Ultrasonic examination device

A technology of ultrasonic examination and ultrasonic transducer, which is applied in the directions of ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc., which can solve the problem of difficult to achieve accurate puncture , limitations, it is difficult to ensure that the puncture path of the puncture needle is on the scanning plane, etc., to achieve the effect of improving puncture efficiency and accuracy, low trauma, simple and fast surgical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

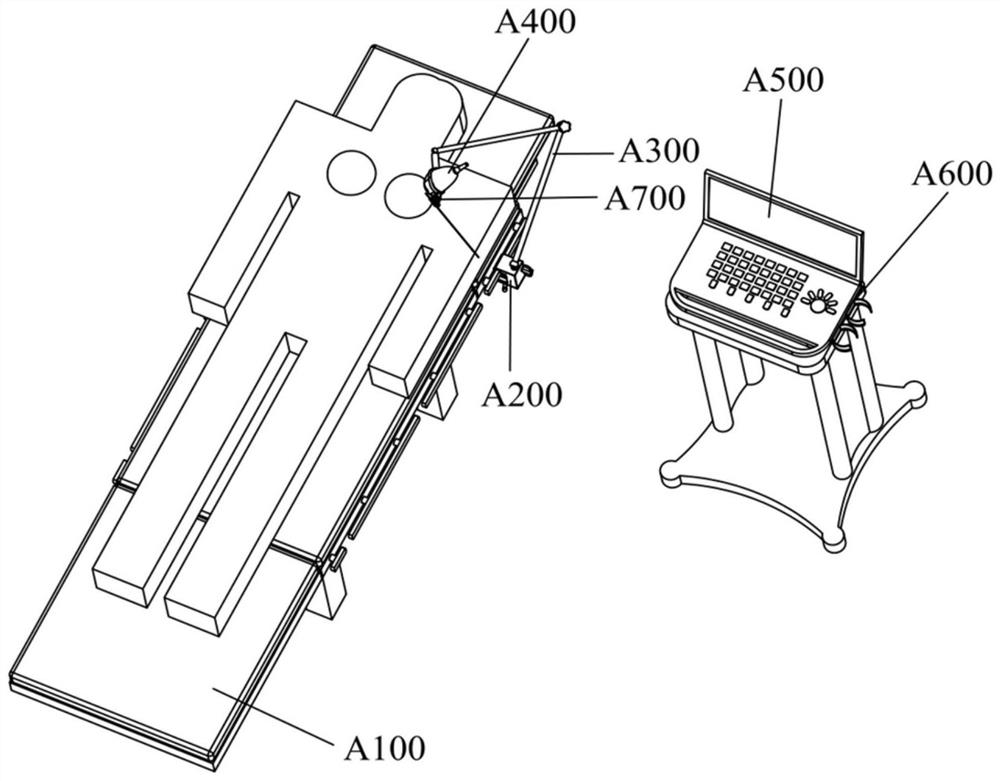

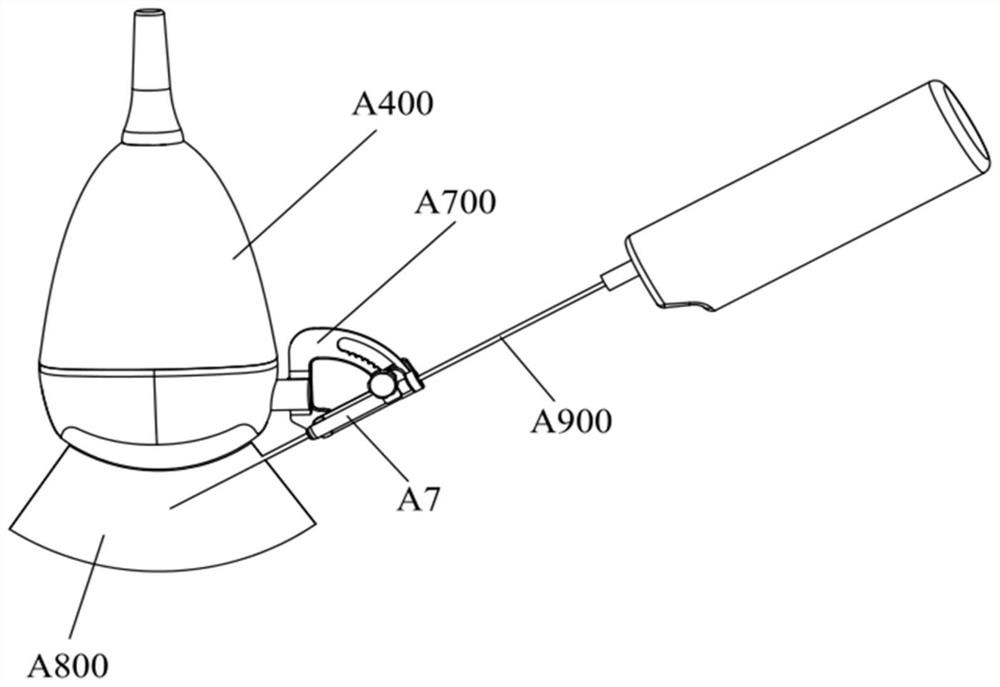

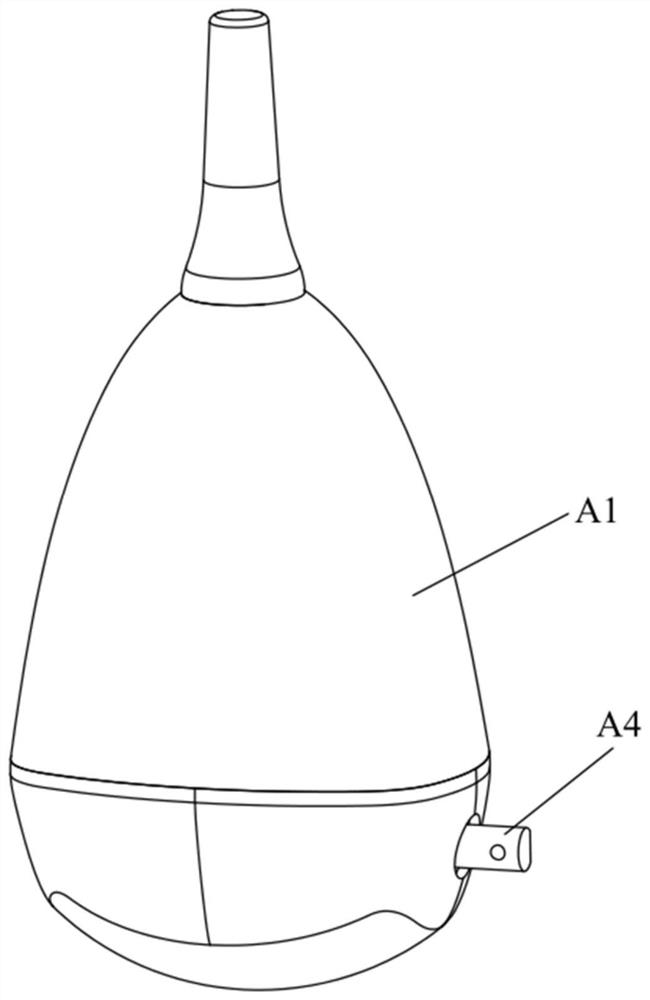

[0088]Such asFigure 1-Figure 6 As shown, this embodiment provides an ultrasonic inspection apparatus, including a 3D ultrasonic probe A400 and a puncture frame A700 installed on the ultrasonic probe A400. The ultrasonic probe A400 includes a mounting shell A1 and an ultrasonic transducer A2 arranged in the mounting shell A1. The ultrasonic transducer A2 is spaced apart from the inner wall of the mounting shell A1. The ultrasonic transducer A2 can be rotated in the mounting shell A1 to scan the relevant parts to be inspected. The puncture frame A700 is arranged outside the mounting shell A1. The puncture frame A700 is provided with a puncture guide hole A721 through which the puncture needle A900 passes. After the ultrasound transducer A2 finds the lesion, the puncture needle A900 is inserted into the lesion to obtain living tissue.

[0089]The ultrasonic inspection device also includes an operating table A100 and a driving mechanism arranged on the operating table A100. The patient lie...

Embodiment 2

[0106]The difference between this embodiment and the first embodiment is:

[0107]SeePicture 9 withPicture 10 As shown, the ultrasonic inspection apparatus of this embodiment further includes a second driving member A8 and a second transmission mechanism A9. The second driving member A8 is arranged in the mounting shell A1, and the output end of the second driving member A8 is connected to the second transmission mechanism A9. The second transmission mechanism A9 is connected with a second main shaft A10, and the second main shaft A10 extends out of the escape hole on the mounting shell A1 and is connected with the puncture frame A700. The second driving member A8 is preferably a motor.

[0108]At the same time, the outputs of the second driving part A8 and the first driving part A3 are controlled, so that the puncture frame A700 and the ultrasonic transducer A2 are controlled to rotate synchronously. When the puncture needle A900 is bent out of the image plane and the puncture needle A90...

Embodiment 3

[0113]The difference between this embodiment and the first embodiment is:

[0114]SeePicture 11 withPicture 12 As shown, in the ultrasonic inspection apparatus of this embodiment, the mounting shell A1 is elongated. The mounting shell A1 includes a probe end shell A11 and a shell A12 that are connected. The probe end shell A11 includes a head and an acoustically transparent hollow rod. The head is sealed at one end of the sound-transmitting hollow rod. The shell A12 communicates with the other end of the sound-transmitting hollow rod. The ultrasonic transducer A2 and the first spindle A4 are both arranged in the sound-transmitting hollow rod. The first driving member A3 is arranged in the housing A12. An escape hole is provided on the sound-transmitting hollow rod. The first main shaft A4 protrudes out of the sound-permeable hollow rod from the avoiding hole through the connecting piece, and is connected with the puncture frame A700. In this embodiment, the connecting piece is a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com