A connection structure between a suspended monorail and a road bridge cover beam

A technology for highway bridges and connecting structures, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as insufficient bearing capacity of joints, weakening of flange plate bearing capacity, inconvenient construction process, etc., and achieve reliable and effective mechanical performance Guaranteeing and increasing bridge space utilization, and the effect of simple and clear force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

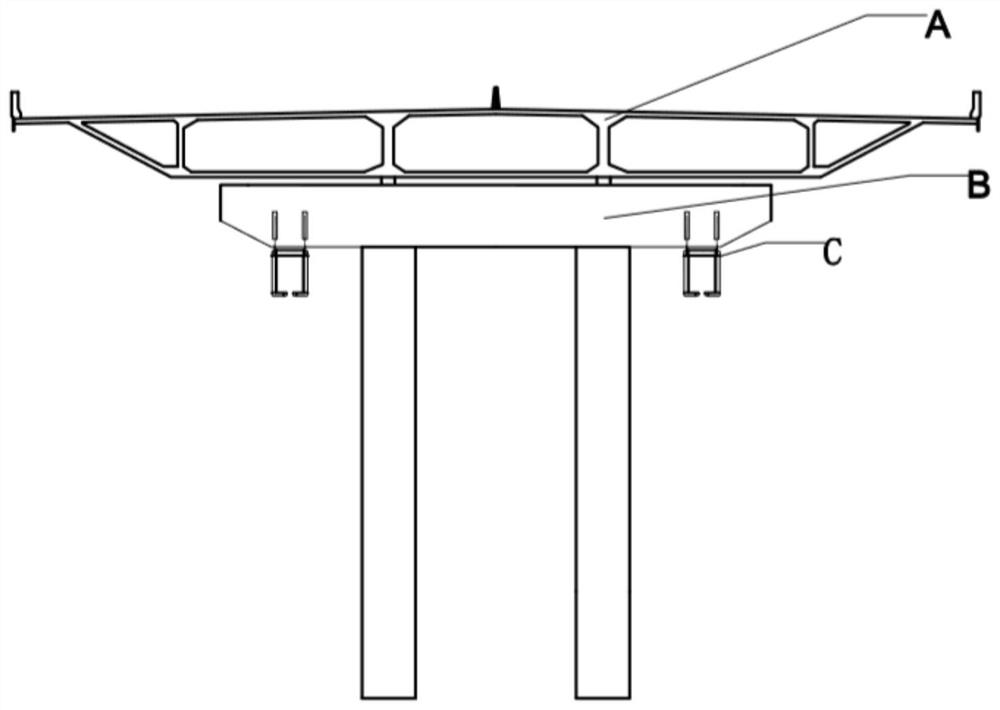

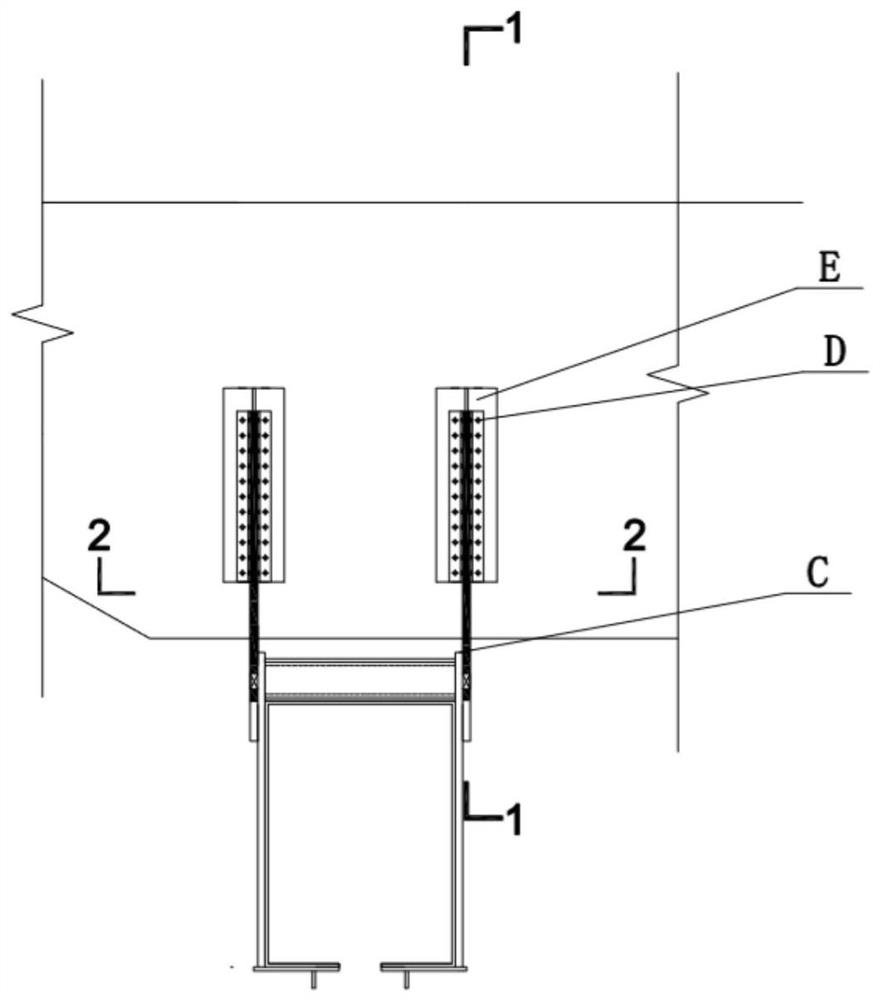

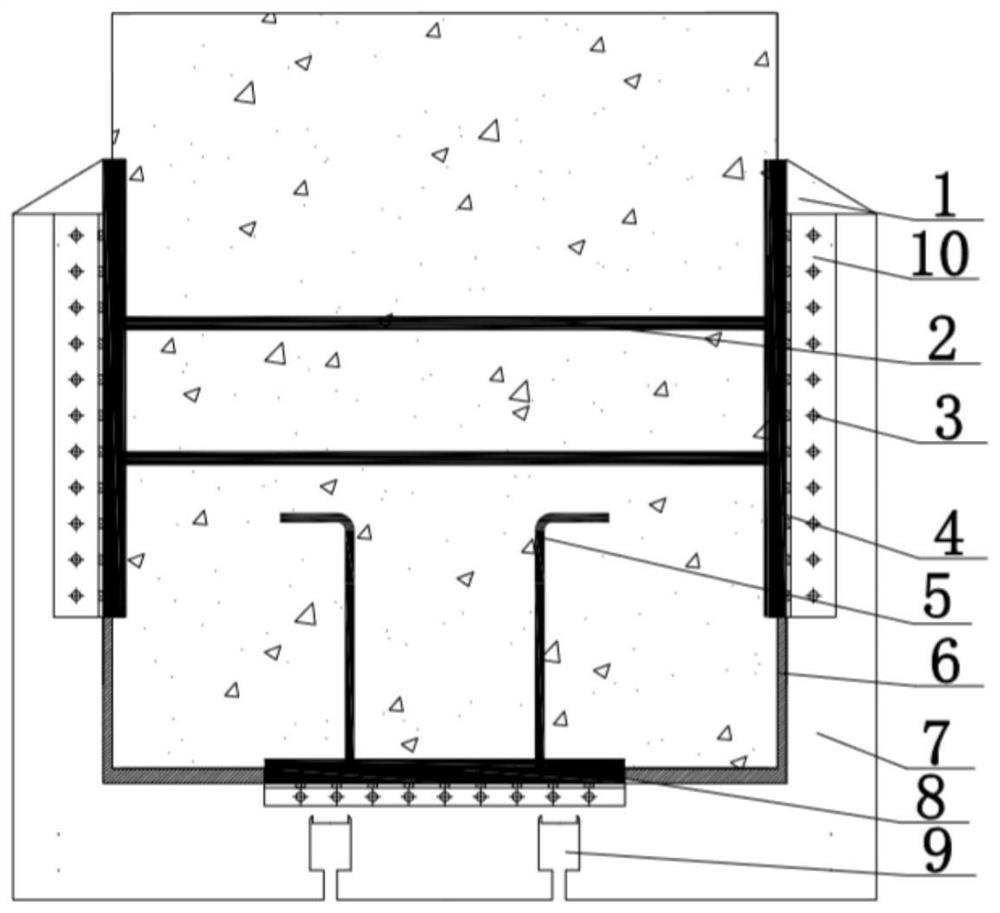

[0037] Such as Figure 1 to Figure 4 As shown, the present invention relates to a connection structure between a suspended monorail and a highway bridge cover beam, which is used for stably connecting the highway bridge cover beam and the suspended monorail, increasing the space utilization rate of the bridge, and relieving traffic pressure. The structure mainly includes reserved part E and connecting part D. The highway bridge box girder plate A is used to bear the upper part of the vehicle lane load bridge superstructure, which belongs to the prior art and will not be described in detail. The transition component cover beam B is installed at the bottom of the box girder slab A of the highway bridge, and is used to transfer the load of the vehicle lane to the bridge pier, and is also used to bear the self-weight of the suspended track beam C. The suspended track beam C is arranged at the bottom of the transition member cover beam B.

[0038] Transition member cover beam B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com