Bottle feeding device for full-automatic solid-liquid mixed food bottling machine

A solid-liquid mixing and food bottle technology, applied in bottling machines, synchronizing devices, packaging, etc., can solve the problems of high maintenance probability, accumulated errors, affecting normal production, etc., achieve precise rotation coordination, improve production efficiency, avoid The effect of stopping adjustment to correct the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technology will be further described below in conjunction with the accompanying drawings.

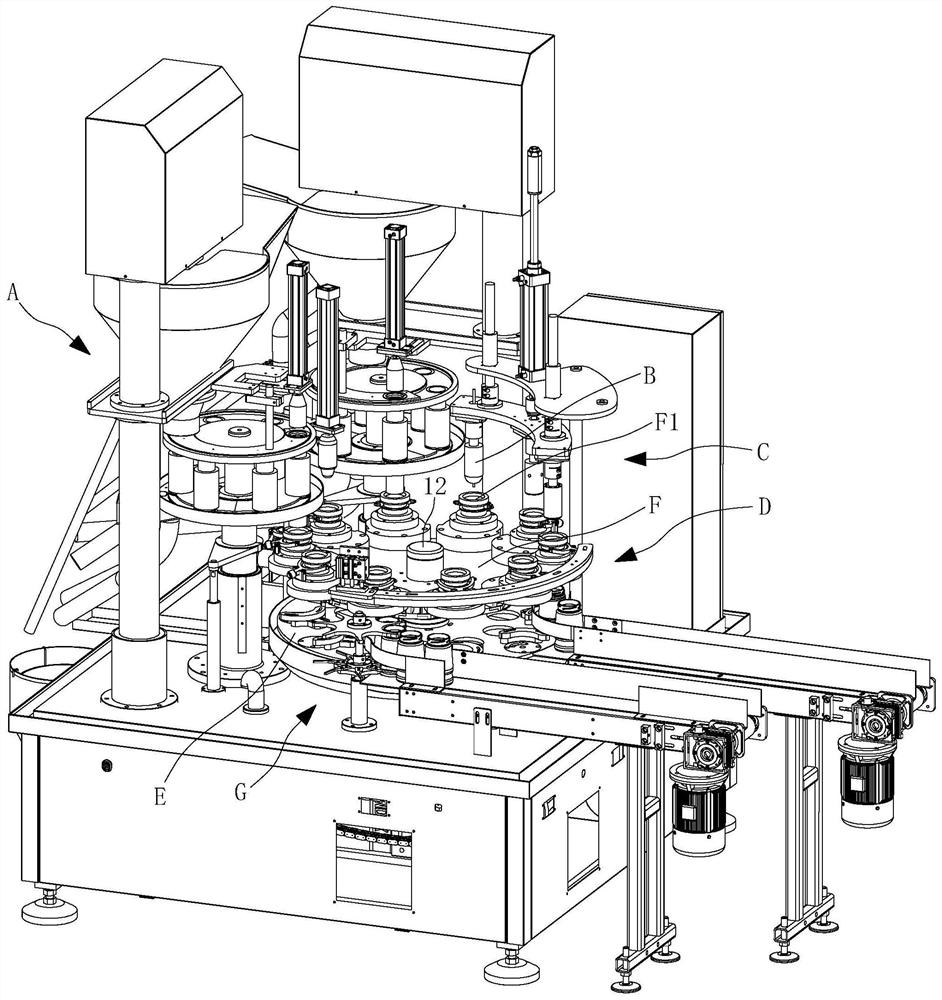

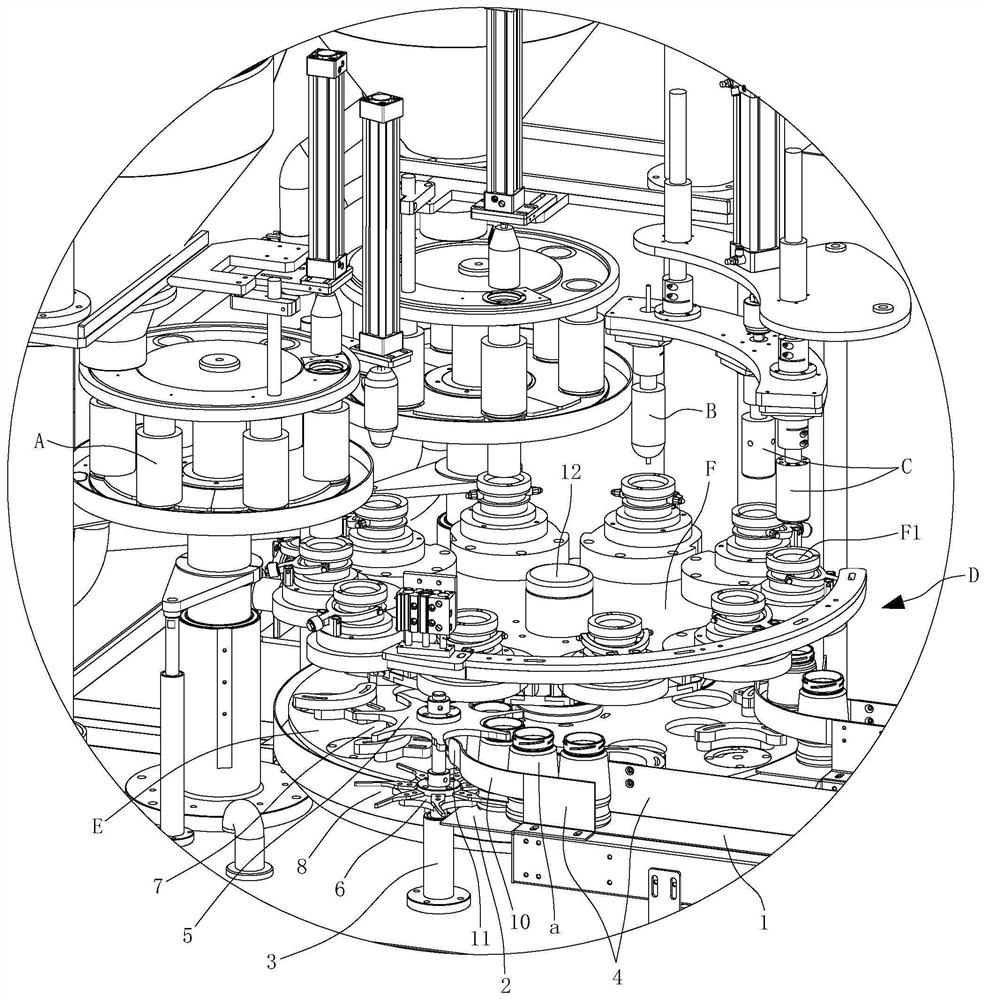

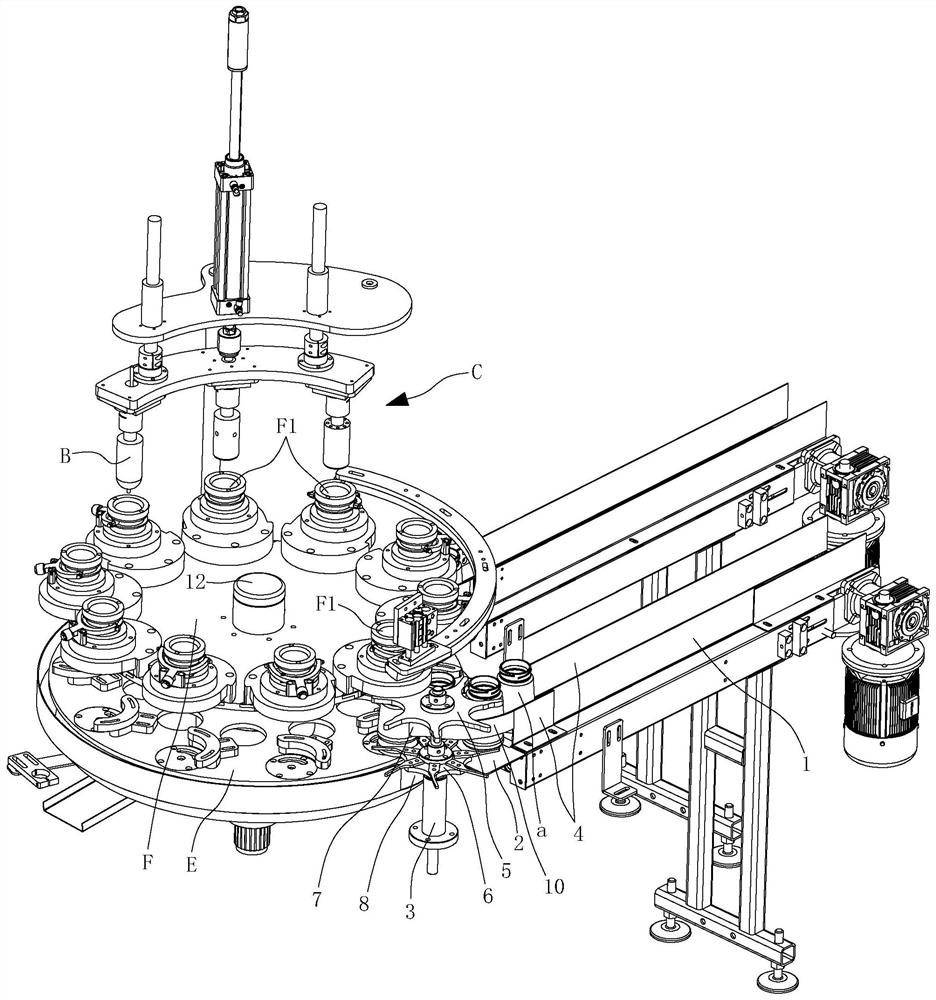

[0016] In the bottle feeding device of the fully automatic solid-liquid mixed food bottle filling machine of this embodiment, the bottle feeding device G is arranged next to the double turntable, and a weighing and feeding device A, a liquid injection head B, and a compactor are arranged in sequence along the circumferential direction of the double turntable. Device C and detachment device D, weighing and feeding device A is responsible for adding solid food, liquid injection head B is responsible for perfusing soaking liquid, compacting device C is responsible for compacting the solid food in the bottle, and detachment device D is responsible for compacting the solid food in the bottle. Bottles are sent off the carousel. In order to ensure that the bottles on the lower turntable E are fixed on the lower turntable E, a bottle pressing device F1 is specially set up on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com