Multi-angle paint spraying workbench for novel wall plate production

A sheet production and workbench technology, which is applied in spray booths, spray devices, and devices for applying liquid to surfaces, etc., can solve problems such as the inability of spray painting workbenches to spray paint from multiple angles, and the single function of the workbench, which can eliminate the need for intermediate The effect of transportation process, improving overall comfort and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

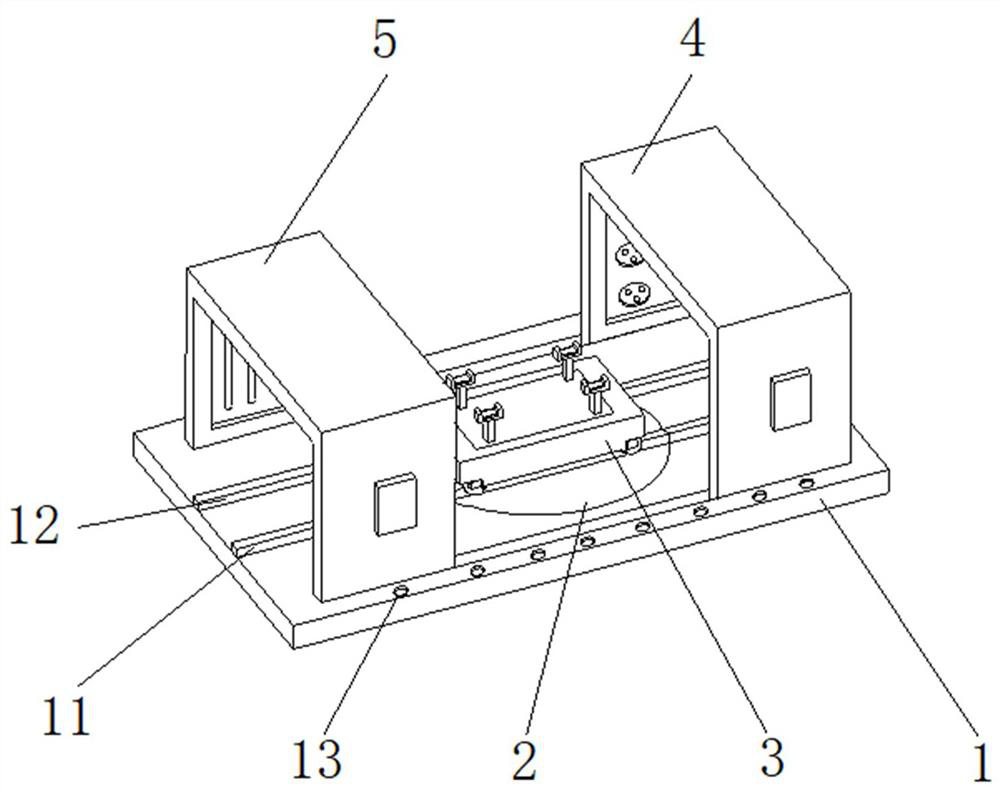

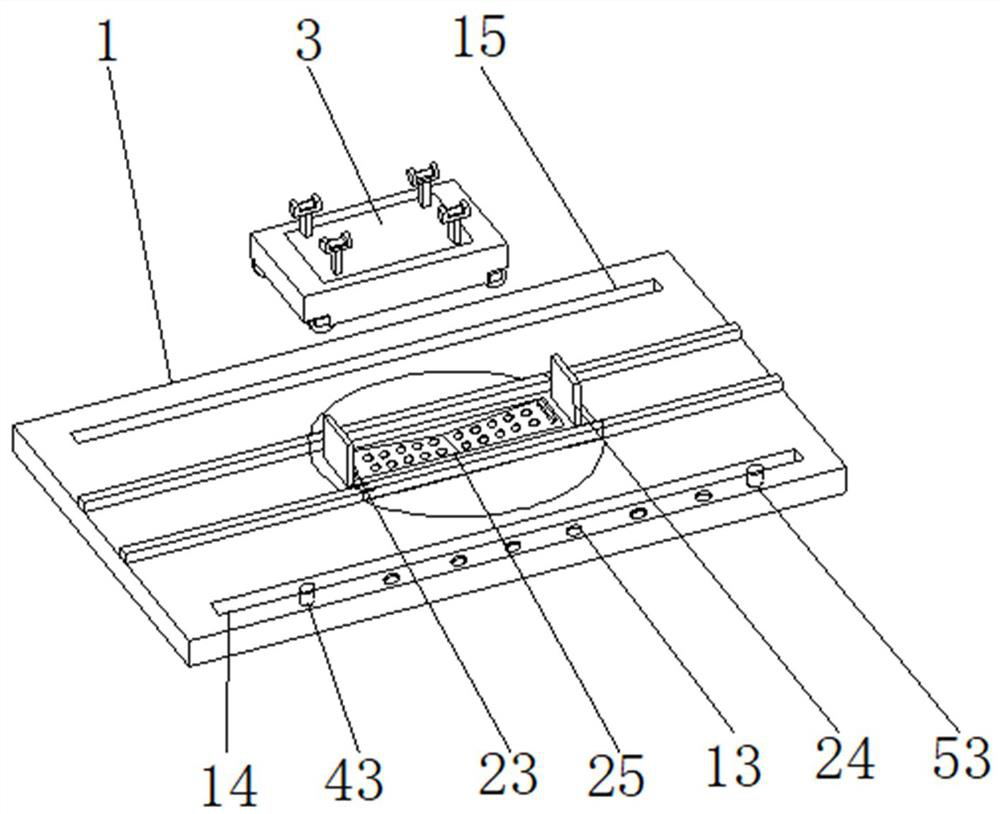

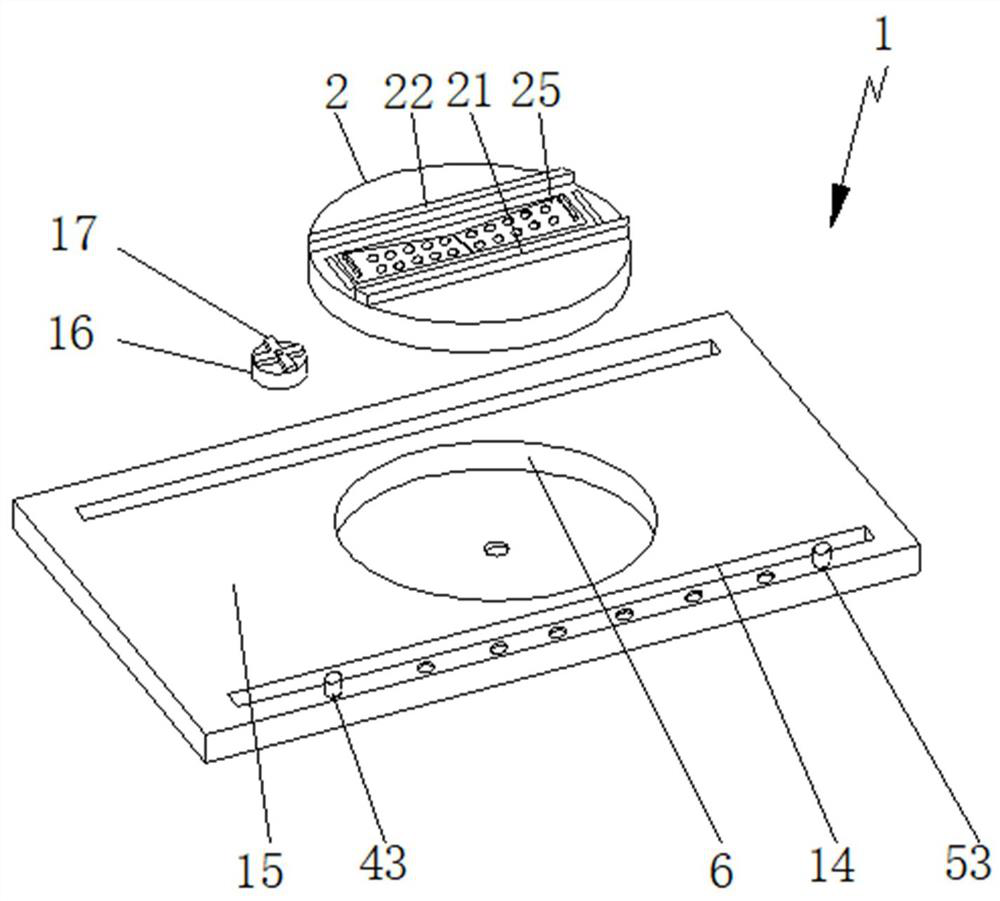

[0037] see Figure 1-9 As shown, a new type of multi-angle painting workbench for the production of wall panels includes a workbench 1, a turntable groove 6 is provided at the top center of the workbench 1, and a rotating motor is provided through the bottom center of the turntable groove 6. The top of the rotating motor is fixedly provided with a motor shaft 16, and the top of the motor shaft 16 is fixedly provided with a cross projection 17, and the top of the cross projection 17 is movably connected with a turntable 2, and the top of the turntable 2 is movably connected with a flatbed car 3, and the top of the flatbed cart 3 There is a rectangular groove, and a lifting block 31 is installed inside the rectangular groove. The two sides of the top of the workbench 1 are respectively provided with a first chute 14 and a second chute 15, and the inside of the first chute 14 is slidingly connected. There is a painting assembly 4, and the inside of the second chute 15 is slidably...

Embodiment 2

[0044] see Figure 1-9 As shown, a new type of multi-angle painting workbench for the production of wall panels includes a workbench 1, a turntable groove 6 is provided at the top center of the workbench 1, and a rotating motor is provided through the bottom center of the turntable groove 6. The top of the rotating motor is fixedly provided with a motor shaft 16, and the top of the motor shaft 16 is fixedly provided with a cross projection 17, and the top of the cross projection 17 is movably connected with a turntable 2, and the top of the turntable 2 is movably connected with a flatbed car 3, and the top of the flatbed cart 3 There is a rectangular groove, and a lifting block 31 is installed inside the rectangular groove. The two sides of the top of the workbench 1 are respectively provided with a first chute 14 and a second chute 15, and the inside of the first chute 14 is slidingly connected. There is a painting assembly 4 , and a drying assembly 5 is slidably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com