Tunnel aerodynamic effect motion model test system and method in high-cold and high-altitude environment

A technology of tunnel model and test system, which is applied in the field of dynamic model test system for tunnel aerodynamic effects in high-cold and high-altitude environments to achieve accurate effects in high-cold and high-altitude environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

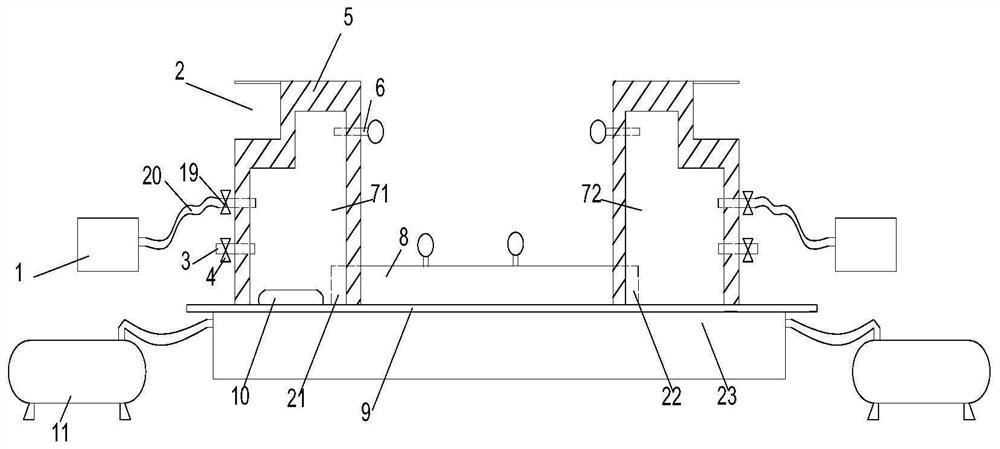

[0061] Such as image 3 As shown, the simulated tunnel entrance and exit 21 are all H meters above sea level, and the temperature is an alpine and high altitude environment of T1. (both ends should be the same)

[0062]First, through the tunnel entrance and exit 21 on-the-spot measurement, consulting the atmospheric pressure gauge and other methods, the atmospheric pressure obtained when the altitude is H meters and the temperature is T1 is P1; machine and refrigeration system, so that the temperature in the first heat preservation pressure chamber 71 and the second heat preservation pressure chamber 72 reaches T1, and the atmospheric pressure reaches P1; Manometer 6, observe whether parameters such as temperature and pressure meet the requirements and remain stable; finally, if it is stable, start the air cannon 11 to start the dynamic model test.

Embodiment 2

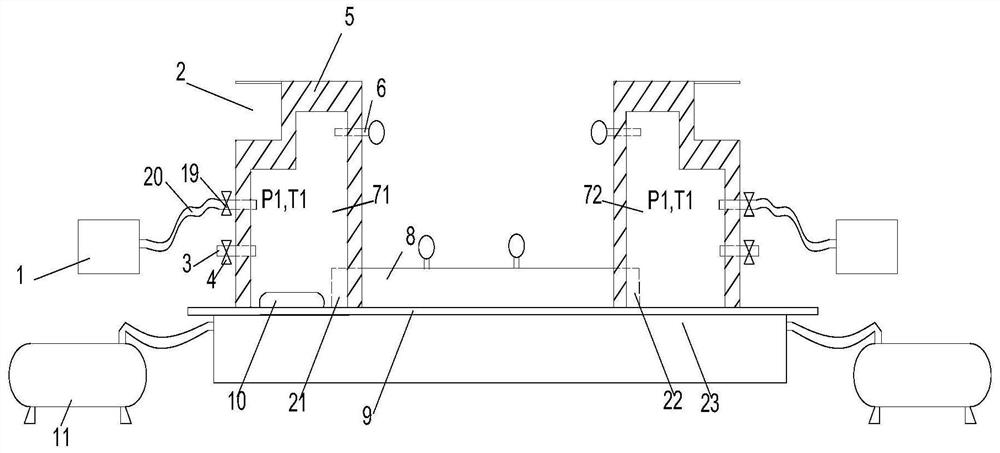

[0064] Such as Figure 4 As shown, the simulated tunnel entrance and exit 21 are all H meters above sea level, and the temperature is respectively the alpine and high altitude environment of T2 and T3.

[0065] First, through the tunnel entrance and exit 21 on-the-spot measurement, consulting the atmospheric pressure gauge and other methods, obtain the atmospheric pressure P2 and P3 when the altitude H meters and the air temperature are respectively T2 and T3; then, start the first heat preservation pressure chamber 71 and the second heat preservation pressure The air compressor and refrigeration system in the warehouse 72 make the temperature in the first heat preservation pressure chamber 71 reach T2, the atmospheric pressure reach P2, the temperature in the second heat preservation pressure chamber 72 reach T3, and the atmospheric pressure reach P3; again, check the heat preservation pressure chamber 7 With the thermometer 6 on the tunnel, observe whether parameters such as...

Embodiment 3

[0067] Such as Figure 5 As shown, the simulated tunnel entrance and exit 21 are H1 and H2 meters above sea level, and the temperature is T4 and T5 respectively in the high-cold and high-altitude environment.

[0068] First, through the tunnel entrance and exit 21 on-the-spot measurement, consulting the atmospheric pressure gauge, etc., obtain the atmospheric pressure P4 and P5 when the altitude is respectively H1 and H2 meters, and the temperature is T4 and T5 respectively; then, start the first thermal insulation pressure chamber 71 and The air compressor and refrigeration system of the second thermal insulation pressure chamber 72 make the temperature in the first thermal insulation pressure chamber 71 reach T4, the atmospheric pressure reaches P4, the temperature in the second thermal insulation pressure chamber 72 reaches T5, and the atmospheric pressure reaches P5; again, check Insulation pressure chamber 7 and the thermometer 6 on the tunnel observe whether parameters s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap