Wet lease rod structure for slasher wet lease layering device

A layering device and wet splitting technology, which is applied in the field of textile processing, can solve the problems of slurry agglomeration, unfavorable wet strand splitting operation, and affecting splitting processing, so as to achieve accurate splitting processing, improve splitting efficiency, The effect of preventing caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

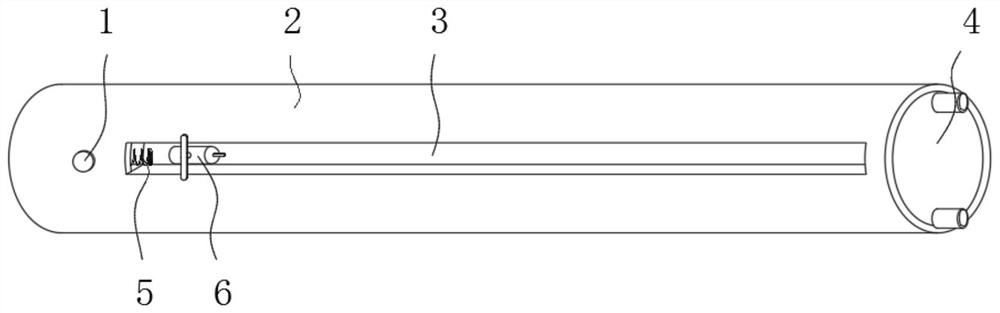

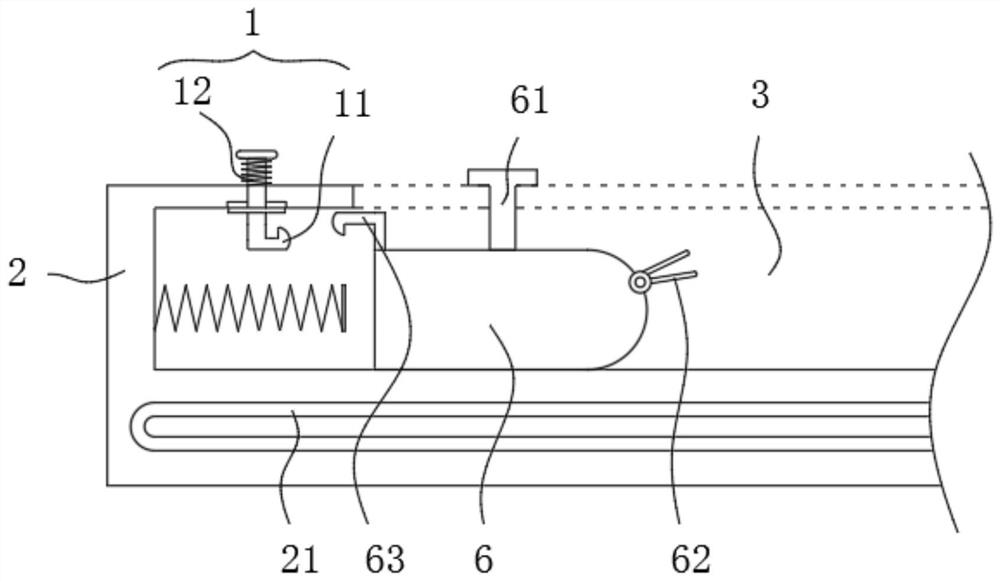

[0034]Such asFigure 1-Figure 3As shown, a wet splitting rod structure for a wet splitting and layering device of a sizing machine includes a wet splitting rod body 2:

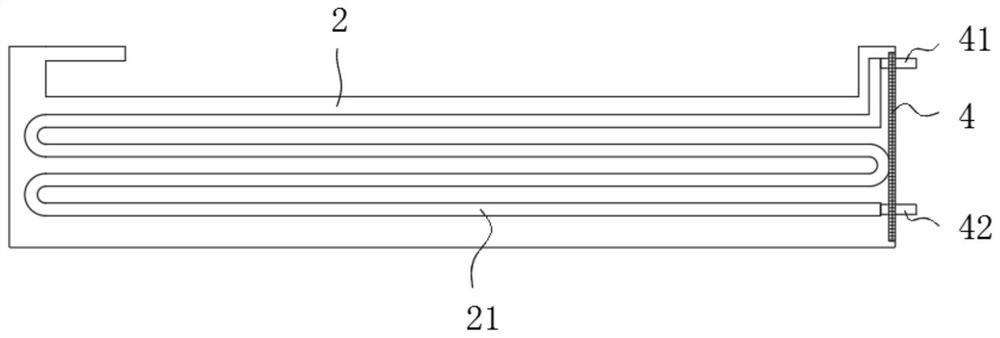

[0035]A multi-section U-shaped cooling pipe 21 is embedded in the wet splitting rod body 2, and two ends of the cooling pipe 21 are respectively provided with a water inlet pipe 41 and a water outlet pipe 42;

[0036]The wet splitting rod body 2 is provided with a slide groove 3, and the slide groove 3 is embedded with a pin 6 and a wire clamp 62 is provided on the pin 6;

[0037]A compression spring 5 is provided on the wet splitting rod body 2 and located at the end of the sliding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com