Modular combined valve base frame and valve

A modular, valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem of single function of high-pressure valve, can not be replaced without cutting the pipeline, etc., to save maintenance costs, reduce system optimization and upgrade costs, reduce The effect of inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Cooperating with manual shut-off valve and electric shut-off valve:

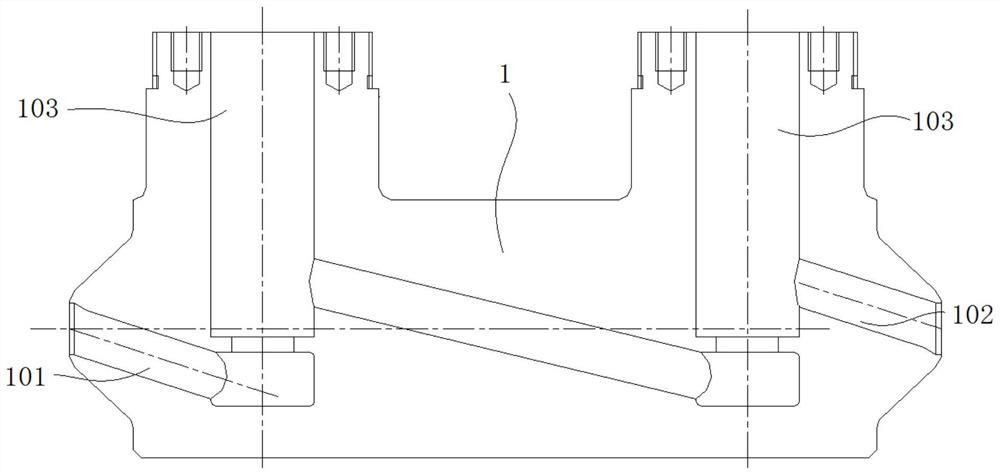

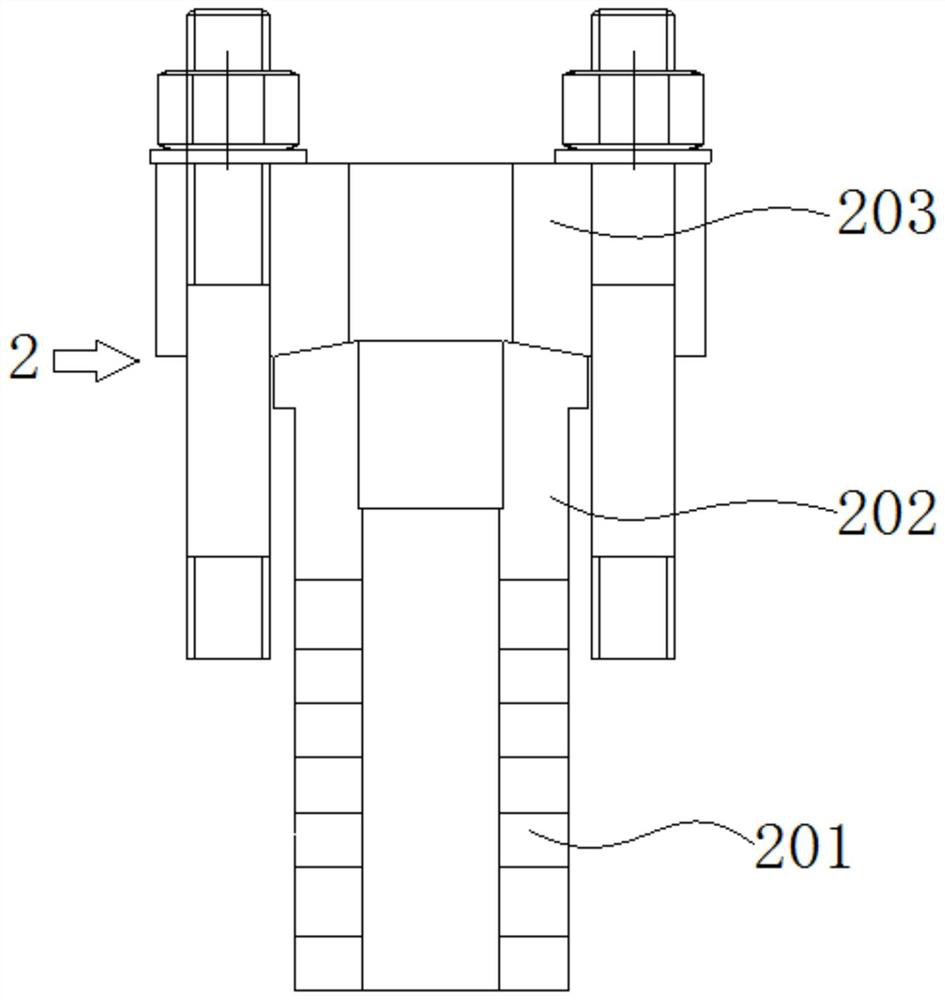

[0038] like Figure 5 As shown, two communicating accommodation grooves 103 are set on the valve body 1, the first passage 101 communicates with the bottom of one accommodation groove 103, the second passage 102 communicates with the side wall of the other accommodation groove 103, and the accommodation groove 103 on the valve body 1 covers It is located outside the packing 201, the packing gland 202 is pressed and set on the upper end of the packing 201, the pressure plate 203 is fastened and set on the upper part of the packing gland 202, the pressure plate 203 is detachably installed on the valve body 1 through bolts, and the stop valve spool is worn on the The center position of the pressure plate 203, the packing gland 202 and the packing 201. The valve core of the stop valve includes a valve seat, a gland, a valve stem and a key. The rod is slidably connected to the pressure sleeve, and the pre...

Embodiment 2

[0040] Cooperate with manual stop valve and electric throttle valve:

[0041] like Image 6 As shown, the installation of the manual shut-off valve is the same as that in Embodiment 1. In another accommodation groove 103, the accommodation groove 103 is sleeved on the outside of the packing 201, the packing gland 202 is pressed on the upper end of the packing 201, and the pressure plate 203 is fastened on the packing. On the upper part of the pressure sleeve 202, the pressure plate 203 is detachably installed on the valve body 1 through bolts. The throttle valve core is set at the center of the pressure plate 203, the packing pressure sleeve 202 and the packing 201. The throttle valve core includes a valve seat, a pressure sleeve , the key and the bottom are valve stems with a conical structure, the valve seat is arranged at the bottom of the accommodation groove 103, the valve stem is slidingly connected with the pressure sleeve, and the pressure sleeve is provided with evenl...

Embodiment 3

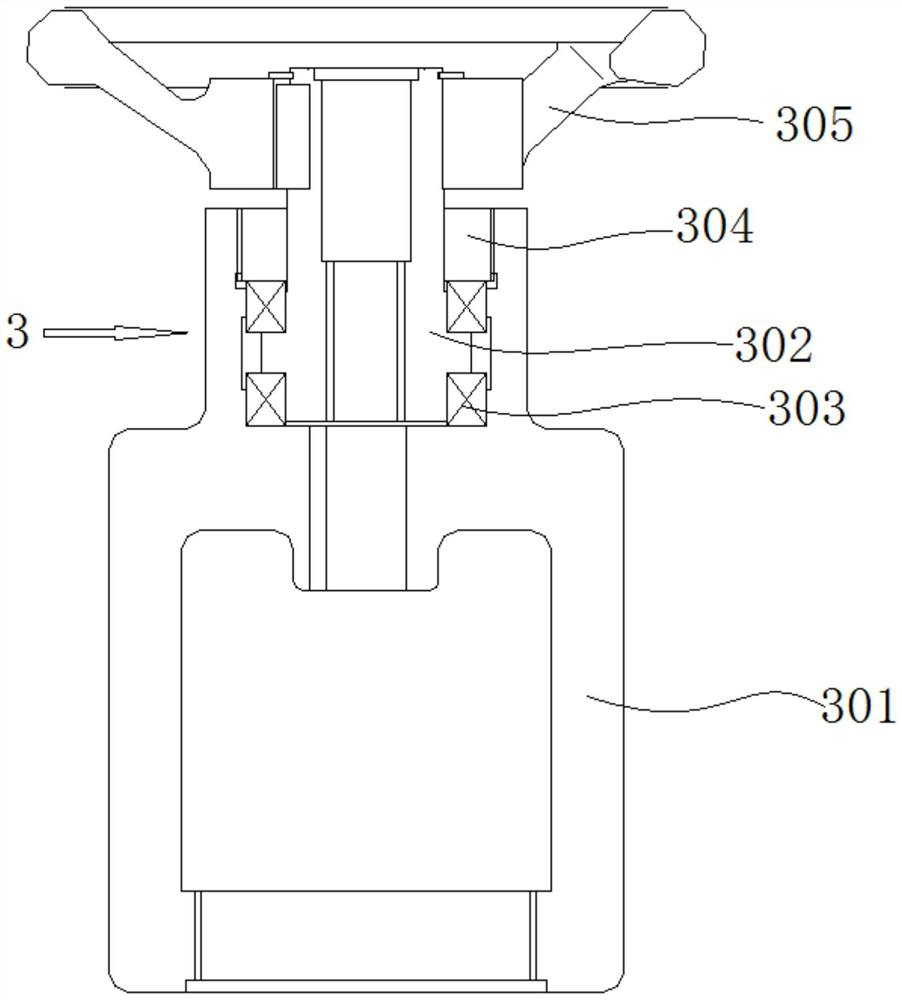

[0043] Cooperate with manual shut-off valve and electric regulating valve

[0044] like Figure 7 As shown, the installation of the manual shut-off valve is the same as that in Embodiment 1. In another accommodation groove 103, the accommodation groove 103 is sleeved on the outside of the packing 201, the packing gland 202 is pressed on the upper end of the packing 201, and the pressure plate 203 is fastened on the packing. On the upper part of the pressure sleeve 202, the pressure plate 203 is detachably installed on the valve body 1 through bolts. The regulating valve spool is set at the center of the pressure plate 203, the packing pressure sleeve 202 and the packing 201. The regulating valve spool includes a valve seat, a pressure sleeve, and a key. And the valve stem, the valve seat and the pressure sleeve are all provided with uniformly distributed holes, the valve seat is arranged at the bottom of the accommodation groove 103, the pressure sleeve is set at the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com