Purification device for electroplating sewage filtration treatment and operation method of purification device

A purification device and technology for sewage, applied in filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor filtration and purification effect of water body, rapid treatment of unfavorable sewage, and complete precipitation of unfavorable impurities, so as to improve the Purification effect, easy anti-interference filtration, solve the effect of long flocculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

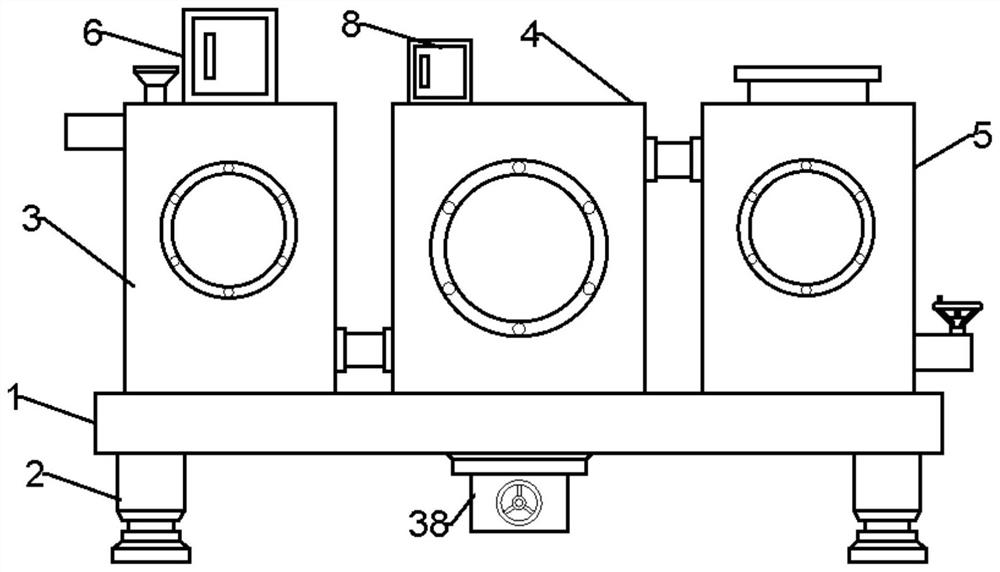

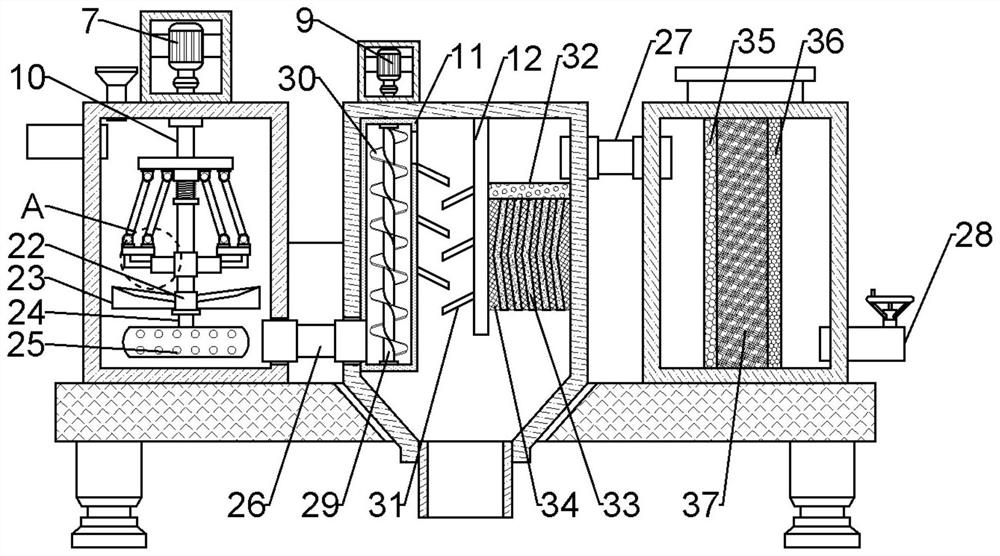

[0035] Embodiment 1: in order to realize the effective treatment of electroplating sewage, see Figure 1-4 , this embodiment provides a purification device for electroplating sewage filtration treatment, specifically, it includes a base 1, the base 1 is a rectangular plate-shaped horizontally arranged, vertical To the supporting legs 2 provided, a rectangular flocculation box 3 is fixedly installed on one side of the top surface of the base 1, and a tapered opening is opened in the middle of the top surface of the base 1, and a rectangular flocculation box 3 is fixedly installed in the rectangular opening. Settling tank 4, and the bottom of the settling tank 4 is conical funnel-shaped; the other side of the top surface of the base 1 is fixedly installed with a clean water tank 5, and a motor box is fixedly installed in the middle of the top surface of the flocculation tank 3 6. A first motor 7 is vertically fixedly installed in the motor box 6, and the model of the first motor...

Embodiment 2

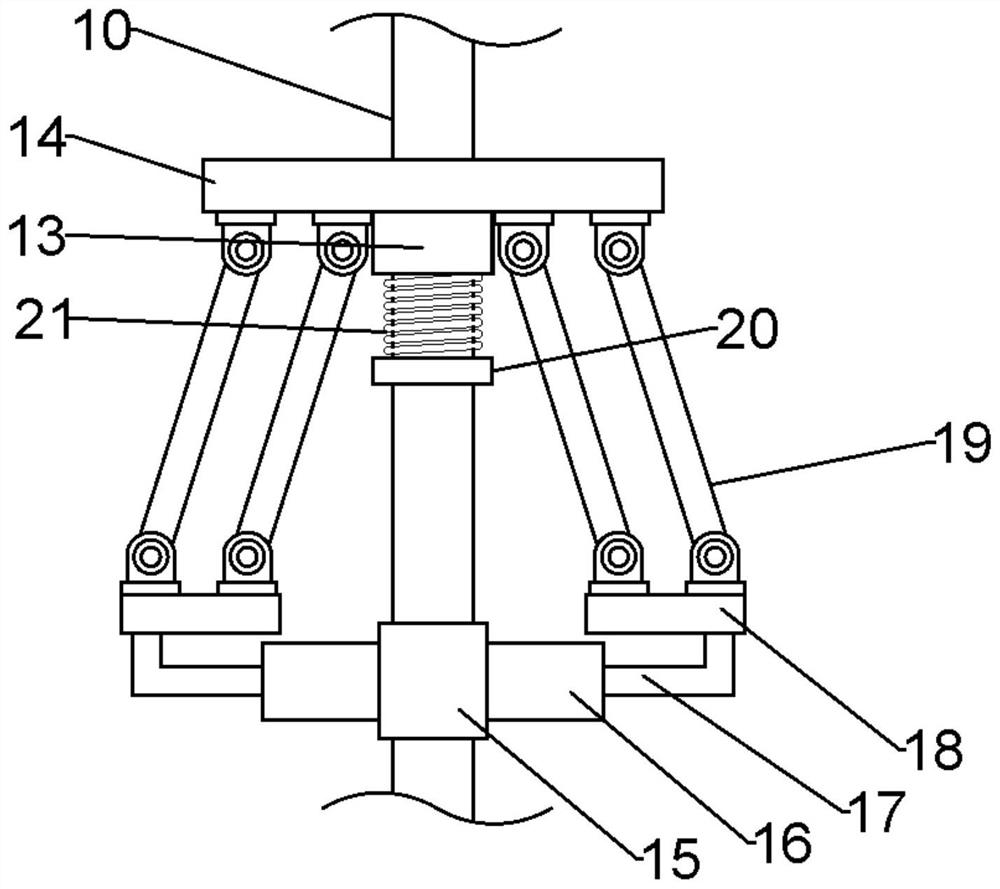

[0040] Embodiment 2: In order to realize the disturbance of the water body in the sedimentation tank, in the present invention, the disturbance assembly includes a third casing 22, a stirring blade 23, a connecting rod 24 and a disturbance plate 25, and the third casing 22 is fixedly sleeved At the bottom end of the rotating rod 10, horizontally arranged stirring blades 23 are fixedly installed on both sides of the pipe body of the third sleeve 22, and a vertically arranged connecting rod is fixedly installed at the bottom end of the rotating rod 10. 24, the bottom end of the connecting rod 24 is fixedly installed with a horizontal disturbance plate 25, and a number of circular spoiler holes are equidistantly opened on the front end face of the disturbance plate 25; between the flocculation box 3 and The bottom between the sedimentation tanks 4 is horizontally provided with a first connecting pipe 26, and the two ends of the first connecting pipe 26 penetrate into the flocculat...

Embodiment 3

[0041] Embodiment 3: for better realizing the actual use of the present invention, refer to Figure 5 , In this embodiment, a method for operating a purification device for electroplating sewage filtration treatment is provided, specifically, including the following steps:

[0042] Step 1: Firstly, the first motor 7 and the second motor 9 are respectively electrically connected to the external power supply through wires, and then the sewage generated by electroplating is injected into the flocculation tank 3 from the water inlet pipe, and then the flocculant is put into the flocculation tank 3 from the dosing pipe. Inside the flocculation box 3;

[0043] Step 2, by controlling the rotation of the first motor 7 to drive the rotation of the rotation rod 10, the rotation of the rotation rod 10 drives the stirring assembly and the disturbance assembly to rotate, and the stirring assembly facilitates the fusion of the electroplating sewage and the flocculant to facilitate the unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com