Welding method for butt joint of T2 red copper and S32168 stainless steel pipes

A stainless steel tube and welding method technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of reduced mechanical properties of welded joints, large differences in physical properties, and high welding difficulty, and achieve efficient connection, moderate melting point, and guaranteed resistance. Effects of Corrosive Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] For ease of understanding, the specific working method of the present invention is further described as follows here:

[0044] In the welding method of the present invention, T2 copper tubes and S32168 stainless steel tubes can be selected for specific welding. in:

[0045] The chemical composition of the T2 copper tube base material is: 99.9% Cu+Ag, Fe, S, and Pb are not more than 0.005%; the melting point of the T2 copper tube is 1065-1082.5°C, and the thermal conductivity is 380λ / w·(m· k) -1 , the coefficient of linear expansion is 16.92α / 10 -6 k -1 .

[0046]The chemical composition of the base material of S32168 stainless steel pipe is: C content is 0.08%, Cr content is 17-19%, Ni content is 9-12%, Ti content is ≥5C-0.70%; melting point is 1398-1427°C, thermal conductivity 16.1λ / w·(m·k) -1 , the coefficient of linear expansion is 16.0α / 10 -6 k -1 .

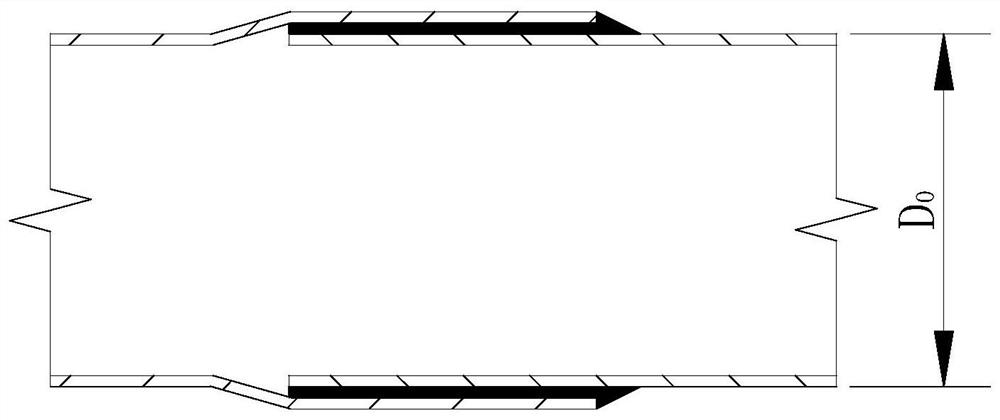

[0047] The welding method is to expand the T2 copper tube first, then assemble it with the S32168 stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com