Yarn breakage detection device, system and detection method

A broken yarn detection and broken yarn technology, which is applied in textiles and papermaking, looms, textiles, etc., to achieve the effects of good universality, low cost and reduced idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

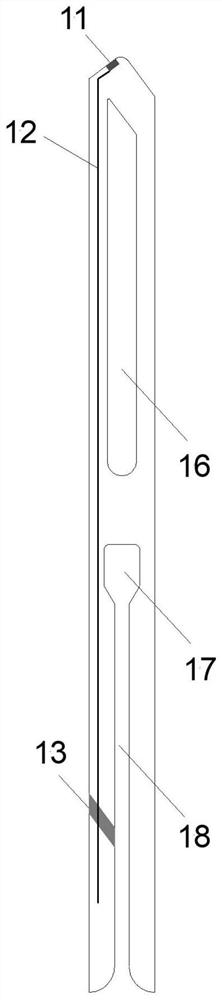

[0041] refer to figure 1 The menopause film shown in the present embodiment provides a kind of menopause film. The main body of the menopause film is made of metal materials. The yarn hole 17 communicates with the opening 18 , an LED lamp 11 is installed on the upper end of the beam-through hole 16 , and a wire 12 is arranged on one side of the beam-through hole 16 , and the LED lamp 11 is electrically connected with the wire 12 . An insulating region 13 is provided on one side of the opening 18 as a part of the negative electrode to form an electrical path.

[0042] In order to improve the conductivity, the conductive part of the wire 12 in this embodiment is made of copper wire.

[0043] The dropper provided in this embodiment is suitable for a loom with a safety stop unit, and after the loom stops, the voltage is switched by controlling the single-pole double-throw switch to re-supply power to the light-emitting element.

no. 2 example

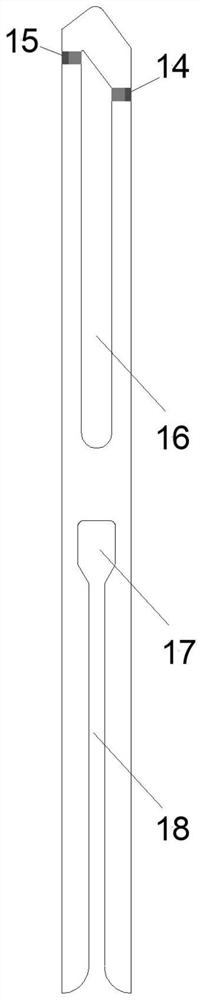

[0045] Such as figure 2 For the menacea shown in the above example, the menacea provided in this embodiment includes at least two light-emitting parts, and the LED lights 14, 15 and the menacea body are bonded together with a paint film of epoxy resin material, which is applicable to The loom of the unit lowers the power supply voltage by controlling the single-pole double-throw switch to re-supply the light-emitting element.

[0046] The thickness of the menopause provided by the present invention is set to 0.2-0.5mm, which depends on the diameter of the warp and the density of the warp. Generally speaking, the larger the diameter of the warp and the higher the density, the thinner the warp should be set to reduce menopause. The friction between the sheets and between the warp yarns and the drop sheets due to mutual movement reduces static electricity.

no. 3 example

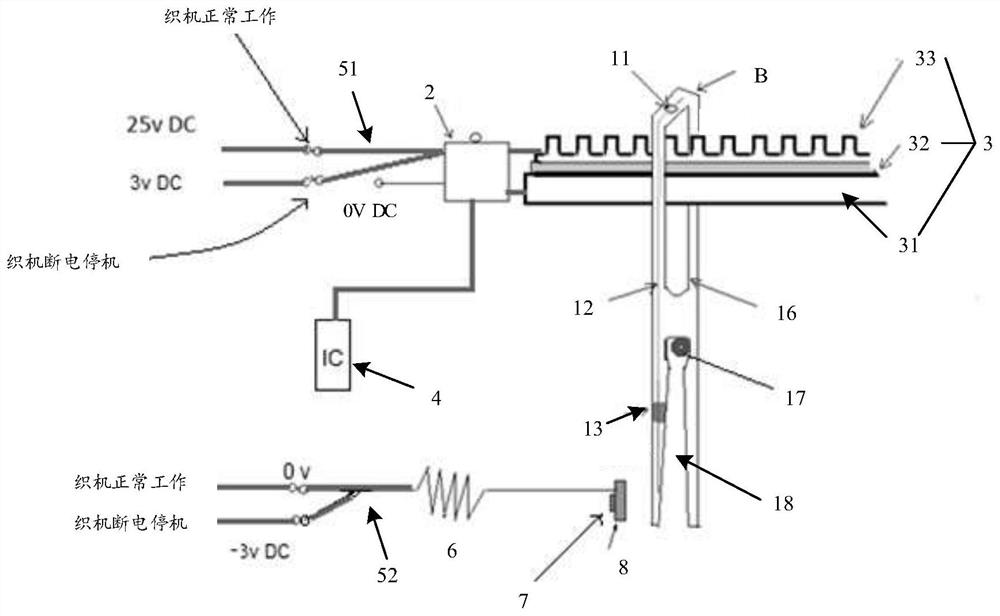

[0048] Such as image 3As shown, the present embodiment provides a broken yarn detection circuit, wherein the warp dropper provided by the first embodiment is used, and the loom equipped with a safety shutdown unit can automatically act as a light on the dropout wire without affecting the shutdown. The device provides a stable working voltage.

[0049] The control circuit includes a broken yarn self-stop controller 2, a warp stop beam 3, a stop signal receiving device 4 and a warp stop film;

[0050] The warp stop beam 3 includes a conductive peripheral body 31 and a conductive internal body 33, an insulator 32 is connected between the conductive peripheral body 31 and the conductive internal body 33, and the conductive internal body 33 and the conductive peripheral body 31 are all connected to the broken yarn automatically. The stop controller 2 is electrically connected, and several warp stoppers are erected on the warp stop beam 3 through the beam hole 16;

[0051] The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com