Modeling simulation method of condenser ultrasonic cleaner

A simulation method, ultrasonic technology, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve problems such as labor and time consumption, high cost, and immature condenser descaling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0035] The modeling and simulation method of the condenser ultrasonic descaling device of the present embodiment comprises the following steps:

[0036] Step 1: Obtain the model, structural drawing and corresponding parameters of the condenser that needs ultrasonic descaling.

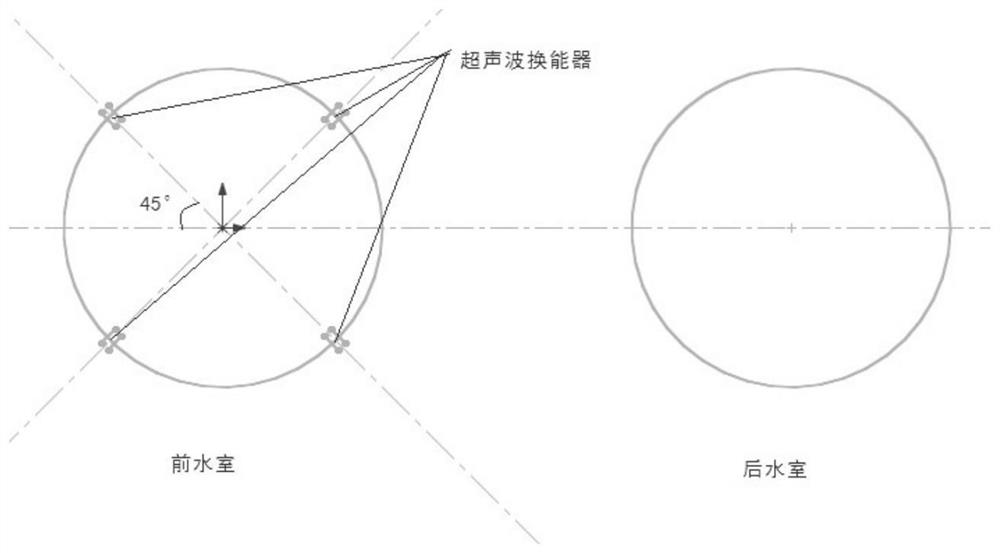

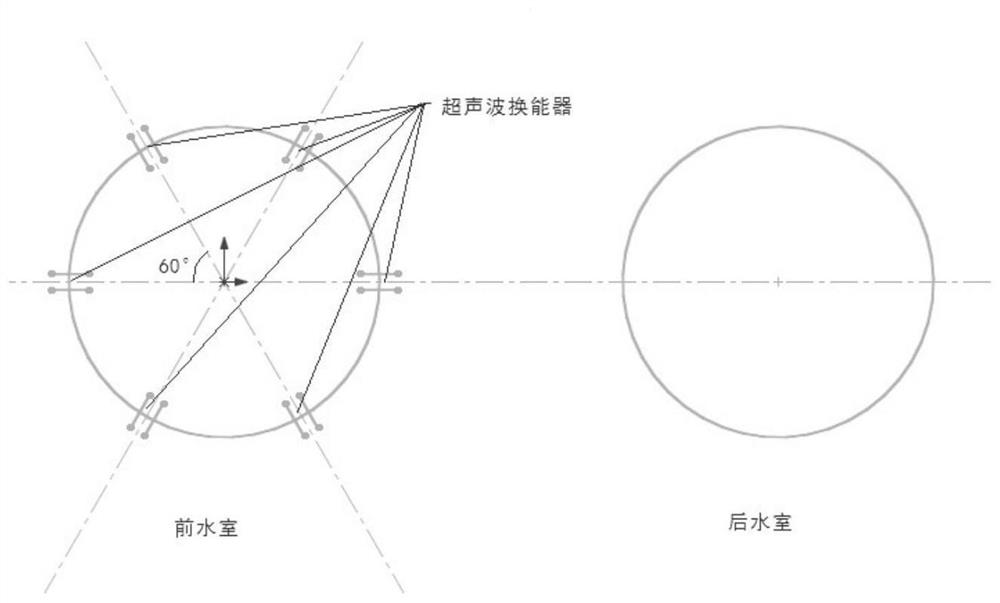

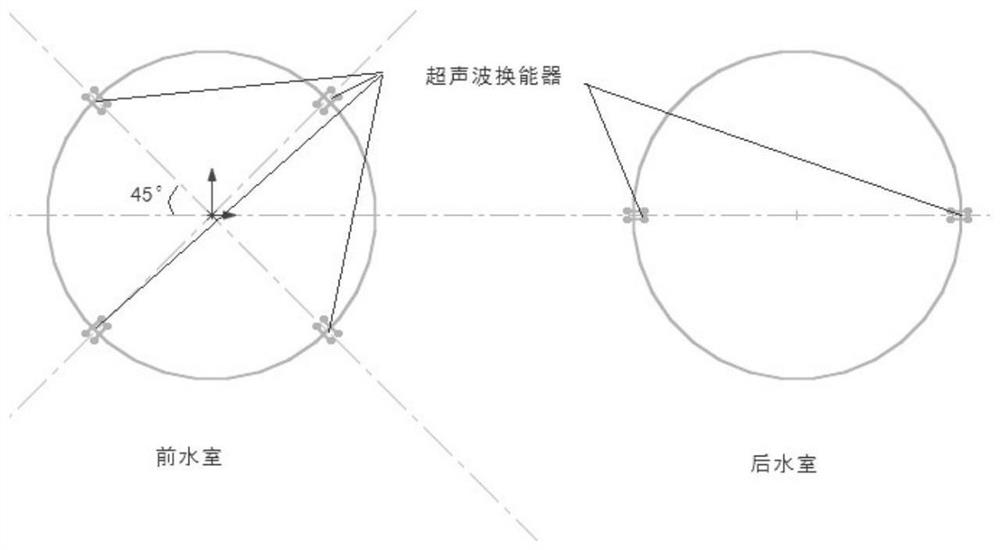

[0037] Step 2: Simplify the structure of the condenser according to the research focus, and keep the key research parts, that is, in this embodiment, in order to study the influence of ultrasonic waves on the flow field in the cooling pipe, the structure of other components is simplified, and only the front water chamber, The rear water chamber and the condensation pipes of the schematic arrangement structure.

[0038] Step 3: Construct a series of parametric structural models in the 3D model drawing software. In the parametric structural model of this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com