Method and system for evaluating service life of excavator working device

A working device and life evaluation technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as inability to effectively evaluate the service life of excavator arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

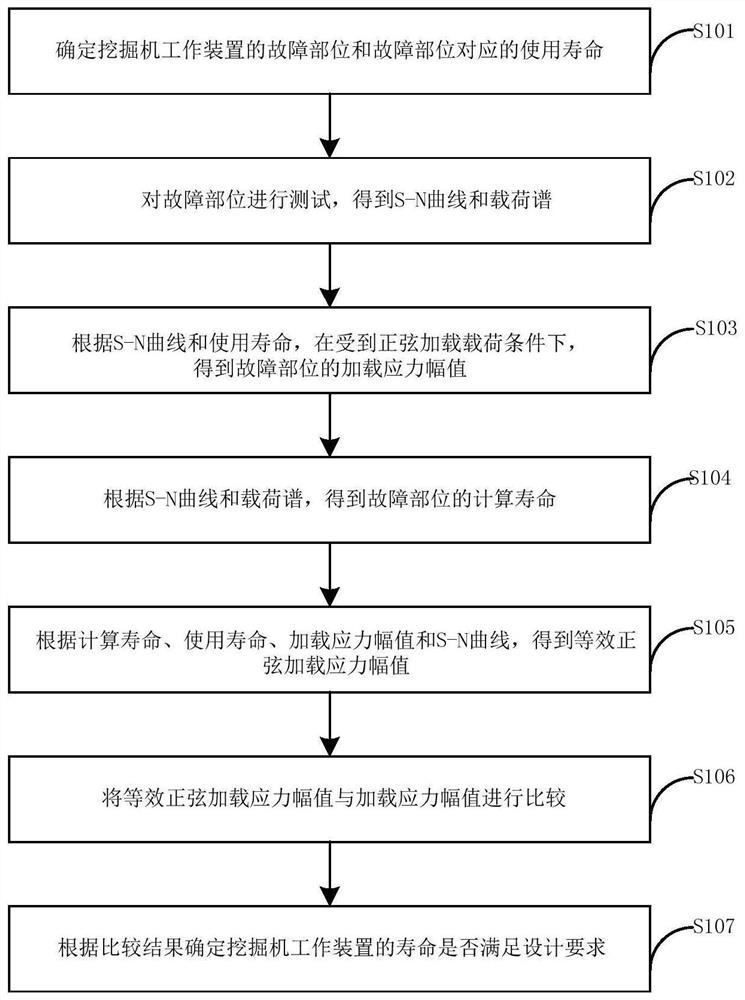

[0060] figure 1 It is a flow chart of the life assessment method for the working device of the excavator provided in Embodiment 1 of the present invention.

[0061] refer to figure 1 , the method includes the following steps:

[0062] Step S101, determining the faulty part of the working device of the excavator and the service life corresponding to the faulty part;

[0063] Specifically, the working equipment of the excavator includes but is not limited to the boom. The fault location of the boom is usually located at the position of the weld. The fault location of the boom includes at least: The butt welds between the fork bent plate and the front top plate, the butt welds between the middle top plate of the boom and the rear top plate, the welds between the outer plate of the front fork of the boom and the tail of the side plate, and the fillet welds between the bent plate and the side plate of the boom front fork. Among them, the faulty parts of the boom and the service li...

Embodiment 2

[0098] Figure 5 It is a schematic diagram of the life evaluation system of the working device of the excavator provided by the second embodiment of the present invention.

[0099] refer to Figure 5 , the system consists of:

[0100] The fault location determining unit 1 is used to determine the fault location of the working device of the excavator and the service life corresponding to the fault location;

[0101] The test unit 2 is used to test the fault location to obtain the S-N curve and load spectrum;

[0102] The loading stress amplitude acquisition unit 3 is used to obtain the loading stress amplitude of the fault part under the sinusoidal loading condition according to the S-N curve and the service life;

[0103] The calculated life acquisition unit 4 is used to obtain the calculated life of the fault part according to the S-N curve and the load spectrum;

[0104] The stress amplitude acquisition unit 5 is used to obtain the equivalent sinusoidal loading stress am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com