A gas chromatography device

A gas chromatographic device and gas technology, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as reducing the tightness of the connection between the gas column and the injection port, the sealing gasket affecting the sealing performance and life, and the vibration of the gas column. Increase the range of use, improve the sealing effect, and increase the effect of the sealing path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached to the following Figure 1-4 This application will be described in further detail.

[0037] The embodiment of the present application discloses a gas chromatography device.

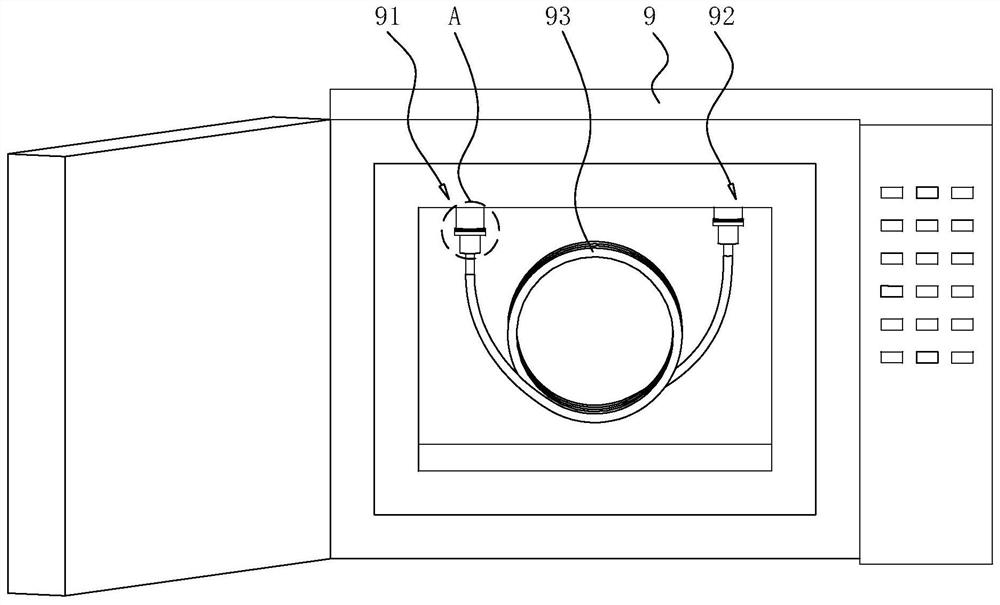

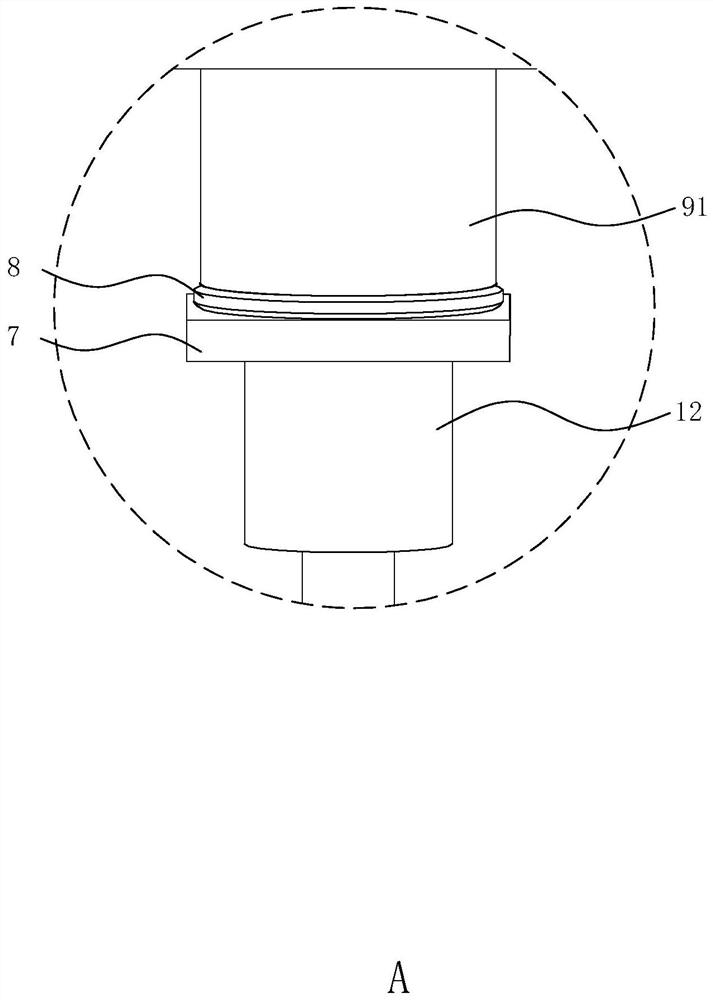

[0038] refer to figure 1 A gas chromatography device comprises a gas chromatography device body 9, the top of the inner wall of the gas chromatography device body 9 is fixedly connected with a sample inlet 91 and a sample outlet 92, and a gas column 93 is placed inside the gas chromatography device body 9, and the gas column 93 is hollow Glass tube-shaped, one end of the gas phase column 93 is communicated with the sample inlet 91, and the other end is communicated with the sample outlet 92, and a fixed tube 1 is provided between the end of the gas phase column 93 and the sample inlet 91 and the sample outlet 92, and the gas phase column 93 For the monitoring of ethanol gas.

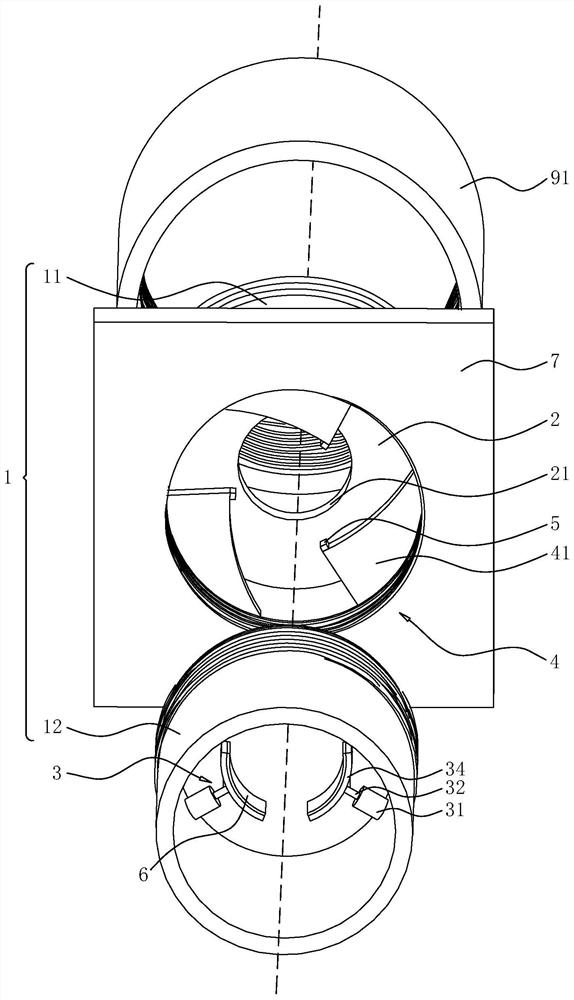

[0039] refer to figure 2 and image 3 , the fixed tube 1 is provided with a fixed component 3 and a limit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com