Cyclone type environment-friendly dust removal equipment convenient for dust removal

A kind of dust removal equipment and cyclone technology, which is applied in the field of cyclone environmental protection dust removal equipment, can solve the problems of easy blockage of the discharge port, dust cannot be effectively discharged, and pressure loss is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

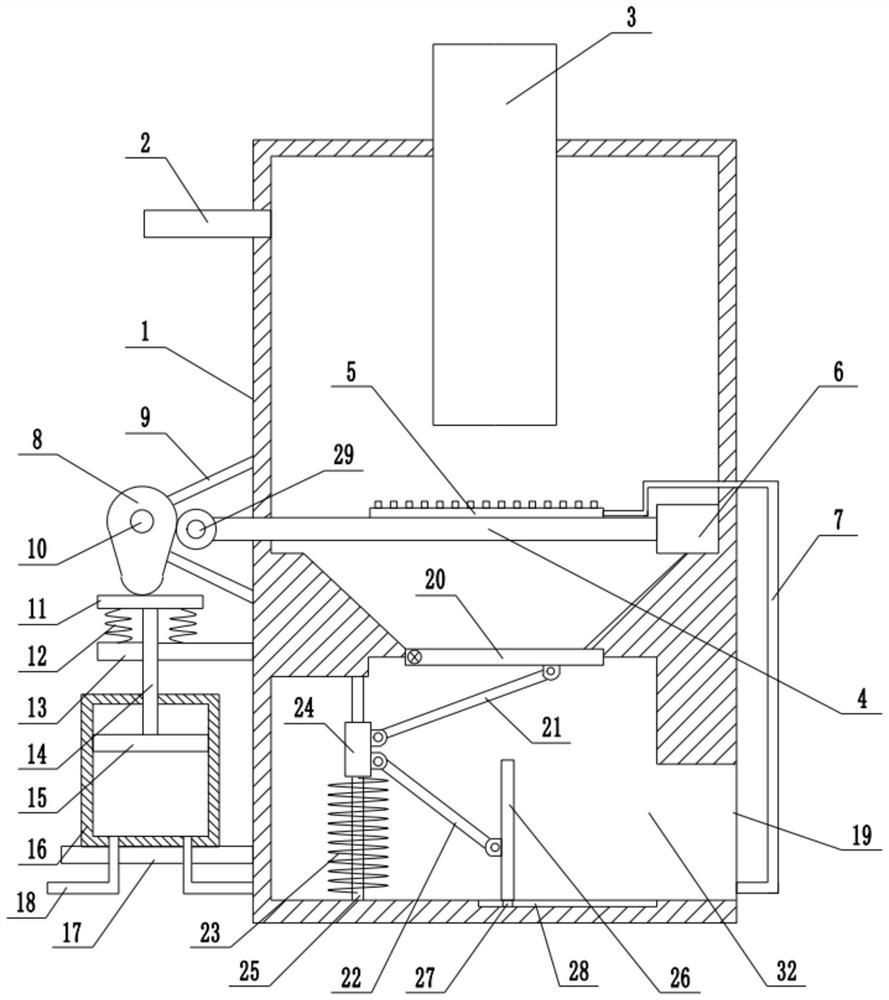

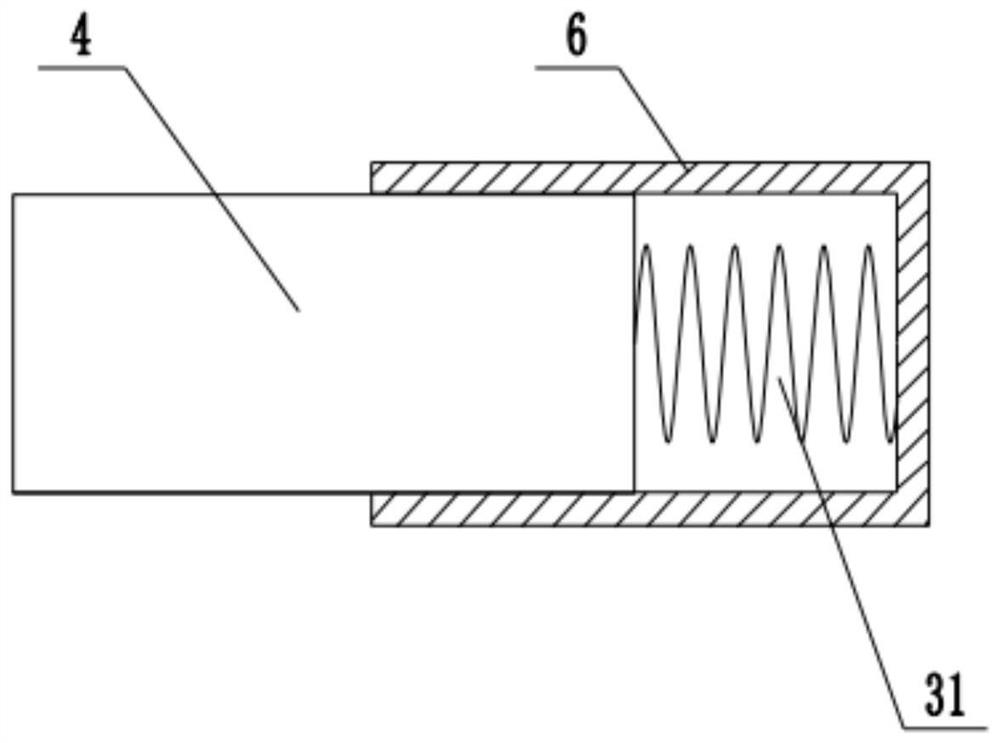

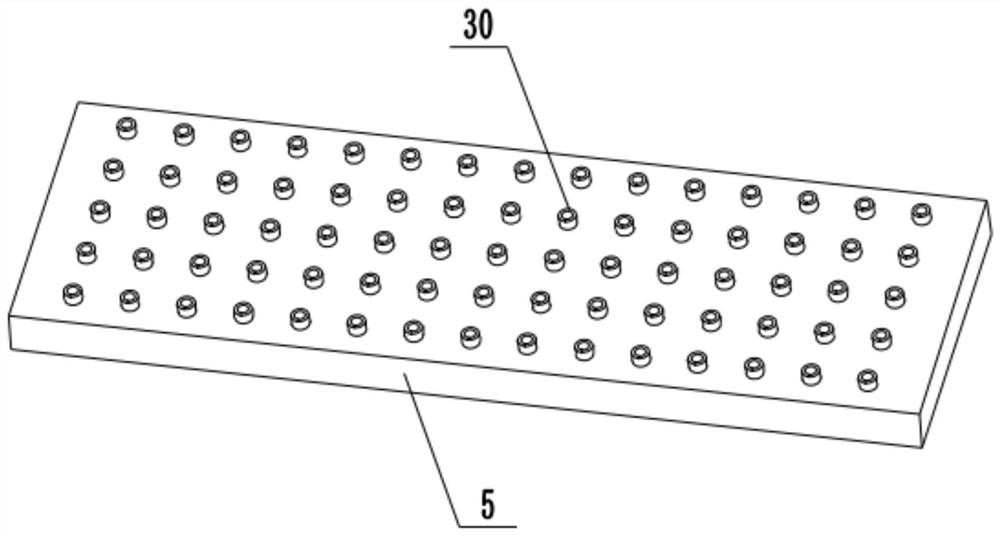

[0028] refer to Figure 1~3 , in the embodiment of the present invention, a cyclone-type environment-friendly dedusting equipment convenient for dust removal includes a dust removal box 1, and a dust removal pipe 3 is installed on the top inside of the dust removal box 1 to realize the discharge of smoke after dust removal, and the inner wall of the dust removal box 1 The upper end is installed with a dust inlet pipe 2, the air intake direction of the dust removal pipe 2 is tangent to the inner wall of the dust removal box 1, and then 2 meets the needs of cyclone dust removal. The dust outlet 19 is installed at the right end, and is used for discharging the dust after the cyclone spraying, and the guide rod 25 is installed on the vertical direction inside the dust discharge chamber 32, and the guide rod 25 middle part is slidably provided with a guide sleeve 24, and the guide sleeve 24 and The guide rod 25 outer cover between the bottom of the inner wall of the dust removal bo...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the middle part of the piston rod 14 is slidably provided with a limit frame 13, and the limit frame 13 is fixed on the outer wall of the dust removal box 1, and a limit frame is set. The frame 13 is used to limit the up and down movement of the piston rod 14 to prevent it from shaking.

[0031]In the present invention, when working, the drive motor is started, and at the same time, the dust inlet pipe 2 introduces the flue gas that needs to be dedusted into the dust removal box 1, and then under the principle of cyclone dust removal, the dedusting effect is realized. During this process, the cam 8 rotates, and its The protruding part continuously contacts the ball 29 and the contact plate 11 for periodic contact, thereby making the piston box 16 work, leading the internal water into the liquid spray chamber 58, and at the same time, the swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com