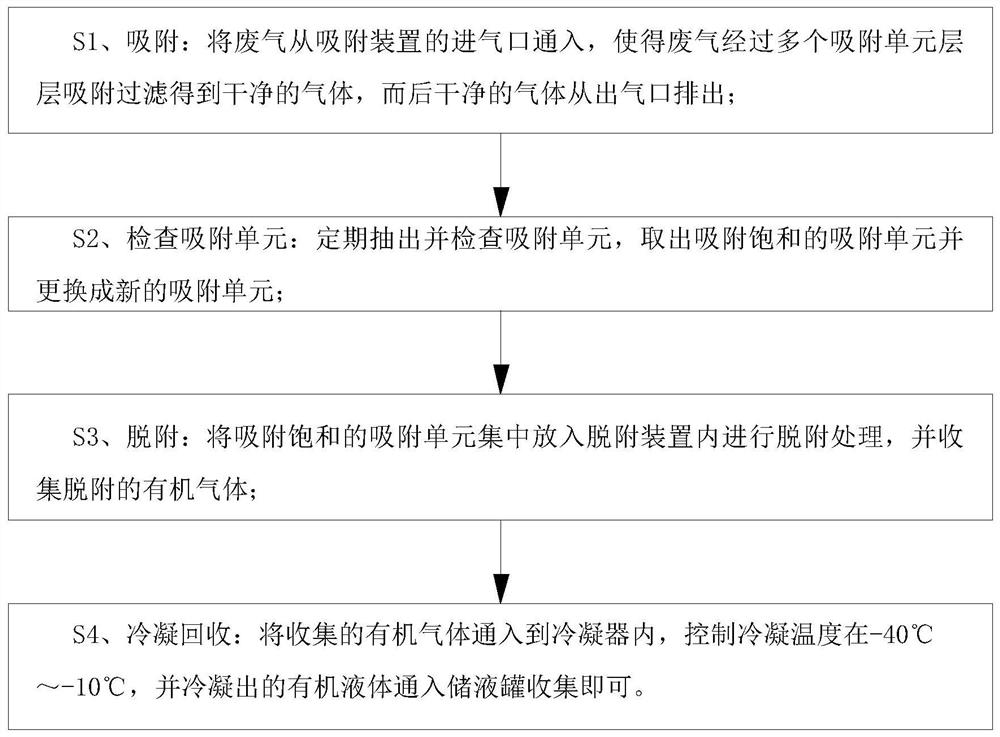

Activated carbon adsorption process

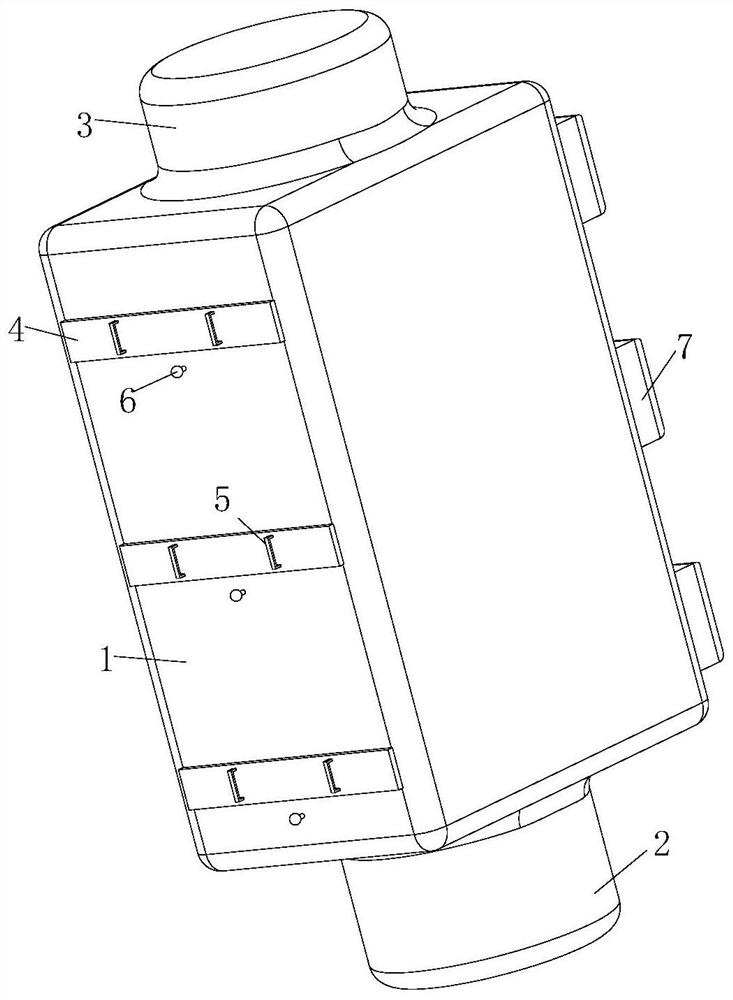

An activated carbon adsorption and process technology, applied in the field of activated carbon, can solve the problems of deformation, difficult replacement and explosion of adsorption equipment, reduce the probability of deformation or explosion, facilitate discovery and replacement, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

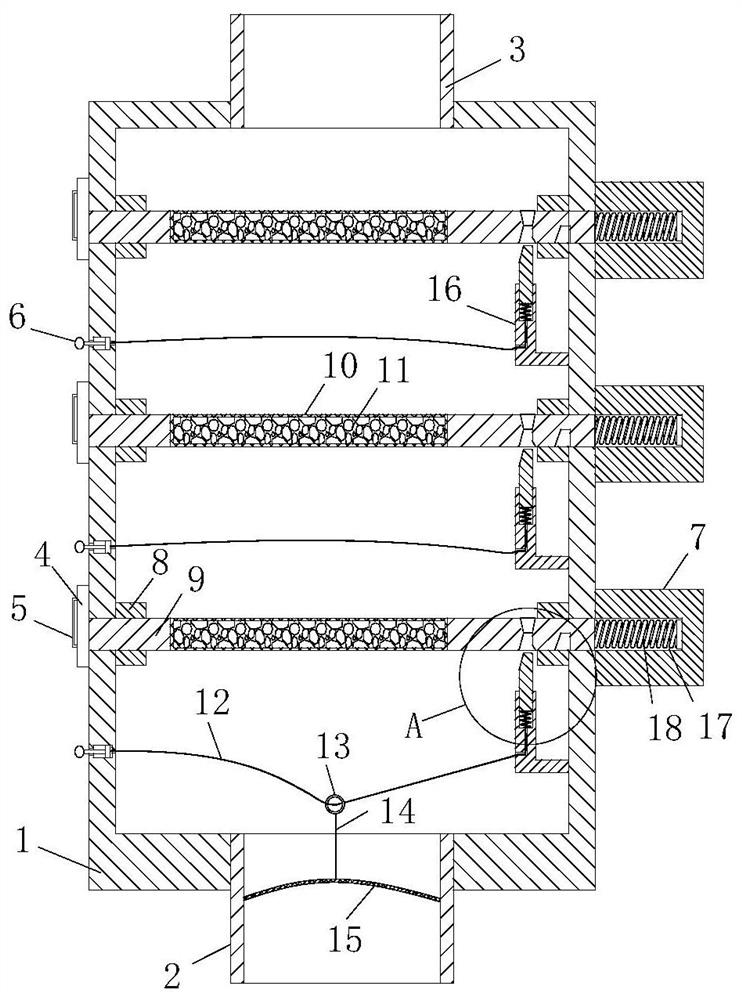

[0037] As an embodiment of the present invention, an L-shaped support plate 16 is provided under the other end of the insertion plate 9, the right end of the support plate 16 is fixed on the inner wall of the adsorption box 1, and the left end of the support plate 16 is vertically suspended. ; The left end of the support plate 16 is provided with a vertically arranged sinking groove 20, an inserting block 22 is arranged in the sinking groove 20, and a second spring 21 is arranged between the inserting block 22 and the bottom of the sinking groove 20; The second slot 24 corresponding to the size and position of the plug-in block 22 is arranged on the plug-in plate 9, and the right side lower end of the second slot 24 is provided with a circular arc chamfer 25, and the upper end of the plug-in block 22 is at the initial can be inserted into the second slot 24, and the upper end of the insert block 22 can break away from the second slot 24 along the arc chamfer 25 when the inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com