Kneading equipment for processing dough with high content of coarse cereals

A high content, dough technology, which is applied in the direction of dough processing, dough mixer, horizontal installation tool mixing/kneading, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of uniform kneading, easy operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

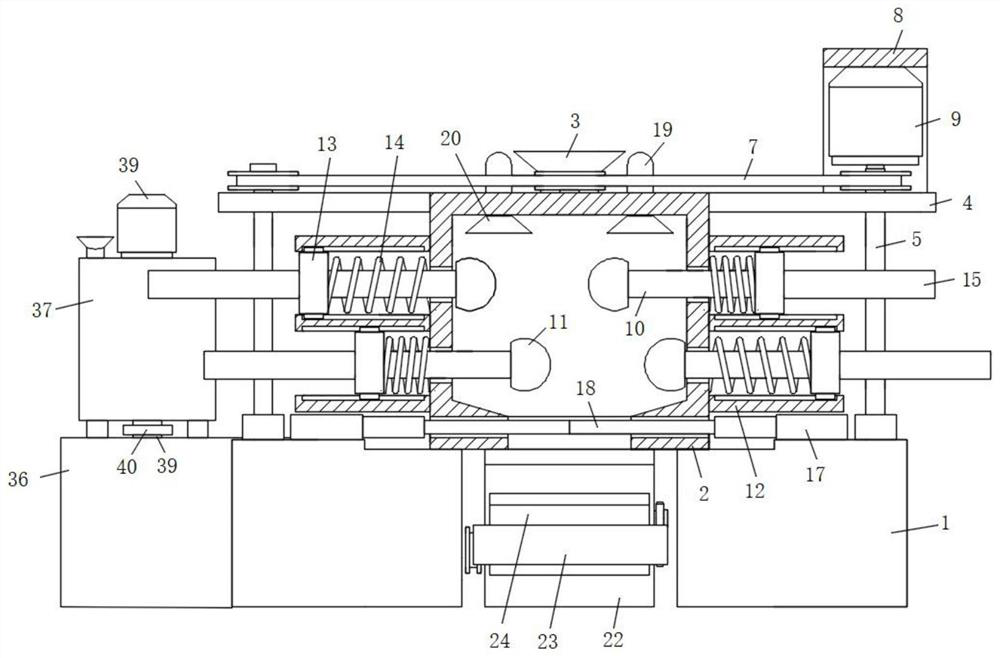

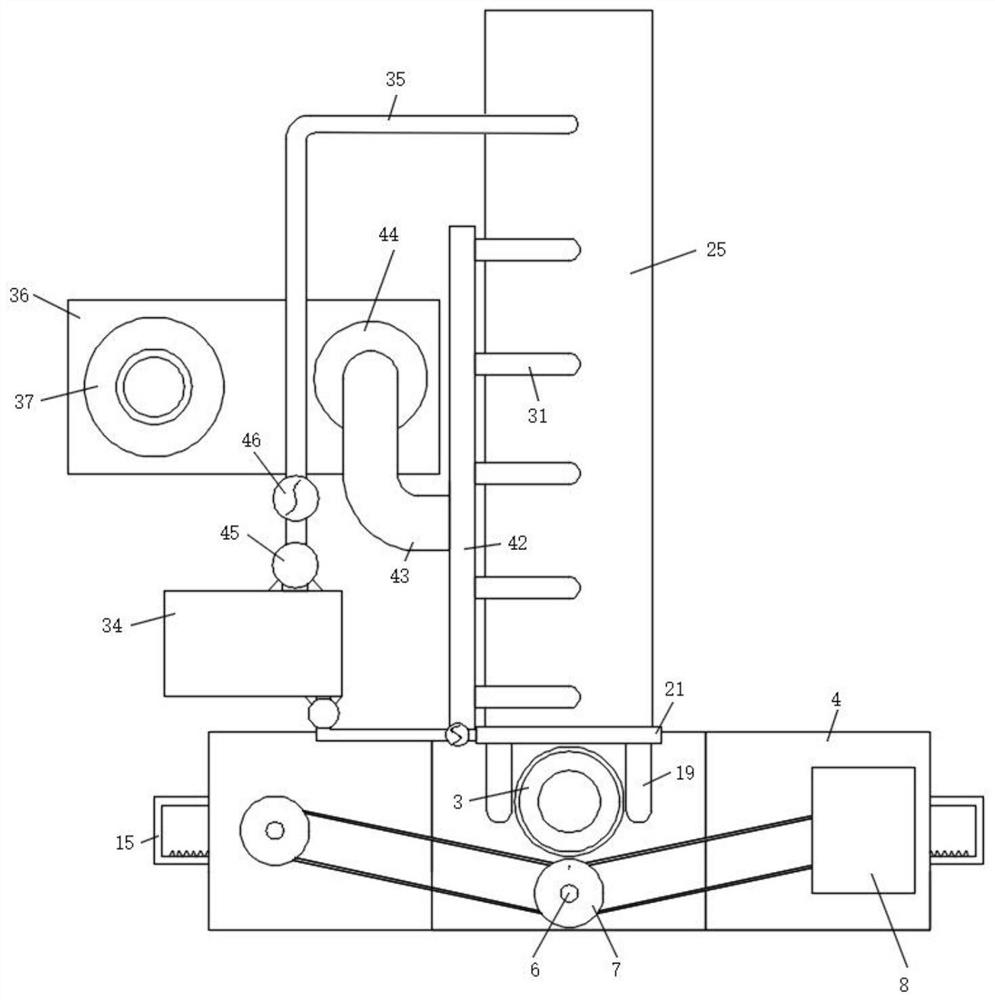

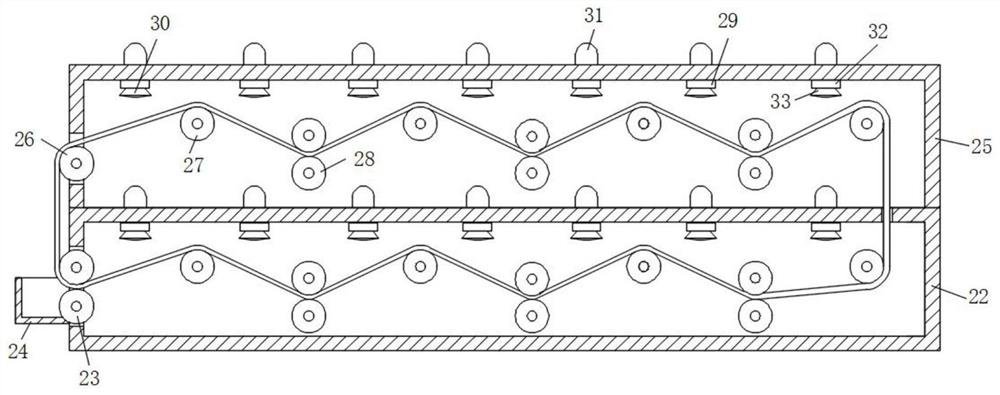

[0030] refer to Figure 1-5, a kneading equipment for dough processing with high miscellaneous grain content, comprising a fixed seat 1, two fixed seats 1 are arranged and symmetrically fixed on the working surface, the tops of the two fixed seats 1 are fixedly connected with a kneading barrel 2 by screws, The top surface of the kneading barrel 2 is connected with a feeding funnel 3, and both sides of the top of the kneading barrel 2 are welded with a horizontal plate 4, and the end of the horizontal plate 4 facing away from the kneading barrel 2 is rotatably connected to the fixed seat 1 with a rotating rod 5 , the middle part of the front side of the kneading barrel 2 top is also rotatably connected with a fixed rod 6, and the upper ends of the rotating rod 5 pass through the horizontal plate 4 and are rotatably connected with the fixed rod 6 through the conveyor belt 7, and the top surface of one side of the horizontal plate 4 is also fixed with an installation Frame 8, the...

Embodiment 2

[0033] Such as figure 1 with 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two pressure rods 10 are arranged symmetrically on the upper and lower sides of the two side walls of the kneading barrel 2, and two driving gears 16 are arranged on both sides of the kneading barrel. Placed in the rectangular frame 15, and the initial positions of the two pressure rods 10 on the same side are set alternately.

[0034] In this embodiment, two pressing rods 10 are alternately arranged on the two side walls of the kneading barrel 2, so as to realize the intermittent impact of the dough, thereby ensuring the pressing quality of the dough well.

Embodiment 3

[0036] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the two ends of the return spring 14 are respectively fixed on the push block 13 and the side wall of the kneading barrel 2 .

[0037] In this embodiment, by fixing the two ends of the spring 14 on the push block 13 and the side wall of the kneading barrel 2 respectively, the movement of the pressing rod 10 is made more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com