Valve core displacement-variable control device for construction machinery

A technology of spool displacement and construction machinery, which is applied in the direction of valve device, non-electric variable control, valve operation/release device, etc. It can solve problems such as unstable circuit pressure, affecting the stability of hydraulic circuit, and inconvenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

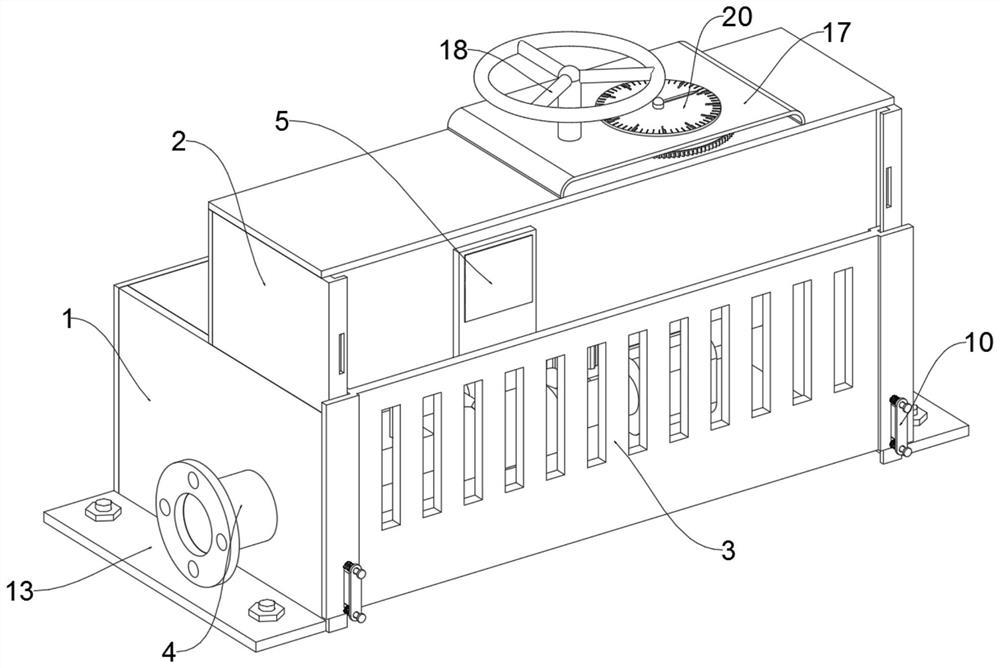

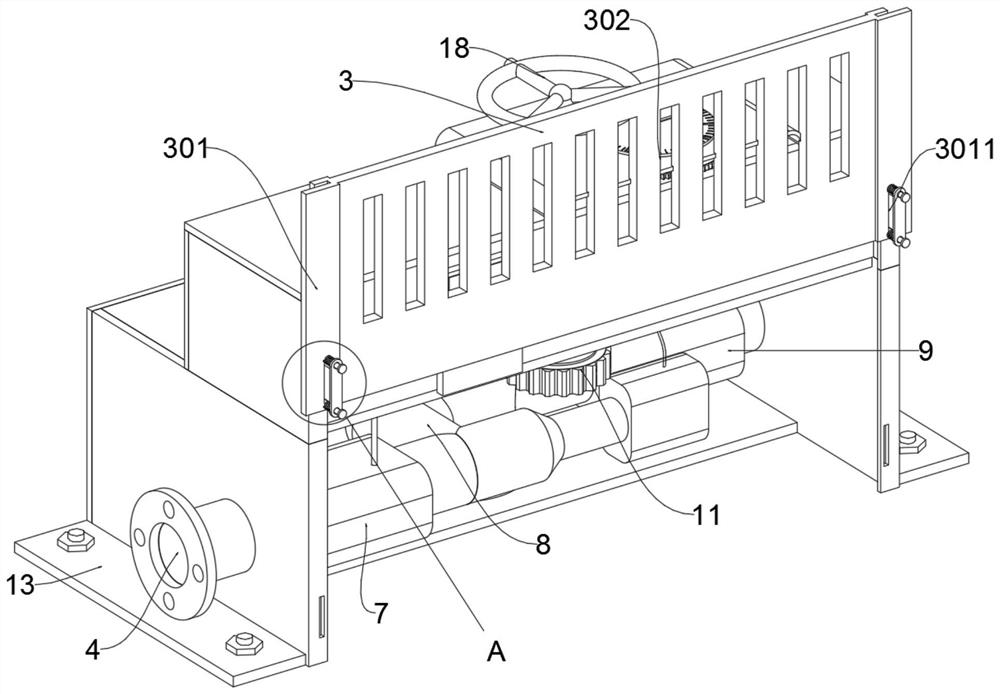

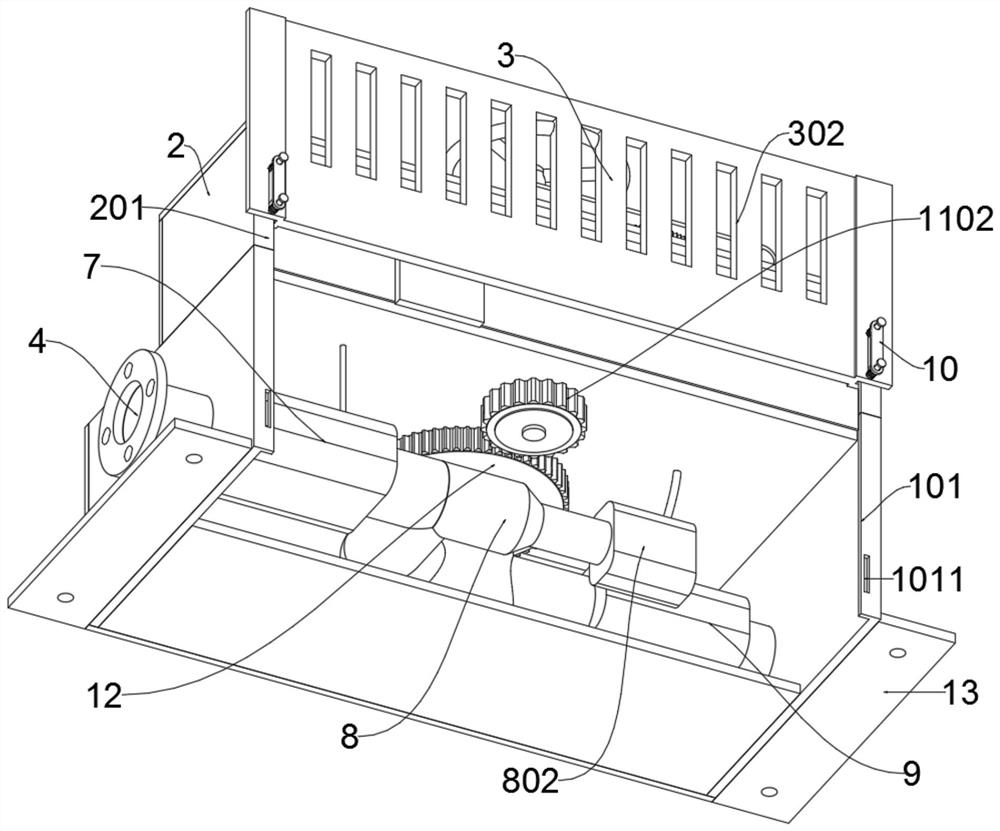

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036]The invention provides a valve core displacement variable control device for construction machinery, which includes a lower protective frame 1, a heat dissipation plate 3, a liquid inlet 4, a display screen 5, a transmission pipe 8, a pressure detector 9, an adjustment switch 10, and a transmission Part 11, adjusting gear 12, mounting seat 13, controller 15, valve body 16, upper shell cover 17, hand wheel 18, driven metering wheel 19, metering disc 20; the upper surface of the lower protective frame 1 is connected by welding The lower surface of the protective frame 2; the cooling plate 3 is slidably connected to the front side of the lower protective frame 1 and the upper protective frame 2; the liquid inlet 4 passes through the left side plate of the lower protective frame 1 and is fixedly connected to the flow monitor 7; the transmission pipe The left side of 8 is fixedly connected to the right outlet of flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com