Heat regeneration system of combined heat and power cogeneration unit

A cogeneration unit and heat recovery system technology, applied in the direction of electric components, mechanical equipment, electromechanical devices, etc., can solve the problems of large volume, no peripheral heat production recovery system, complex structure, etc., and achieve the realization of cogeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

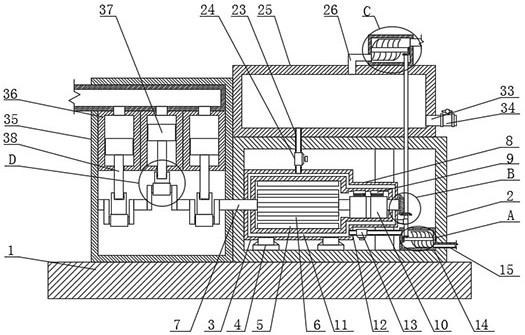

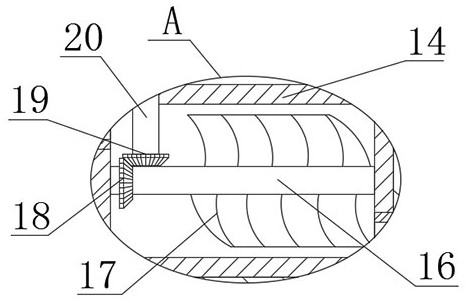

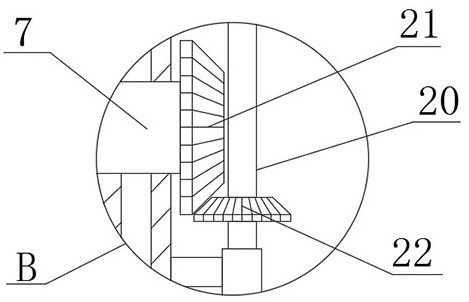

[0026] refer to Figure 1-5 , a heat recovery system for a combined heat and power unit, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected to an organic case 2, a microcomputer 3 is fixedly connected to one side of the inner wall of the case 2, and the bottom of the microcomputer 3 is fixedly connected to a support foot 4 , the legs 4 are fixedly connected to the inner wall of the bottom of the cabinet 2, the inner wall of the microcomputer 3 is fixedly provided with a stator 5, the stator 5 is rotated and provided with a rotor 6, the rotor 6 is fixedly sleeved with a first rotating shaft 7, and the microcomputer 3 An insulating cover 8 is fixedly connected to one side of the insulating cover 8, and a brush 9 is fixedly connected to the inner wall of the top of the insulating cover 8. One end of the first rotating shaft 7 extends to the outside of the insulating cover 8, and the first rotating shaft 7 in the insulating cover 8 is fixedly sleeved. ...

Embodiment 2

[0036] refer to Figure 1-5, a heat recovery system for a combined heat and power unit, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly welded with an organic case 2, one side of the inner wall of the case 2 is fixedly connected with a microcomputer 3 by screws, and the bottom of the microcomputer 3 is fixedly welded with a support The feet 4 and the supporting feet 4 are fixedly connected on the inner wall of the bottom of the chassis 2 by screws, the inner wall of the microcomputer 3 is fixedly provided with a stator 5, and a rotor 6 is provided for rotating in the stator 5, and a first rotating shaft 7 is fixedly sleeved on the rotor 6 One side of the microcomputer 3 is fixedly welded with an insulating cover 8, and the top inner wall of the insulating cover 8 is fixedly welded with a brush 9, and one end of the first rotating shaft 7 extends outside the insulating cover 8, and the first rotating shaft in the insulating cover 8 7. The upper fixed sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com