Centrifugal dehydrator for rapeseed oil refining technology

A centrifugal dehydrator, rapeseed oil technology, applied in the direction of fat oil/fat refining, filtration and separation, separation methods, etc., can solve the problems of centrifuge cylinder hole clogging, affecting oil discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

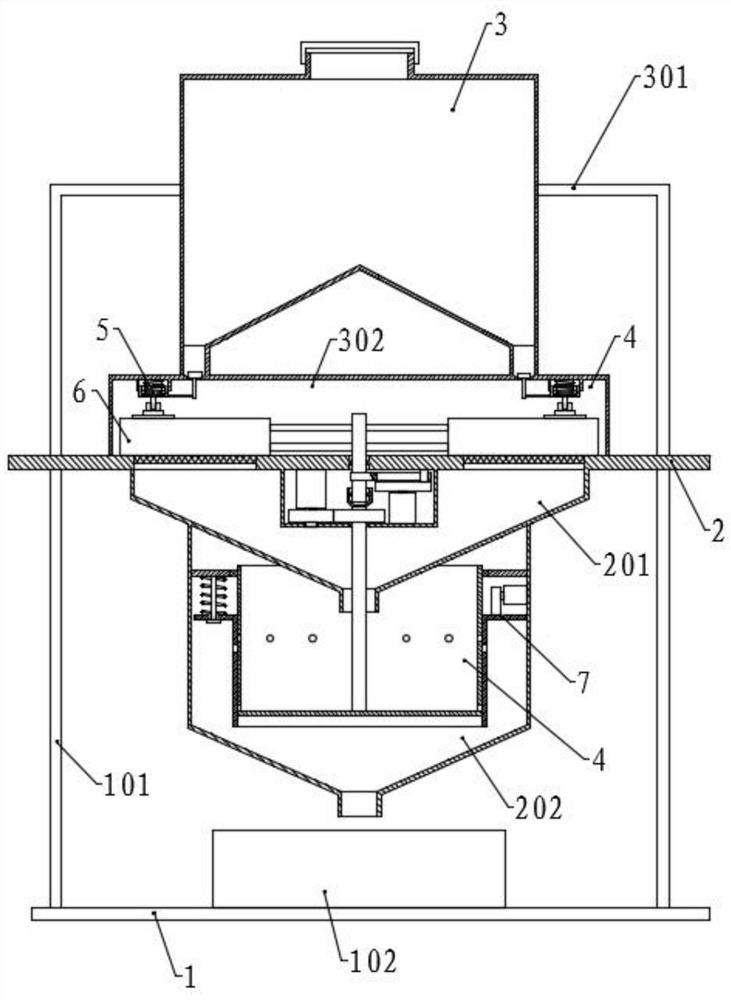

[0050] Please refer to the accompanying drawings, the present invention provides a technical solution: a centrifugal dehydrator for rapeseed oil refining technology, including a base 1, a workbench 2 and a storage box 3, and the workbench 2 is fixed by a first support rod 101 On the top of the base 1, the material storage box 3 is fixed on the top of the workbench 2 through the second support rod 301;

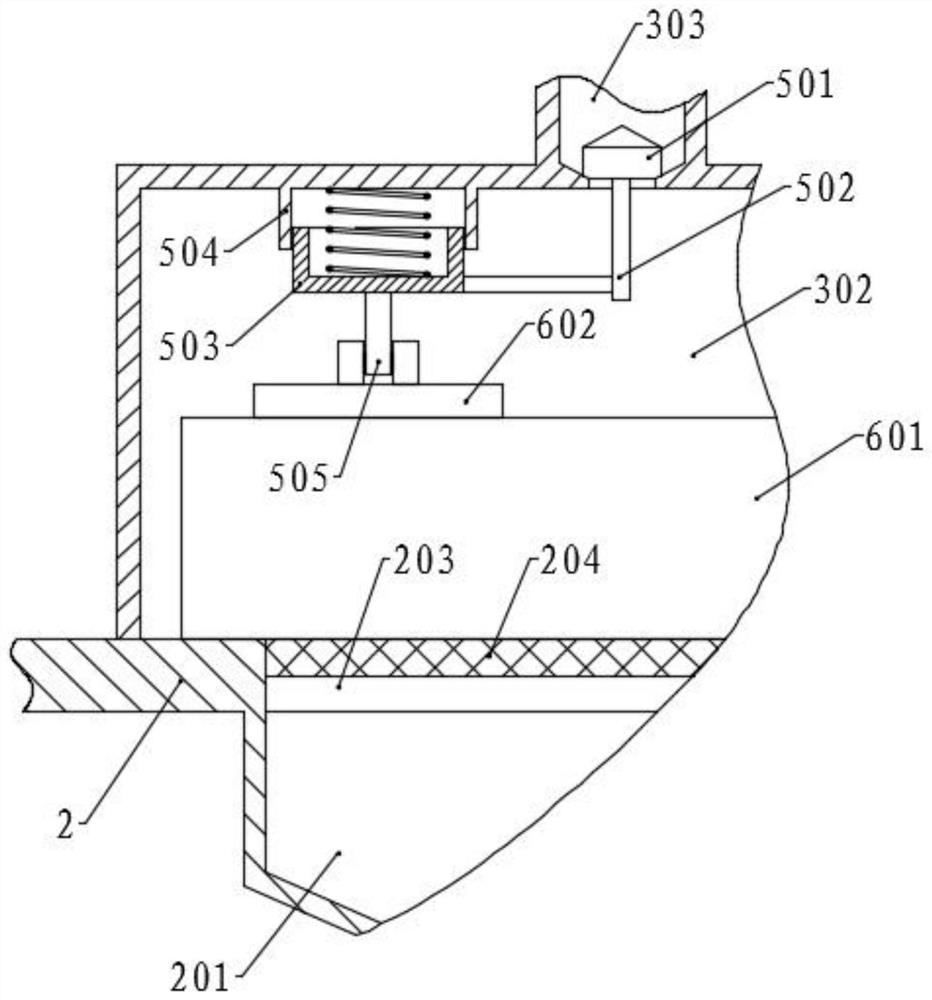

[0051] The top surface of the workbench 2 is provided with an annular groove 203, and an annular filter screen 204 is fixed in the annular groove 203, and a filter box 302 is fixed on the position corresponding to the annular filter screen 204 on the workbench 2, and the bottom of the material storage box 3 is along the circumferential direction. A plurality of feeding pipes 303 are uniformly fixed, and the feeding pipes 303 communicate with the filter box 302, and the position corresponding to each feeding pipe 303 in the filter box 302 is provided with a first sealing assembly...

Embodiment 2

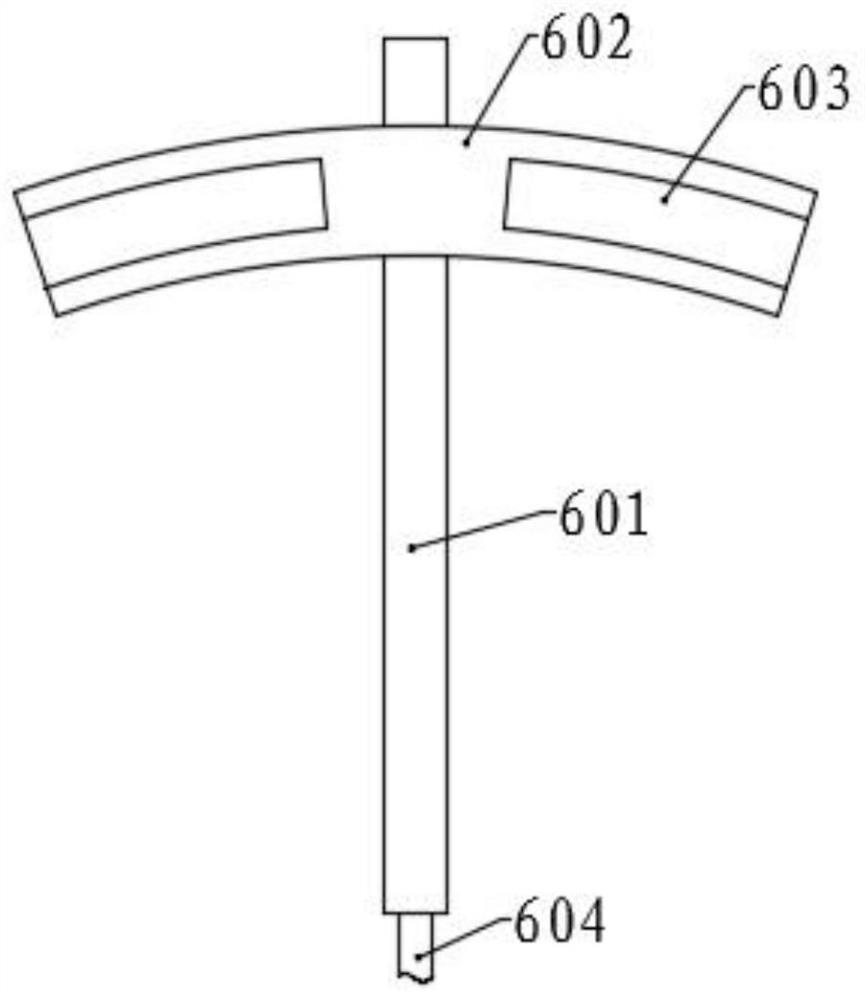

[0054] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the first sealing assembly 5 includes a sealing plug 501 arranged in the feeding tube 303, the top surface of the sealing plug 501 is set as a conical surface, and the outer ring of the bottom surface is set It is a conical surface, and the nozzle of the feeding pipe 303 is correspondingly provided with a conical surface, and the bottom surface of the sealing plug 501 is connected with the conical surface at the nozzle, and the bottom of the sealing plug 501 is fixed with a moving rod 502, and the moving rod 502 The outside of the bottom end of the filter box 503 is fixed with a moving cylinder 503 through a cross bar, and the top surface of the filter box 302 is correspondingly fixed with a fixed cylinder 504. A spring is arranged between the surfaces, and the bottom end of the moving cylinder 503 is fixed with a vertical push rod 505, and the bottom end of the push ro...

Embodiment 3

[0069] The structure of this embodiment is basically the same as that of Embodiment 1, except that a filter press assembly 9 is provided at a position between two adjacent feeding pipes 303 in the filter box 302, and the filter press assembly 9 includes a pressing plate 901, and the pressing plate Both sides of the top surface of 901 are fixed with vertical slide bar 904 symmetrically, the top of slide bar 904 passes through the top surface of filter box 302 and is fixed with spring plate 905, and the top surface of spring plate 905 and filter box 302 is provided with There is a spring, and the top surface of the inner cavity of the filter box 302 is symmetrical to the position in the middle of the pressure plate 901 and is rotationally connected with two intermeshing connecting gears 903, one of which is connected with a motor, and the two connecting gears 903 are fixed with Pressing rod 902, and the two pressing rods 902 are symmetrically inclined, and the bottom end of press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com