Cast single crystal seed crystal preparation method

A single crystal and seed crystal technology, which is applied in the field of single crystal seed crystal preparation technology, can solve the problems such as difficult to distinguish the head, uneven reaction on the surface of cast single crystal seed crystal, and difficult to distinguish the head and tail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred solution is as Figure 1 to Figure 6 Shown, a kind of cast single crystal seed crystal preparation method comprises the steps:

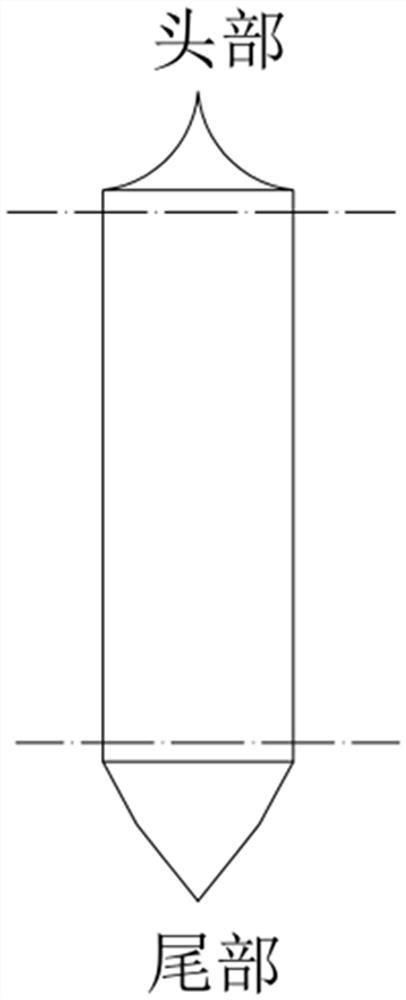

[0035] S1: if figure 1 As shown in , remove the head and tail of the Czochralski rod;

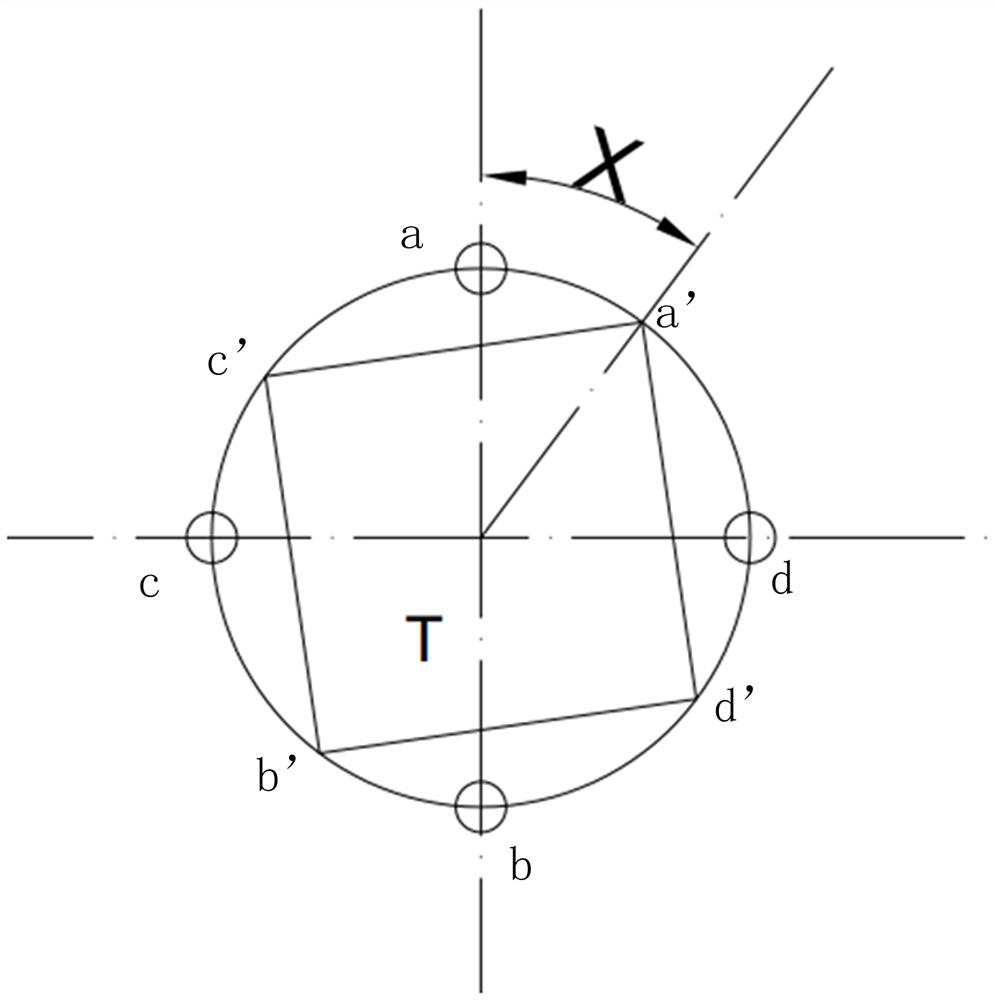

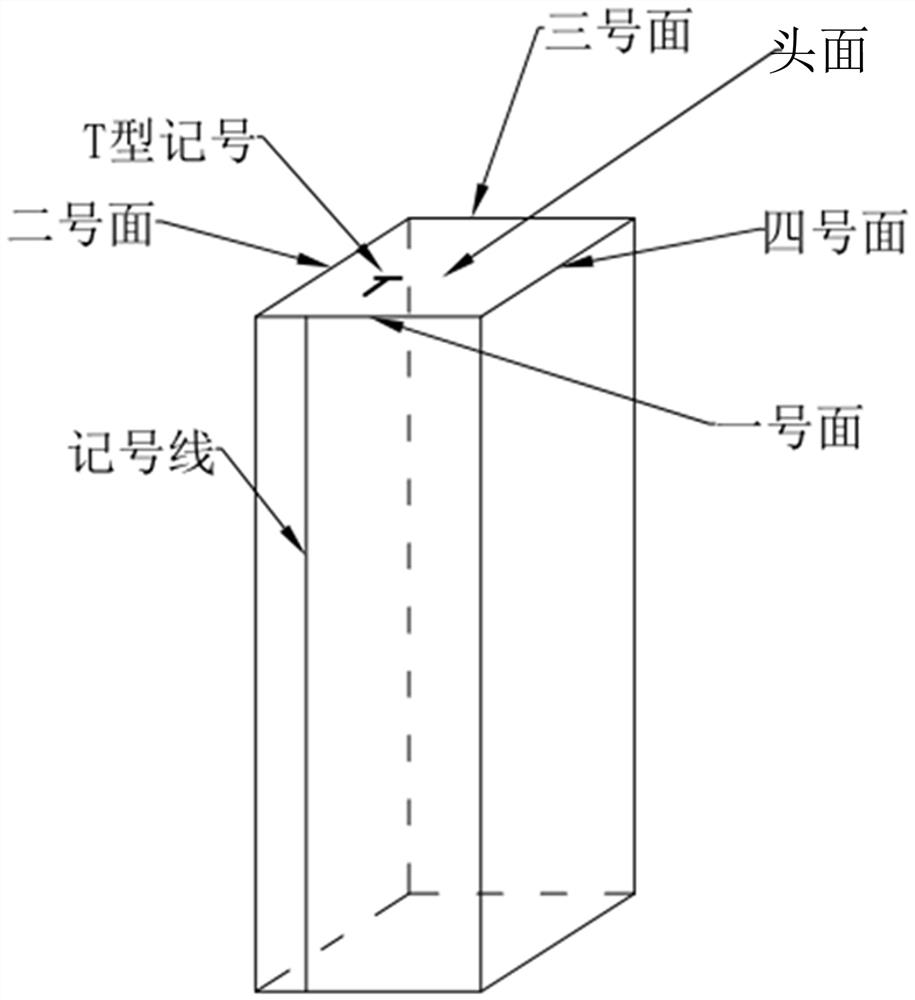

[0036] S2: if figure 2 As shown, the cutting surface of the head of the CZ single crystal rod is defined as the head surface, and the cutting surface of the tail of the CZ single crystal rod is defined as the tail surface; use a diamond pen to engrave a "T" logo on the head surface, "T The depth of the font mark is H, and the value range of H is 0.01-0.02mm. Taking the "T" shape as the standard, the four ridges of the "T" are a, b, c and d respectively; Viewed from the perspective of the head and face, a, b, c, and d form a square, and the square is rotated by an X angle based on the center of the head face, and a, b, c, and d are rotated to the positions of a', b', c', and d' respectively; The ridges corresponding to a', b', c' and d' ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com