Rubber raw material crushing device for data line production

A technology of rubber raw materials and crushing devices, which is applied in the direction of grain processing, etc., can solve the problems of single crushing, poor crushing effect, and different sizes of rubber raw materials, and achieve the goal of increasing the feeding speed, improving the crushing effect, and improving the thoroughness of feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

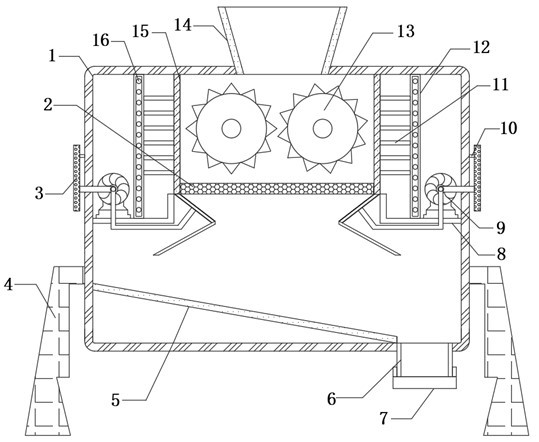

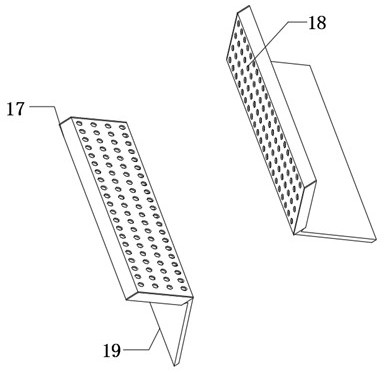

[0027] refer to Figure 1-2 , a rubber raw material crushing device for data line production, comprising a crushing box 1, the inner walls of both sides of the crushing box 1 are fixedly connected with fixing frames 8, and the top outer walls of the two fixing frames 8 are fixedly connected with blowers 9, and the crushing box The inner wall of 1 is fixedly connected with a fixed frame 15, and the interior of the fixed frame 15 is provided with a crushing mechanism 13, the inner wall of the fixed frame 15 near the bottom is fixedly connected with a sieve plate 2, and the outer walls of both sides of the sieve plate 2 are fixedly connected with an air plate 17 , and the opposite side outer walls of the two air plates 17 have air holes 18 at equal distances, the bottom outer walls of the air plates 17 are fixedly connected with the flow limiting plate 19, the blower end of the blower 9 is fixedly connected with an air delivery pipe, and the other side of the air delivery pipe On...

Embodiment 2

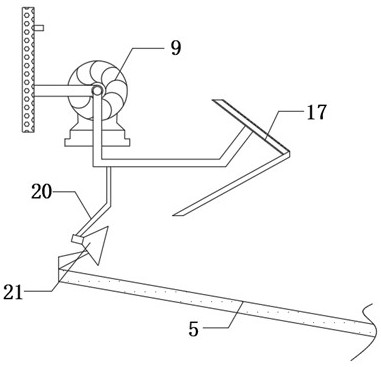

[0036] refer to Figure 1-3 , a rubber raw material crushing device for data line production. Compared with Embodiment 1, the inner wall of the crushing box 1 is fixedly connected with an air nozzle 21, and the inner wall of the gas delivery pipe is fixedly connected with a shunt pipe 20, and the other end of the shunt pipe 20 is fixed. Connected to the inside of the air nozzle 21.

[0037] Working principle: Compared with Example 1, when performing the blanking operation, the wind force of the blower 9 is transmitted from the air nozzle 21 to blow down the raw materials attached to the drainage plate 5, so that the rubber raw materials are quickly discharged through the blanking pipe 6 .

[0038] The beneficial effects of the present invention are:

[0039] 1. When the rubber raw material is crushed, the crushing mechanism crushes the rubber raw material through the installation of a sieve cylinder, blower and air plate. During the crushing process, the blower guides the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com