Single-arm lifting ring and production process thereof

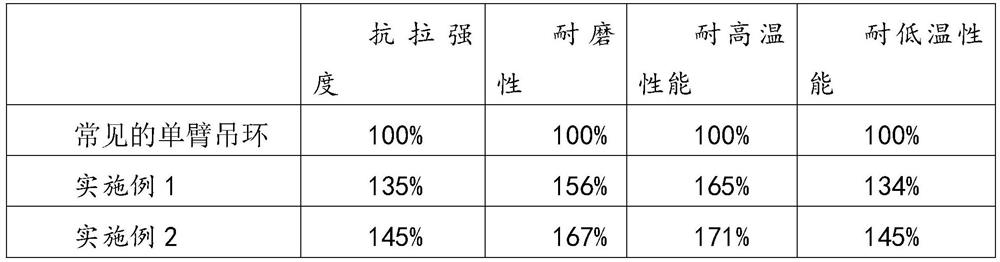

A production process and technology of lifting rings, applied in the field of single-arm lifting rings and its production technology, can solve the problems of unreasonable force on the lifting rings, coarse grains, stress concentration, etc., and achieve ideal comprehensive mechanical properties, uniform structure distribution, crystal crystal The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

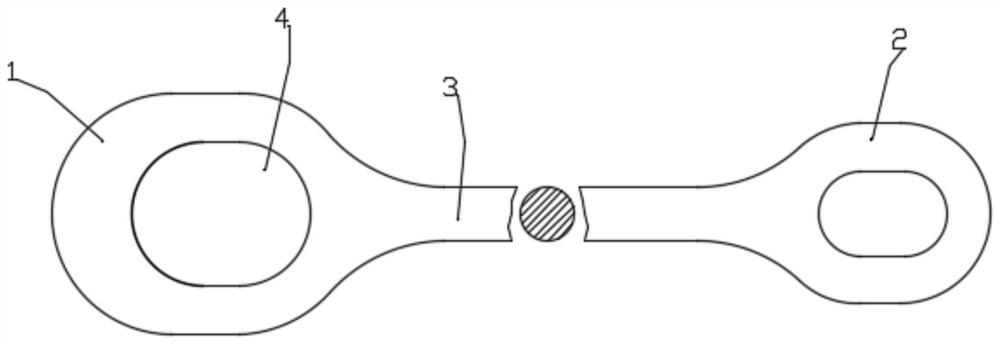

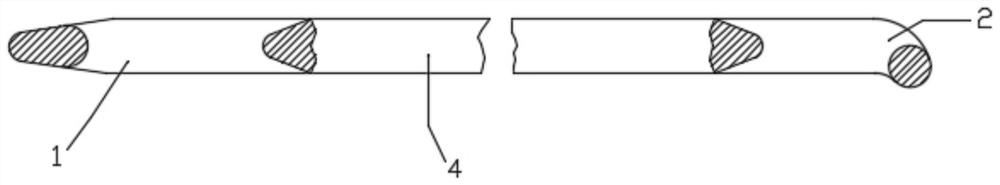

[0030] refer to figure 1 and figure 2 , a single-arm lifting ring, including a large ring 1 used to connect with the hook of the derrick and a small ring 2 connected with the elevator, and there is an integral body between the small ring 2 and the large ring 1 The formed middle straight rod 3, the small ring 2 and the large ring 1 have waist-shaped grooves 4 respectively, wherein the small ring 2 has a curvature relative to the horizontal plane, and the initial bending line of the small ring 2 is located at the center of the waist-shaped groove 4 , the inclination angle between the small ring 2 and the horizontal plane is 40°.

[0031] refer to figure 1 and figure 2 Compared with the traditional lifting ring, this single-arm lifting ring adopts the design of enlarged ring 1 and small ring 2 at both ends of the middle straight rod 3, and the appearance is simple and clear; when this single-arm lifting ring is used, the large ring 1 can be connected with the large The hook...

Embodiment 2

[0033] refer to figure 1 and figure 2 , the difference from Example 1 is that the small ring 2 has a curvature relative to the horizontal plane, and the initial bending line of the small ring 2 is located at the center of the waist-shaped groove 4, and the inclination angle between the small ring 2 and the horizontal plane is 60°. The force analysis shows that the force of the single-arm suspension ring is the most balanced at this time.

Embodiment 3

[0035] The difference from Example 1 is that the present invention also provides a production process for a single-arm suspension ring, which specifically includes the following steps:

[0036] S1. Material selection: manufacture high-grade high-quality alloy steel 20SiMn2MoVE;

[0037] S2. Forging: Forging the steel of S1, the forging ratio is controlled not less than 3:1, and the forging texture is ensured on the entire component during forging. The forging adopts the form of die forging and free forging. Forging to ensure the shape and size, the middle straight bar 3 adopts free forging;

[0038] S3, machining: the large ring 1 and the small ring 2 are machined by a machining center, and the middle straight rod 3 is processed by a numerical control machine tool;

[0039] S4. Quenching and tempering treatment: the heat treatment process of normalizing-high temperature tempering-quenching-tempering is used for modulation treatment.

[0040] Among them, the shape and positio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap