Preparation method of flame-retardant polypropylene material

A flame retardant polypropylene and polypropylene technology is applied in the field of preparation of flame retardant polypropylene materials, which can solve the problems affecting the weather resistance of materials, residual peroxides, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

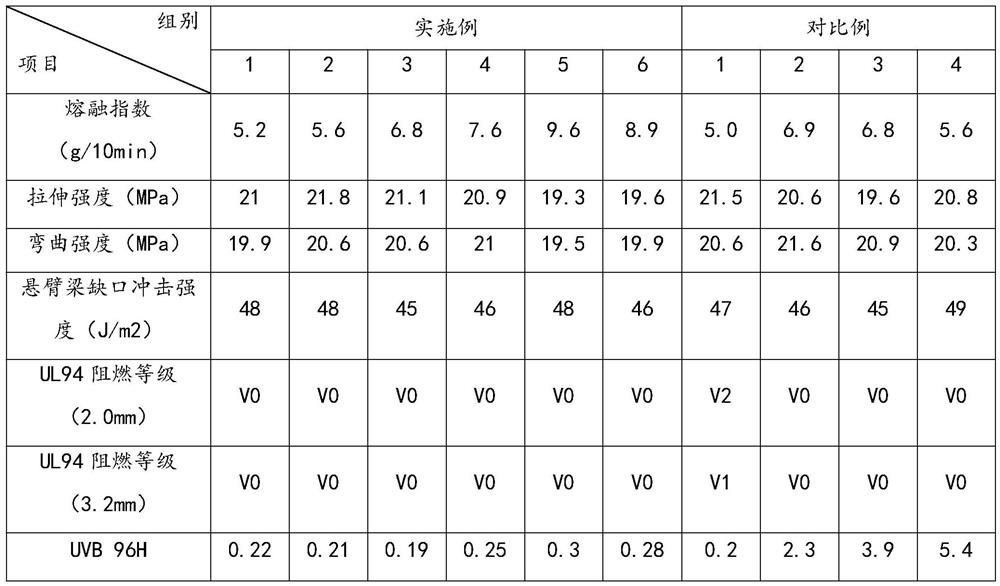

Examples

Embodiment 1

[0032] A preparation method of flame-retardant polypropylene material, comprising the following steps:

[0033] S1. Fully mix K800386 parts, 0.1 parts of peroxide masterbatch, 0.3 parts of antioxidant, and 0.3 parts of lubricant in a high-mixing pot, and melt, plasticize and blend the obtained mixture A through a twin-screw extruder , then extrude and granulate to obtain polymer particles B, the used twin-screw extruder L:D=35:1, the rotating speed of the screw is 400r / min, the feeding speed 12rpm, the temperature in each district of the extruder is set to : Zone 1 200°C, Zone 2 180°C, Zone 3 180°C, Zone 4 185°C, Zone 5 180°C, Zone 6 185°C, Zone 7 180°C, Zone 8 180°C, Zone 9 180°C, Zone 10 160°C ;

[0034] S2. Premix the polymer particle B obtained after pretreatment with 14 parts of flame retardant, 0.2 part of antioxidant, 0.3 part of lubricant, 0.3 part of light stabilizer, and 0.6 part of carbon black in a high-mixing pot , the time of mixing is 10min, obtains mixture C,...

Embodiment 2

[0036] The specific operation was carried out as in Example 1, except that the mass fraction of the flame retardant added in step S2 was 20 parts.

Embodiment 3

[0038] The specific operation is carried out according to Example 1, except that the mass fraction of the peroxide masterbatch added in step S1 is 0.4 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap