Negative electrodes, electrochemical devices and electronic devices

An electrochemical and negative electrode technology, applied in the field of electrochemical energy storage, can solve problems such as puncture and short-circuit risks, and achieve the effect of avoiding short-circuit risks and ensuring safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

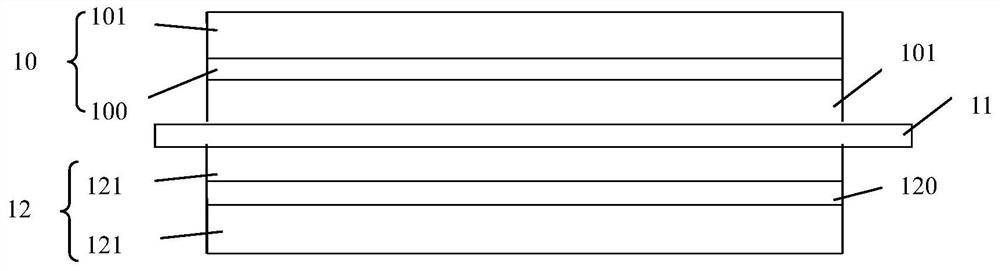

[0070] Preparation of the positive electrode sheet: dissolve the positive active material lithium cobaltate, the conductive agent conductive carbon black, and the binder polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) at a weight ratio of 97.6:1.1:1.3 solution to form positive electrode slurry. Aluminum foil was used as the positive electrode collector, and the positive electrode slurry was coated on the positive electrode collector with a coating thickness of 50 μm. After drying, cold pressing, and slitting, the positive electrode sheet was obtained.

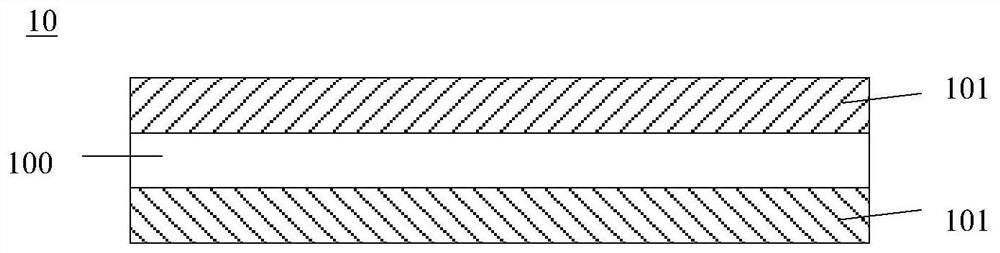

[0071] Preparation of the negative electrode: Dissolve the negative electrode active material artificial graphite, the porous material mesophase carbon microspheres and the binder styrene-butadiene rubber in deionized water at a weight ratio of 98.2:0.5:1.3 to form the negative electrode slurry. Copper foil with a thickness of 10 μm was used as the negative electrode current collector, and the negative electrode slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com