Sand blasting circulation system

A circulation system and sand blasting technology, which is applied in the field of sand blasting systems, can solve the problems of cost burden, data waste, limited abrasive storage of sand cylinders, and affecting work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

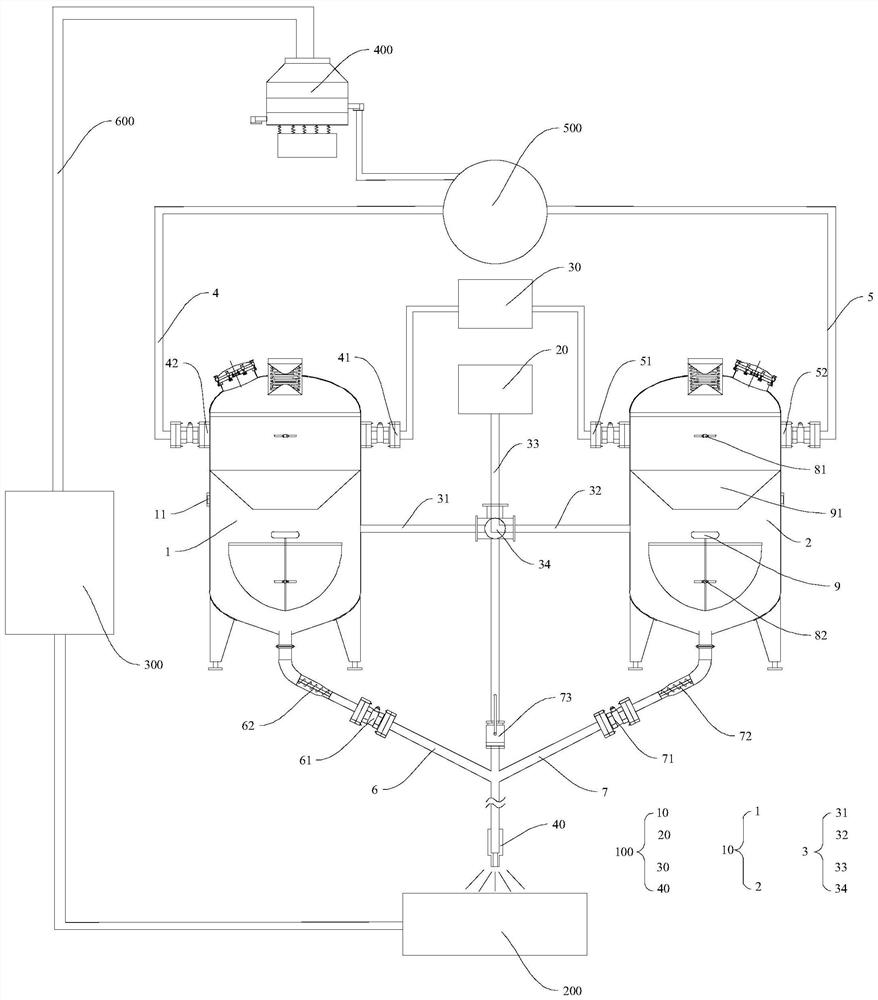

[0024] Sandblasting circulation system of the present invention such as figure 1 As shown, it includes a sandblasting machine 100, a collection tank 200 for collecting used abrasives, a suction machine 300 for suctioning used abrasives, a vibrating screen 400 for filtering impurities in the used abrasives, and Abrasive hopper 500 for collecting processed abrasives, said collecting tank 200 , suction machine 300 , vibrating screen 400 and abrasive hopper 500 are connected through pipeline 600 in sequence. Through the above settings, when sandblasting the workpiece, the workpiece can be placed in the collection tank 200, and then the sandblasting machin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap