Static performance calibration device and method for high-temperature strain sensor

A calibration device and static performance technology, which is applied in the direction of measuring devices, electromagnetic measuring devices, instruments, etc., can solve the problems of high-temperature calibration devices with high requirements for substrates, difficult to control loading micro-strain accuracy, high temperature tolerance, etc., to achieve compact structure, Simple installation and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

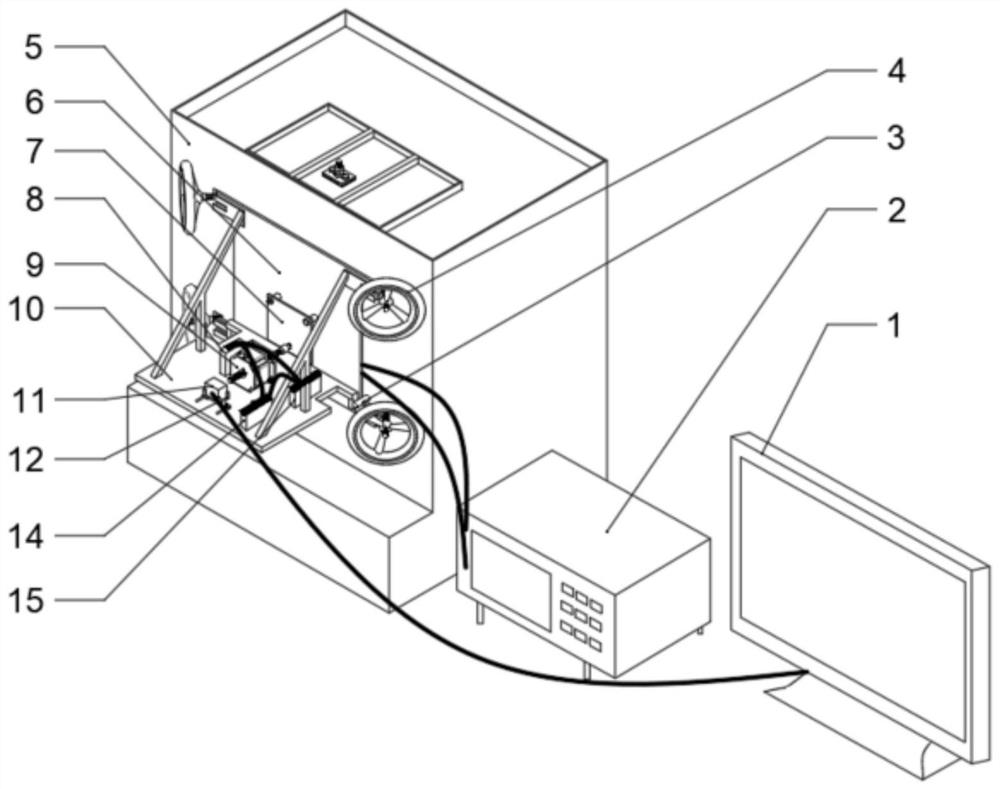

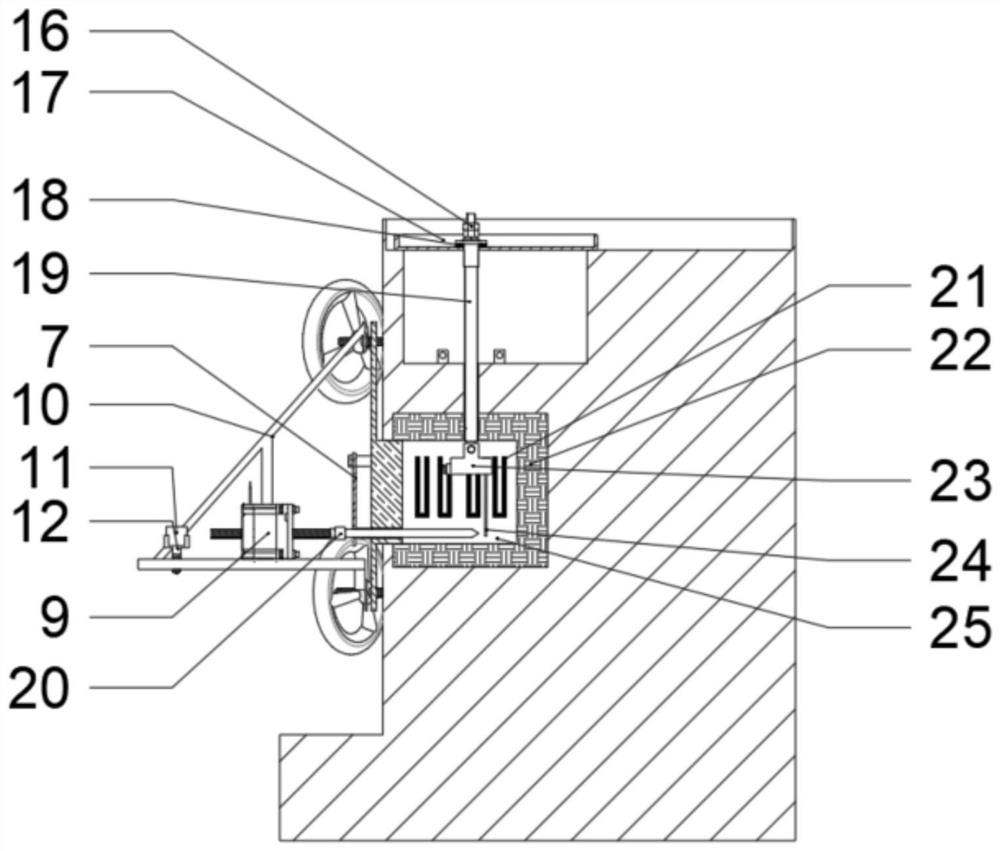

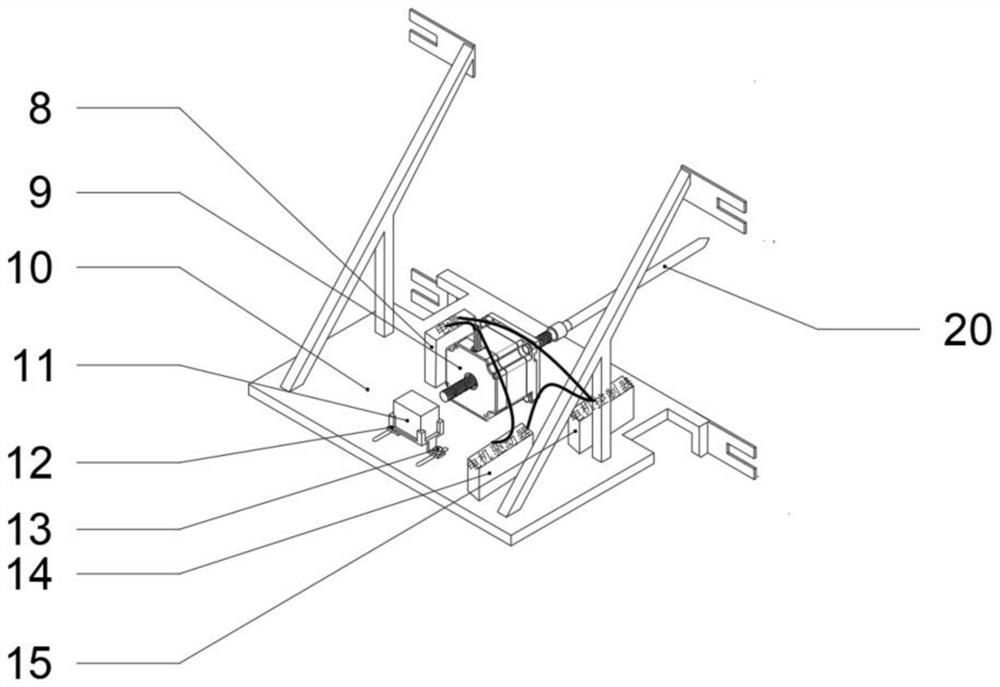

[0039] The high temperature strain sensor static performance calibration device of the present invention is as follows Figure 1-Figure 6 As shown in the figure, the maximum range of the laser displacement sensor is 10 mm, the display sensitivity is 0.5 μm, and the accuracy is 0.08% to 0.1%. The data is displayed and collected in the visualization window of Labview programming. The screw diameter of the linear stepper motor is 9.525mm, the thread lead is 5.08mm, the step angle of the motor is 1.8°, and the whole step length is 0.0254mm / step.

[0040] The present invention is a static performance calibration device for high-temperature strain sensors. The device is composed of a high-temperature furnace and a loading measurement system, wherein the high-temperature furnace is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com