Active control device for blade tip clearance of axial flow gas turbine

A technology of active control and blade tip clearance, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem that the compressor cannot be dynamically controlled, and achieve the effects of simple processing, increased blade tip clearance, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

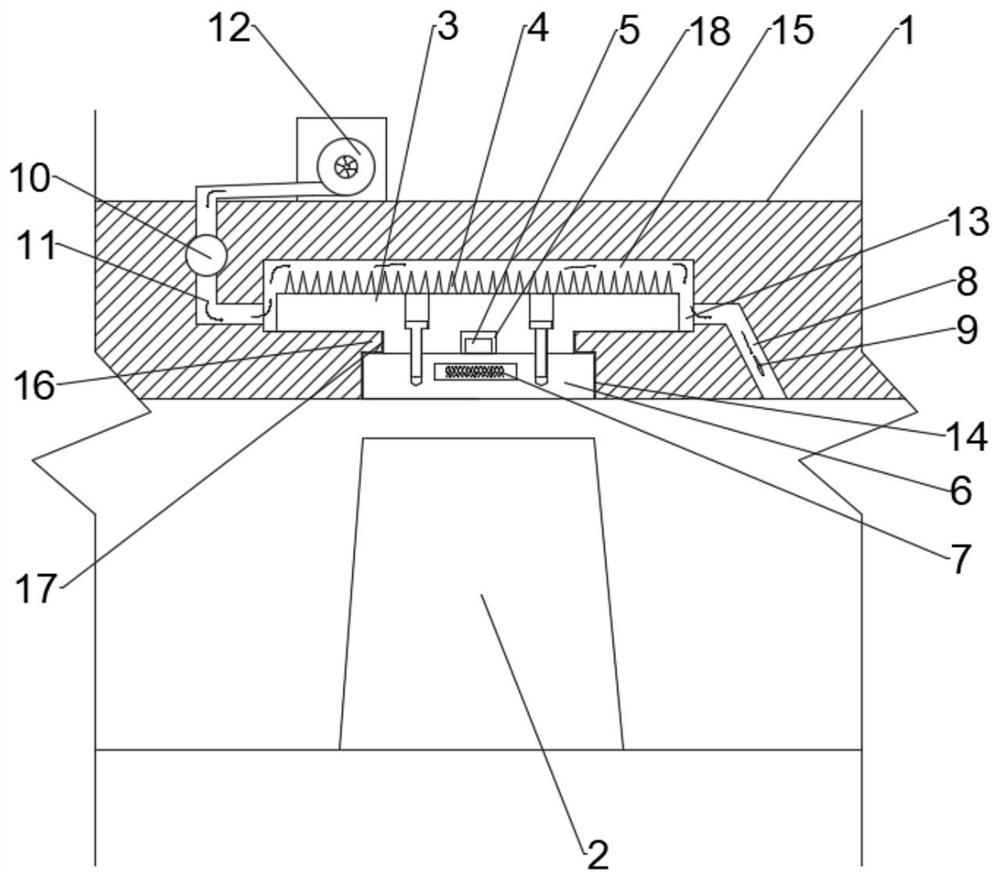

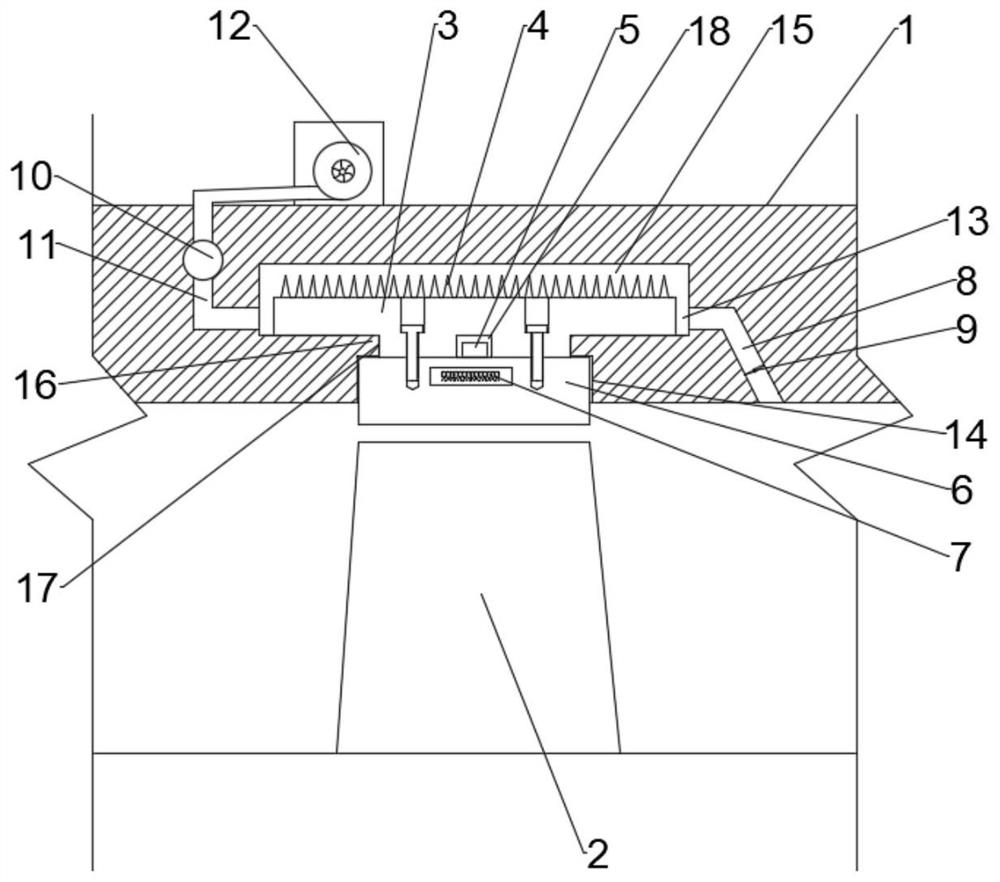

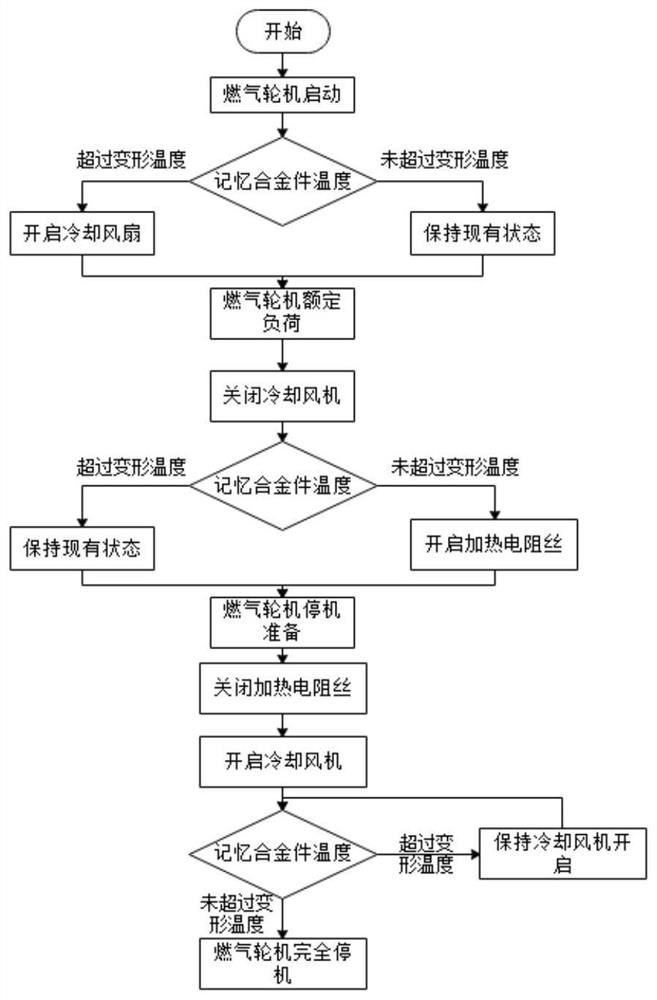

[0026] combine Figure 1-2 As shown, an active control device for blade tip clearance of an axial flow gas turbine includes a compressor cylinder 1, a memory alloy mechanism, a compressor motor blade 2 and an active control mechanism.

[0027] The compressor cylinder 1 is coaxially arranged with the compressor motor blade 21, and the inner wall surface of the compressor cylinder is provided with grooves along the circumference of the inner wall; the grooves include a first groove portion 13 and a second groove portion 14, the The first groove part 13 communicates with the second groove part 14, and the width of the first groove part 13 is greater than the width of the second groove part 14, and the connecting position of the first groove part 13 and the second groove part 14 A limiting boss 16 is provided.

[0028] In this embodiment, the memory alloy mechanism is in the shape of a ring, and the surface of the ring structure with the largest diameter is designated as the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com