Push rod displacement monitoring mechanism of vehicle clutch

A displacement monitoring and clutch technology, applied in the field of clutches, can solve problems such as insufficient compact space, and the detection accuracy needs to be improved, and achieve the effects of simple structure improvement, signal delay improvement, and error reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

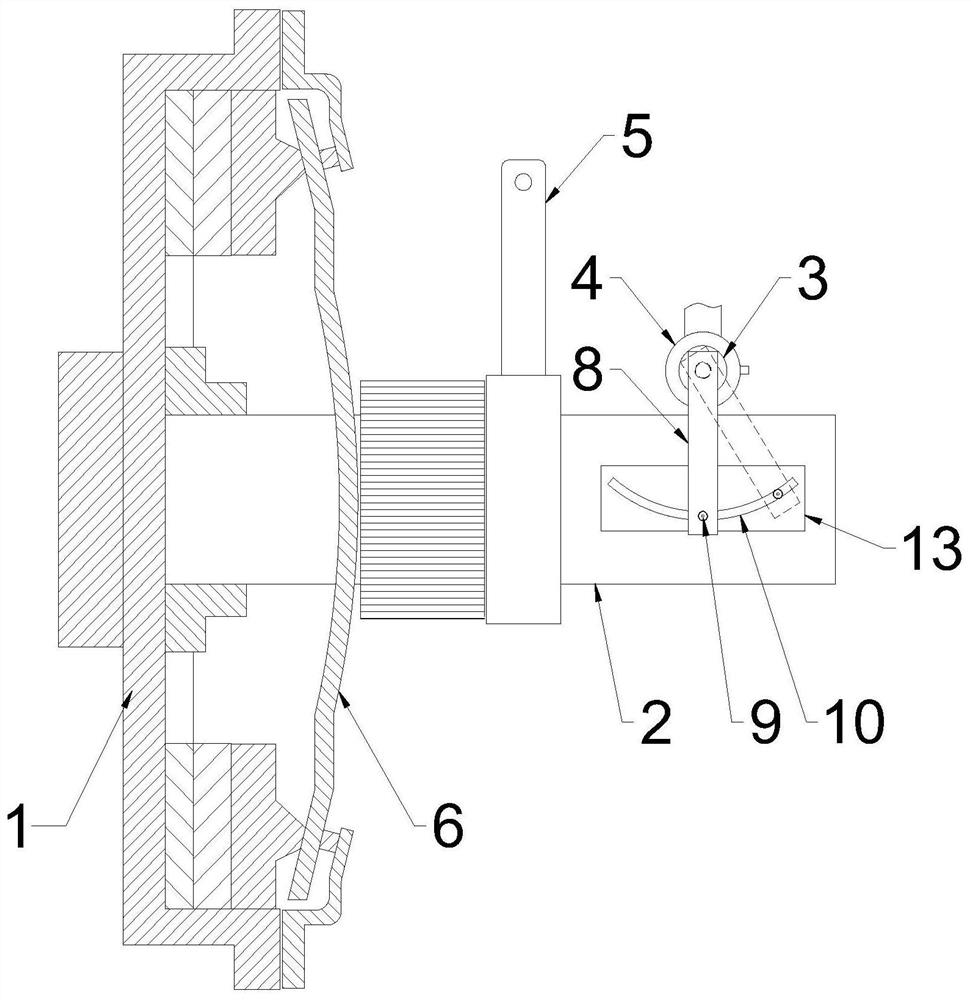

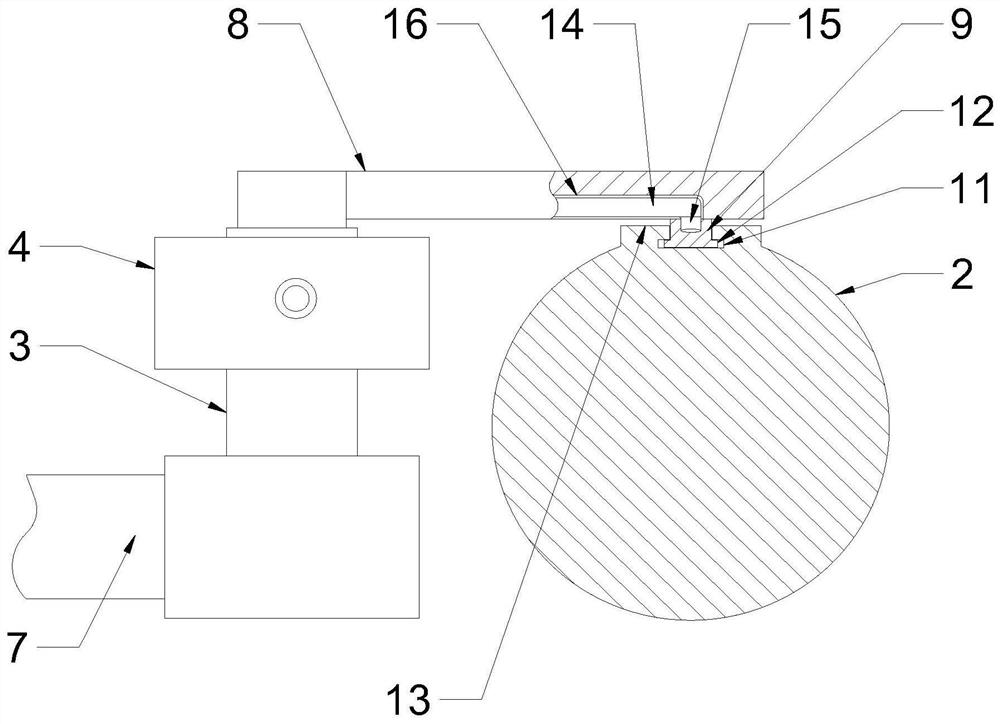

[0024] Such as figure 1 and figure 2 As shown, a push rod displacement monitoring mechanism of a vehicle clutch includes a clutch 1, a push rod 2, a rotating column 3 and an encoder 4. The push rod 2 is slidably installed on the clutch 1, and the push rod 2 is connected to the separation rocker of the clutch. The arm 5 and the push rod 2 can receive the thrust transmitted from the clutch pedal and the separation rocker arm 5 to squeeze the diaphragm spring 6 of the clutch to deform. Rotary column 3 is mounted on a bracket 7 of the vehicle chassis in a rotatable manner. The central key is connected with a connecting rod 8, and the other end of the connecting rod 8 is provided with a follower 9, and the push rod 2 is formed with an arc-shaped main limiting groove 10 that cooperates with the follower 9. The columns 3 have a common center, and the follower 9 is inserted into the main limiting groove 10. When the push rod 2 is translated, the follower 9 of the connecting rod 8 m...

Embodiment 2

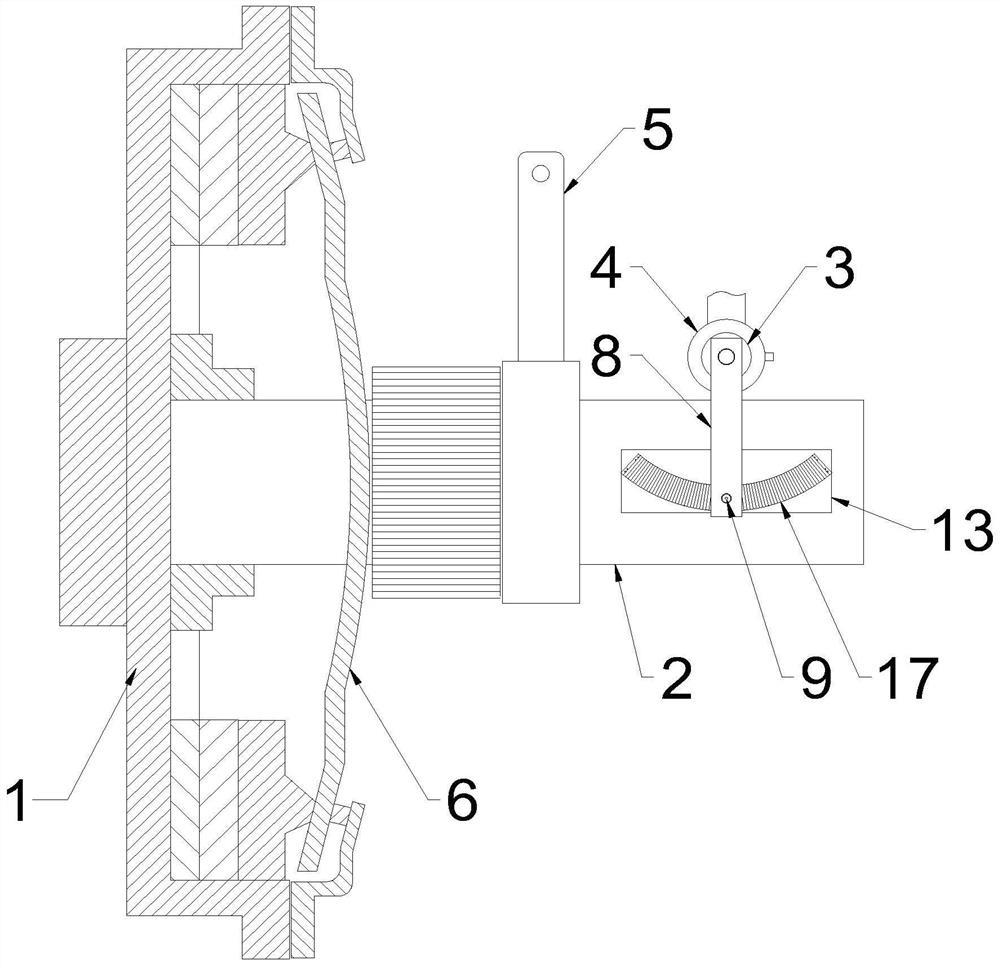

[0030] The difference between this embodiment and embodiment 1 lies in the difference of the dust-proof structure, such as image 3 As shown, the monitoring mechanism nails or glues an accordion-shaped dust cover 17 on the convex surface 13 of the connecting rod. The material of the dust cover 17 is a flexible waterproof fabric, and the dust cover 17 can cover the main limiting groove 10. Wherein, two dustproof covers 17 are installed symmetrically on the convex surface 13, and one end of the dustproof cover 17 is fixed at the arc-shaped end of the main limiting groove 10, and the other end is fixed on the connecting rod 8, when the connecting rod 8 rotates The dust cover 17 can be alternately stretched or folded, for example: when the connecting rod 8 folds the left dust cover, the right side dust cover is automatically stretched by the connecting rod, so that the main limiting groove 10 is always covered by the dust cover. Cover 17 covers, and isolation dust enters in the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com