Integrated device for continuously conveying and loading lighters into trays

A lighter and feeding device technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that do not involve inserting discs into inserting discs for storage and delivery technology, so as to improve processing efficiency and reduce production costs , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

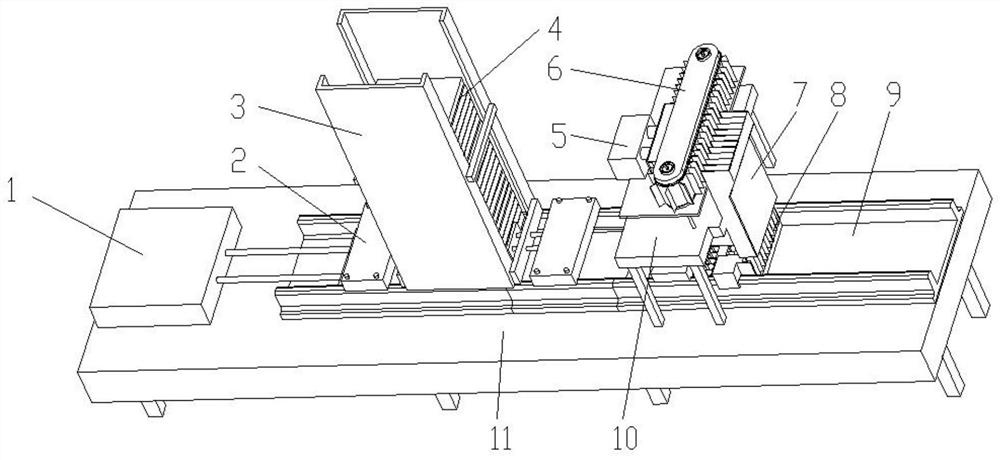

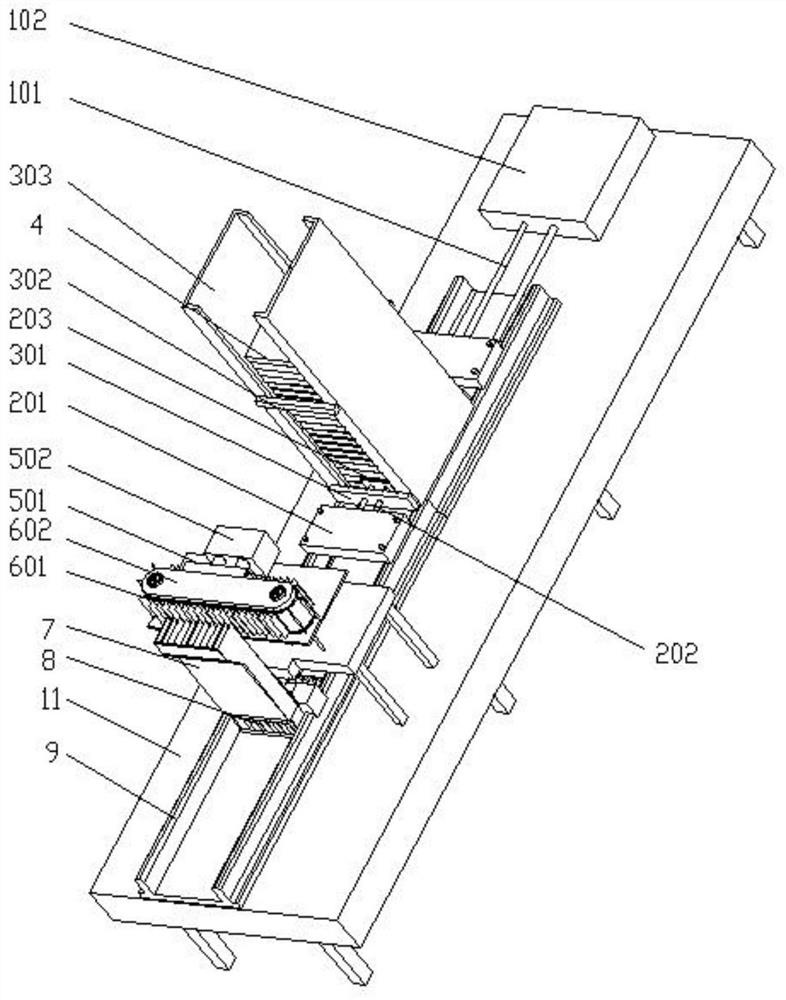

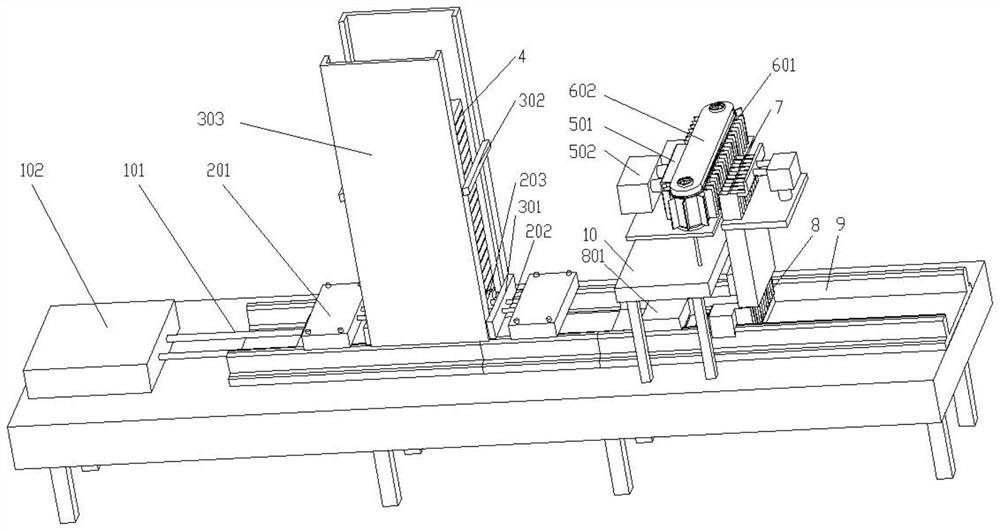

[0038] An integrated device for continuously sending and loading lighters, which is used for inserting lighters into insert trays 4 in batches, and is characterized in that it includes a push tray device 1, a tray storage device 3 for placing insert trays 4, and a tray for clamping The chucking device 2, the pushing device 5, the feeding device 6, the inserting device 7, the whole disc device 8, the guide groove 9 for guiding the inserting disc 4, the second installation Frame 10 and first mounting frame 11; guide groove 9 and second mounting frame 10 are arranged on the first mounting frame 11, push disk device 1, disk storage device 3, whole disk device 8 are arranged in sequence along the direction of guide groove 9, storage The disk device 3 and the whole disk device 8 are erected on the top of the guide groove 9; the chuck device 2 is erected on the top of the guide groove 9 and arranged in cooperation with the disk storage device 3; the disk insertion device 7, the feedin...

Embodiment 2

[0048] An integrated device for continuously sending and loading lighters, which is used for inserting lighters into insert trays 4 in batches, and is characterized in that it includes a push tray device 1, a tray storage device 3 for placing insert trays 4, and a tray for clamping The chucking device 2, the pushing device 5, the feeding device 6, the inserting device 7, the whole disc device 8, the guide groove 9 for guiding the inserting disc 4, the second installation Frame 10 and first mounting frame 11; guide groove 9 and second mounting frame 10 are arranged on the first mounting frame 11, push disk device 1, disk storage device 3, whole disk device 8 are arranged in sequence along the direction of guide groove 9, storage The disk device 3 and the whole disk device 8 are erected on the top of the guide groove 9; the chuck device 2 is erected on the top of the guide groove 9 and arranged in cooperation with the disk storage device 3; the disk insertion device 7, the feedin...

Embodiment 3

[0059] An integrated device for continuously sending and loading lighters, which is used for inserting lighters into insert trays 4 in batches, and is characterized in that it includes a push tray device 1, a tray storage device 3 for placing insert trays 4, and a tray for clamping The chucking device 2, the pushing device 5, the feeding device 6, the inserting device 7, the whole disc device 8, the guide groove 9 for guiding the inserting disc 4, the second installation Frame 10 and first mounting frame 11; guide groove 9 and second mounting frame 10 are arranged on the first mounting frame 11, push disk device 1, disk storage device 3, whole disk device 8 are arranged in sequence along the direction of guide groove 9, storage The disk device 3 and the whole disk device 8 are erected on the top of the guide groove 9; the chuck device 2 is erected on the top of the guide groove 9 and arranged in cooperation with the disk storage device 3; the disk insertion device 7, the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com