Method for producing cobaltosic oxide by calcining aluminum and manganese doped small-particle-size cobalt carbonate

A technology of cobalt tetroxide and cobalt carbonate, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of corroding equipment, increasing the content of magnetic foreign matter, and unusable products, and achieves uniform distribution of doping elements, uniform morphology, and magnetic foreign matter. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

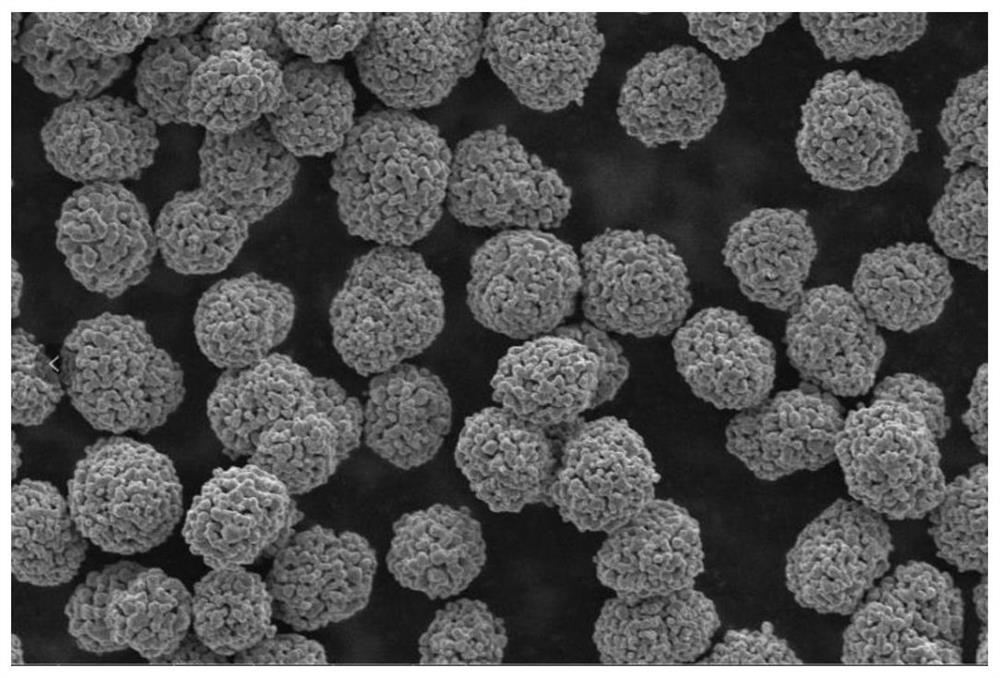

[0018] Put small particle size (4 microns) cobalt carbonate doped with aluminum and manganese (aluminum 6000ppm; manganese 1000ppm) into the burning boat; set the temperature of the roller kiln to 2 stages: the first stage feeds at 200°C, and the holding time is 4 hours , 2 hours to 400 ° C, heat preservation for 6 hours, discharge, and then put into the rotary kiln, the temperature of the rotary kiln is set to 710 ° C, adjust the parameters so that the particles stay in the kiln for 4 hours, and finally get Al-Mn doped Cobalt tetroxide product with uniform appearance, such as figure 1 , tap density 2.20, specific surface area 3.45, magnetic foreign matter 50ppb.

Embodiment 2

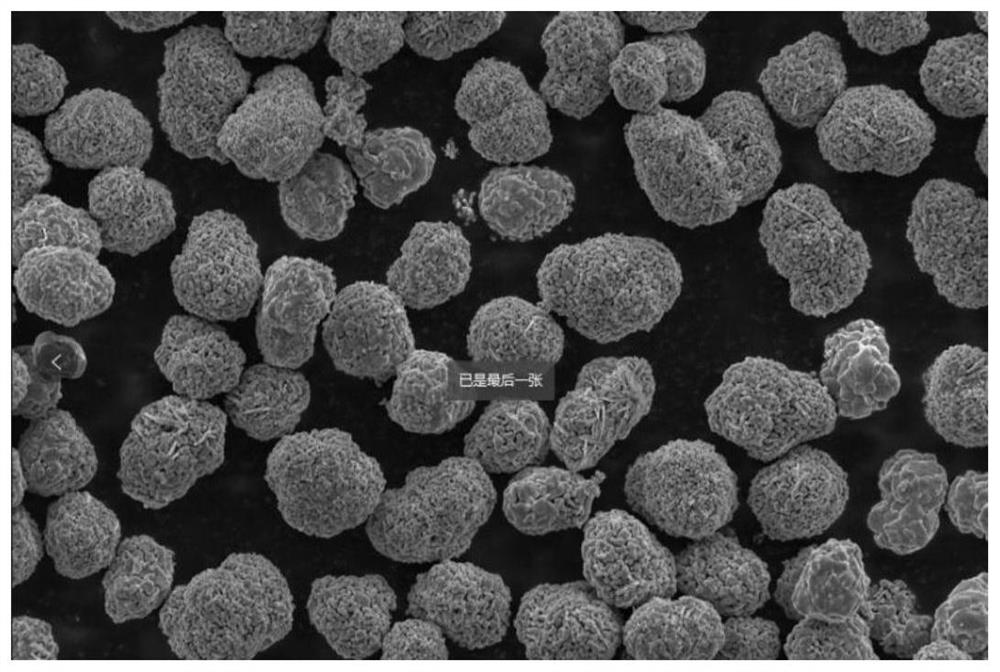

[0020] Put the cobalt carbonate with small particle size (5 microns) doped with aluminum and manganese (7000ppm aluminum; 2000ppm manganese) into the burning boat; set the temperature of the roller kiln to 2 stages: the first stage feeds at 100°C, and the holding time is 3 hours , heat up to 500°C for 1 hour and hold for 7 hours, discharge the material, and then put it into the rotary kiln. The temperature of the rotary kiln is set to 700°C, and the parameters are adjusted so that the residence time of the particles in the kiln is 5 hours, and finally the aluminum-manganese-doped Cobalt tetroxide product with uniform appearance, tap density 2.06, specific surface area 3.97, magnetic foreign matter 40ppb.

Embodiment 3

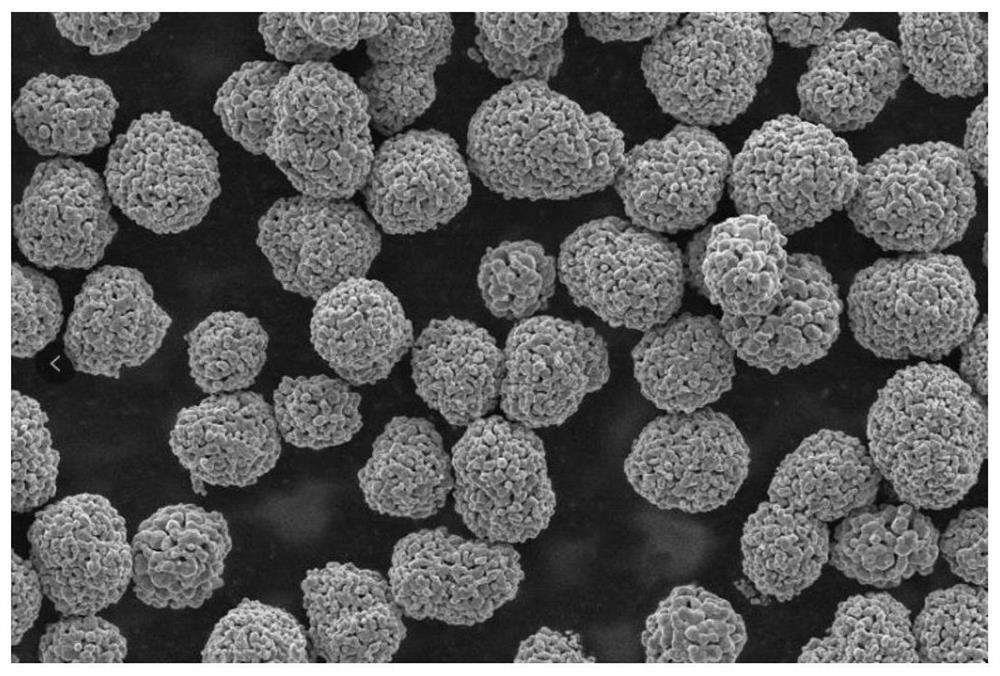

[0022] Put cobalt carbonate with small particle size (4 microns) doped with aluminum and manganese (aluminum 8000ppm; manganese 1000ppm) into the burning boat; set the temperature of the roller kiln to 2-stage method: the first stage feeds at 300°C, and the holding time is 5 hours , 3 hours to 300 ° C, heat preservation for 5 hours, discharge, and then put into the rotary kiln, the temperature of the rotary kiln is set to 750 ° C, adjust the parameters so that the particles stay in the kiln for 3 hours, and finally get Al-Mn doped Cobalt tetroxide product with uniform appearance, tap density 2.33, specific surface area 2.41, magnetic foreign matter 45ppb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com