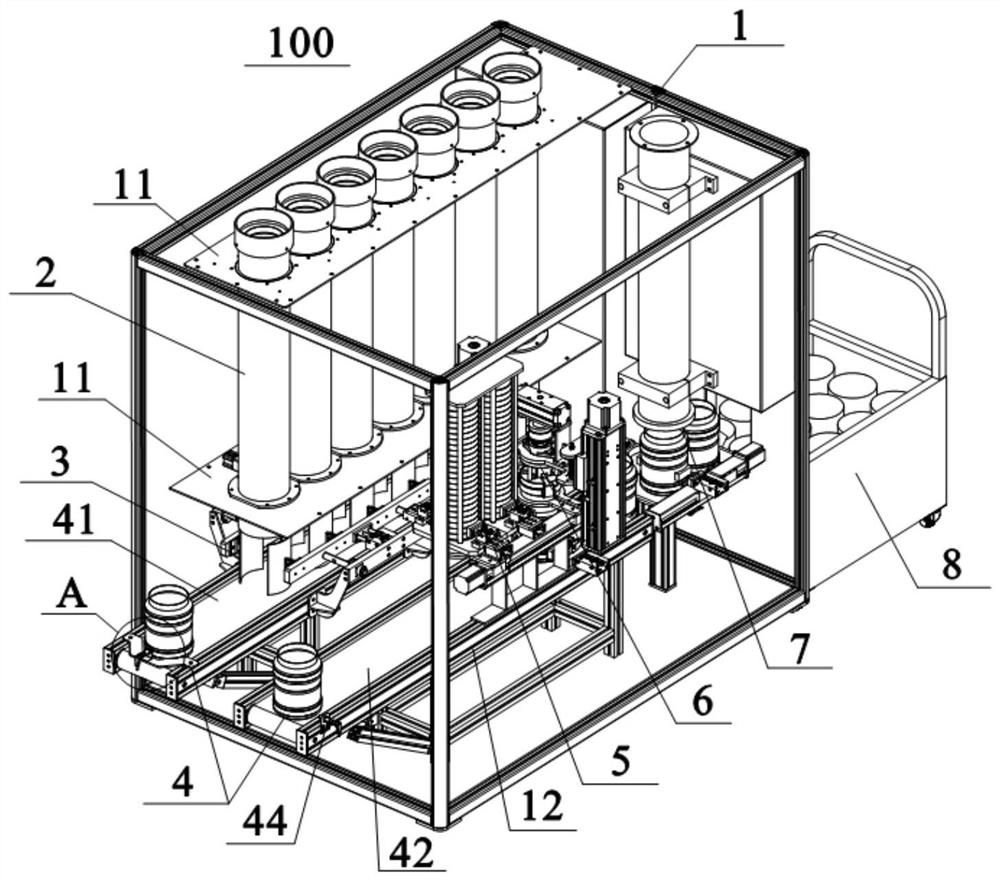

[0057]The embodiment provides a packaging transceiver 100, which can be used for sampling and testing in the production fields of metallurgy, coal mining, cement, food, etc., and can realize the storage, packaging, and receiving and dispatching operations of the sample bottle 800 to facilitate sampling The automation of detection improves work efficiency and reduces the probability of fraud.

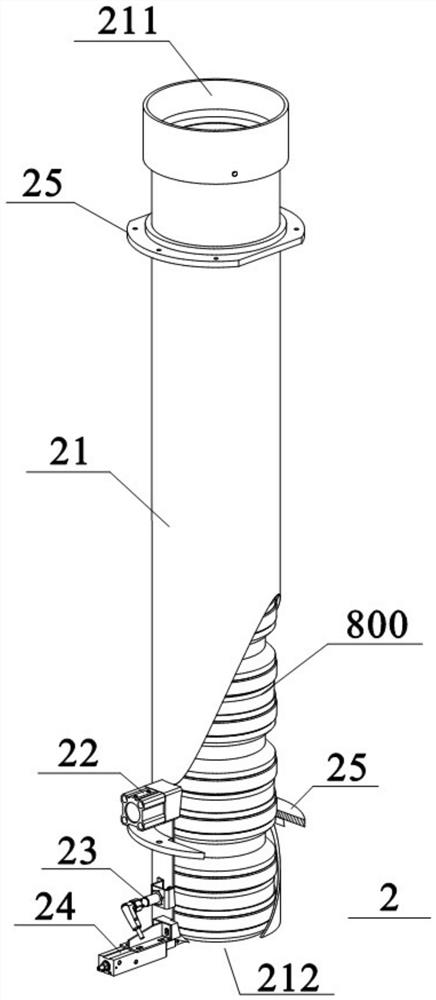

[0058]Such asfigure 1 As shown, the packaged transceiver 100 includes a first storage mechanism 2, a slow-fall mechanism 3, a conveying mechanism 4, a packaging mechanism 6 and a transceiver mechanism 7. The first storage mechanism 2 is used to store empty sample bottles 800, that is, unused sample bottles 800. There may be a plurality of first storage mechanisms 2 arranged side by side to facilitate storage of more sample bottles 800; for example, the first storage mechanism 2 may be arranged in one, two, four, etc. numbers, which are not limited here.

[0059]In other embodiments, the plurality of...

Embodiment 2

[0067]On the basis of embodiment 1, further, such asfigure 1 As shown, the packaged transceiver 100 further includes a frame 1, and the first storage mechanism 2, the slow-fall mechanism 3, the conveying mechanism 4, the packaging mechanism 6 and the transceiver mechanism 7 are all arranged in the frame 1. Specifically, the first storage mechanism 2 is arranged on one side close to the rack 1; the slow-fall mechanism 3 is arranged on the same side and is arranged below the first storage mechanism 2. The packaging mechanism 6 and the transceiver mechanism 7 are arranged on the other side of the frame 1, and the packaging mechanism 6 and the transceiver mechanism 7 are arranged side by side.

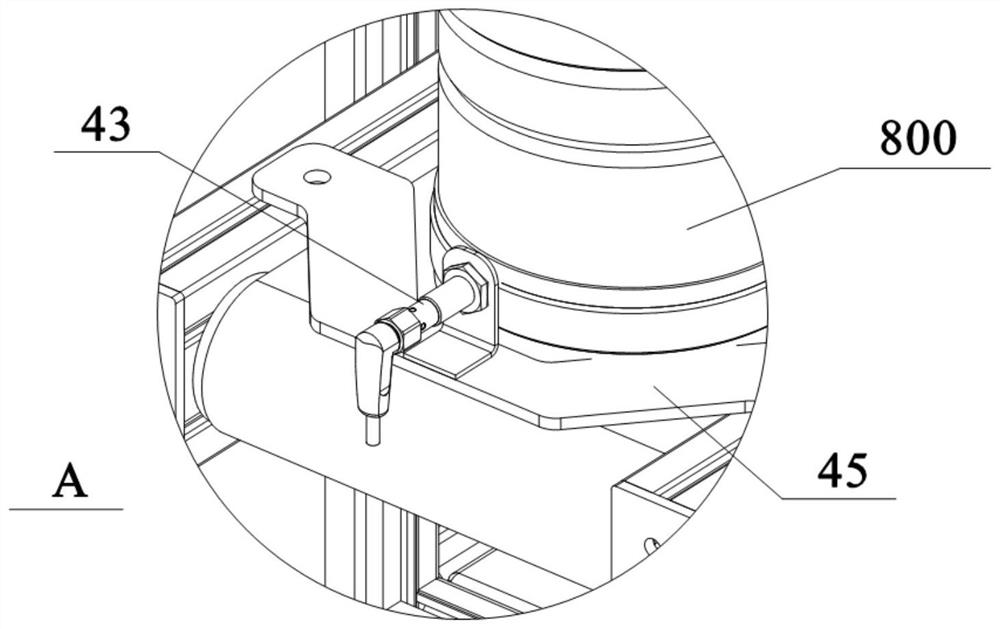

[0068]The conveying mechanism 4 includes a first conveying belt 41 and a second conveying belt 42; the first conveying belt 41 and the second conveying belt 42 are arranged in parallel. The first conveyor belt 41 passes under the first storage mechanism 2; the second conveyor belt 42 passes under t...

Embodiment 3

[0115]Such asPicture 11 As shown, the embodiment also provides a sampling system, including a manipulator 200, a code reading and writing device 300, a sample preparation device 400, a first positive and negative pressure transceiver device 600, a second positive and negative pressure transceiver device 700, and the first embodiment. Or the packaged transceiver 100 provided in the second embodiment.

[0116]In some embodiments, the package transceiver 100, the manipulator 200, the code reading device 300, the sample preparation device 400, the first positive and negative pressure transceiver device 600, and the second positive and negative pressure transceiver device 700 can all be connected to the same master The same main controller coordinates the packaging of the integrated transceiver 100, the manipulator 200, the code reading device 300, the sample preparation device 400, the first positive and negative pressure transceiver device 600, and the second positive and negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com