Bottom cover manufacturing device suitable for inspection well

A technology for inspecting wells and bottom covers, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as high error rate, high manual labor intensity, and unsmooth process, and achieve accurate and controllable positions, good forming effects, flattened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

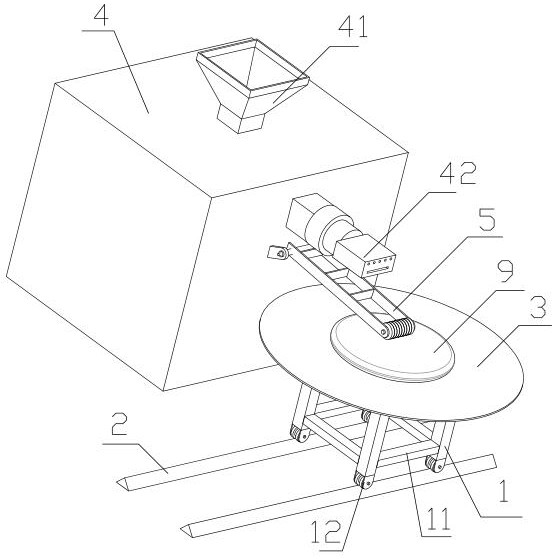

[0028] Example 1, such as figure 1 As shown, a bottom cover production equipment suitable for inspection wells includes a discharge device 4, and the discharge device 4 includes a material box 41 and an extrusion device 42. The material used to make the bottom cover, such as polyethylene, is placed In the head box 41 and extruded through the extrusion device 42 . As for the material box 41 and the extruding device 42, this part is the content of the prior art, and this solution does not make any changes to these two components, and will not repeat them here.

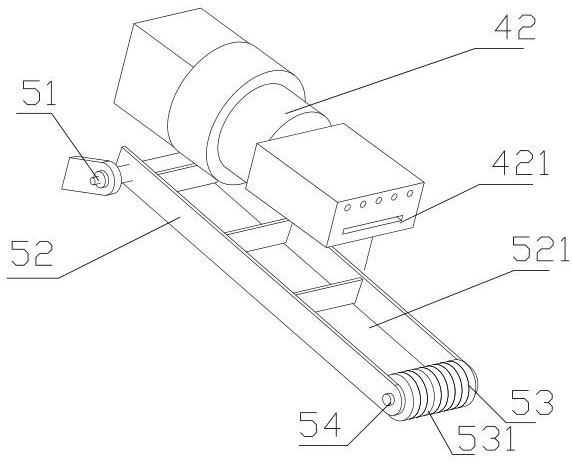

[0029] like figure 2 As shown, the extrusion device 42 includes an extrusion port 421. In this embodiment, the extrusion port 421 is a strip-shaped opening, and the material is in the shape of a flat strip when extruded. A shaping device 5 is installed below the extrusion device 42, and its main part is a connection frame 52, which is a frame-shaped design structure. The connection frame 52 has an avoidance space 521 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com