Method for detecting measurement stability of tester tables

A technology for testing and testing machines, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems of relatively large difference in oxide thickness, deviation of metal layer thickness, and difference in measurement results. Larger problems, to achieve the effect of easy observation and judgment, simple and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

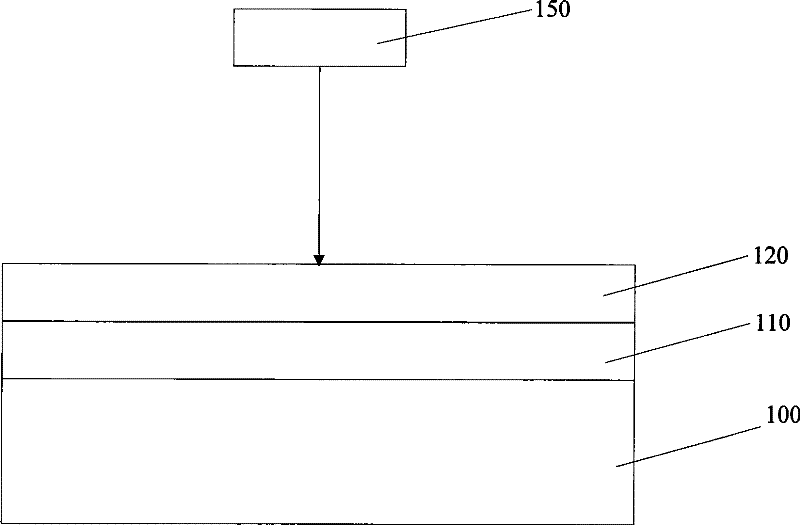

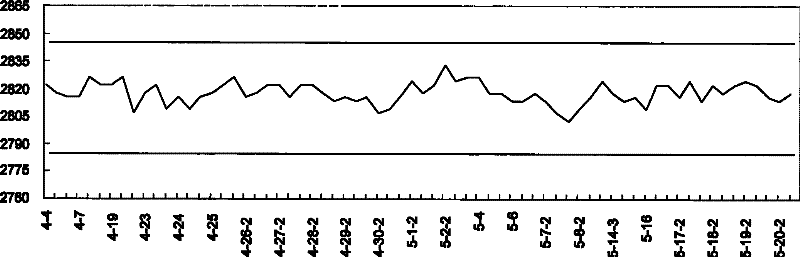

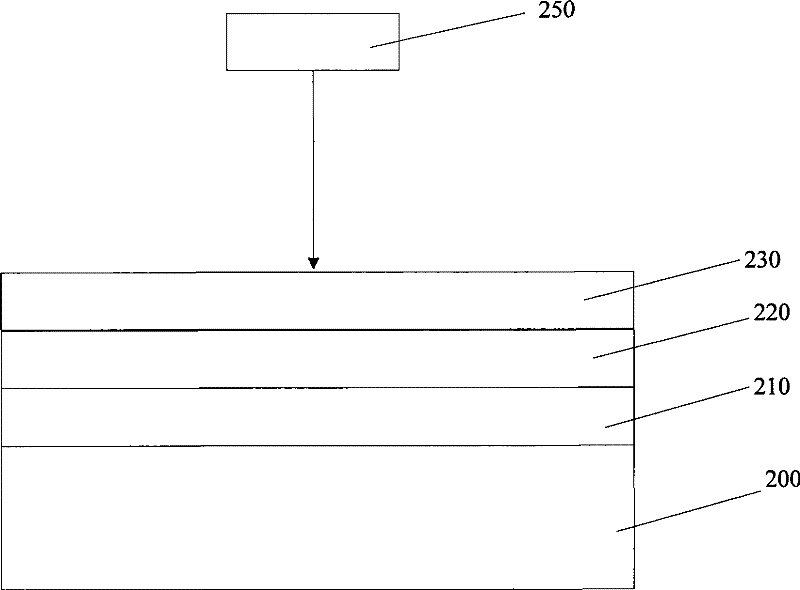

[0028] Please refer to image 3 , image 3 Shown is a schematic diagram of a method for detecting and testing a testing machine in a preferred embodiment of the present invention. The method for detecting and measuring the stability of the testing machine proposed by the present invention is aimed at testing devices such as microsecond ultrasonic laser sonar. First, a control chip is provided as a test wafer, and an oxide layer is formed on the semiconductor substrate 200 of the control chip. 210, the composition of the oxide layer 210 is SO 2 The oxide layer 210 may have a thickness of 1000 angstroms to 4000 angstroms. The purpose of forming the oxide layer 210 is to prevent the copper ions of the copper metal layer 220 electroplated from diffusing into the semiconductor substrate 200 during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com