Oval partition plate nozzle modification method for increasing acoustic energy dissipation

A baffle and nozzle technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems affecting the normal progress of system tasks, unstable combustion in the combustion chamber, and pressure fluctuations in the combustion chamber, achieving easy processing, Simple structure, increase the effect of sound energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

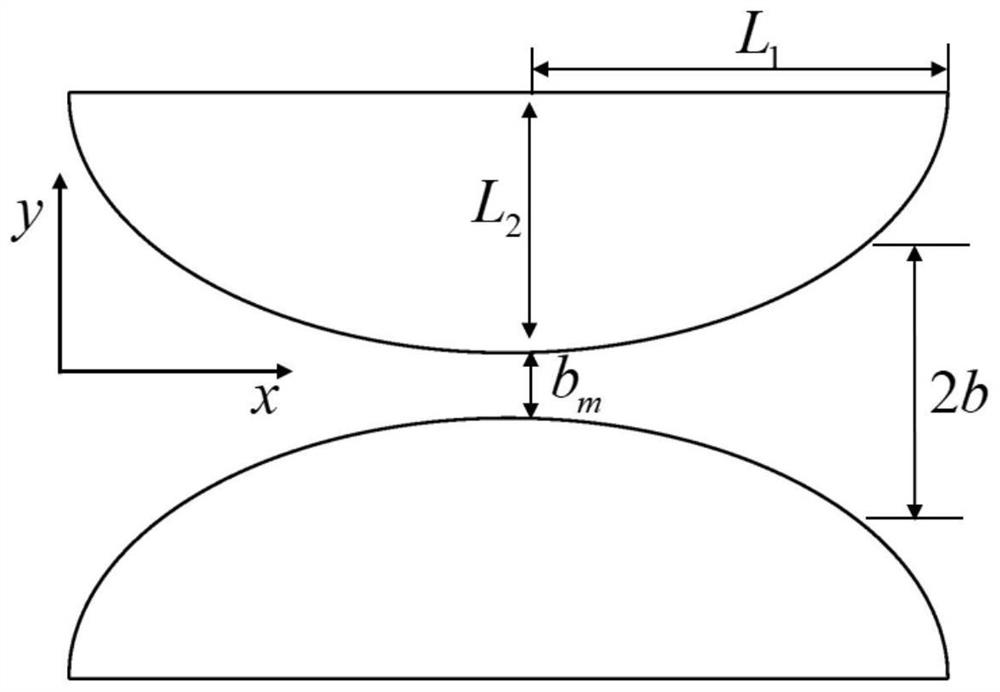

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings. In this embodiment, the sound energy dissipation is effectively increased by changing the eccentricity of the elliptical partition nozzle, and the specific implementation is described as follows:

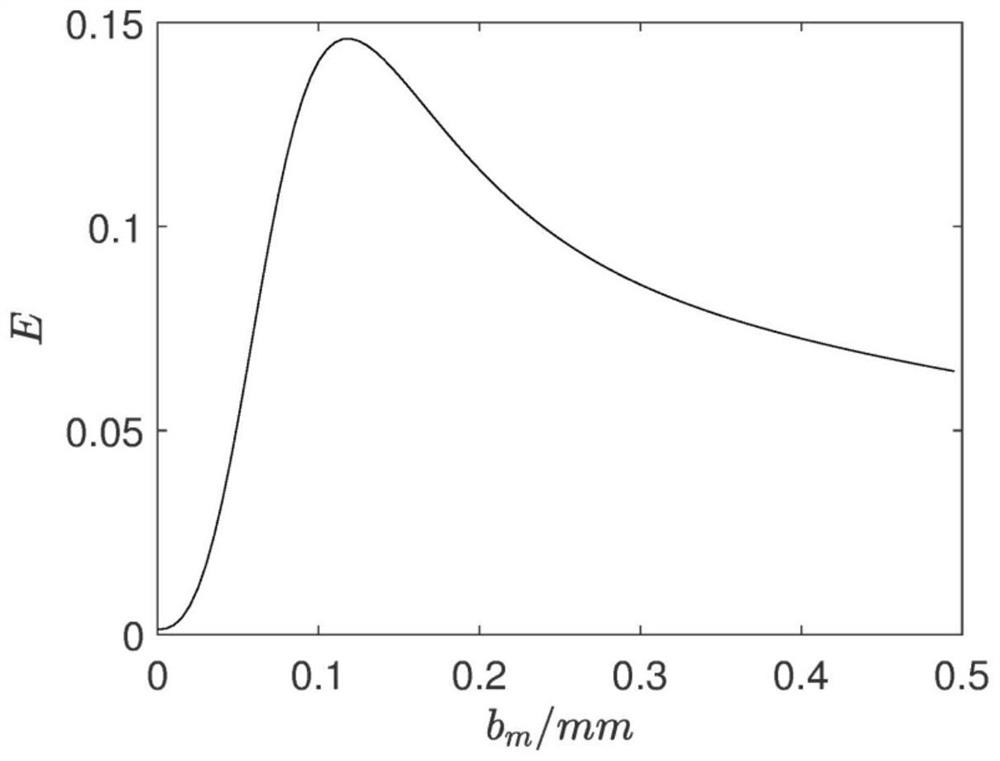

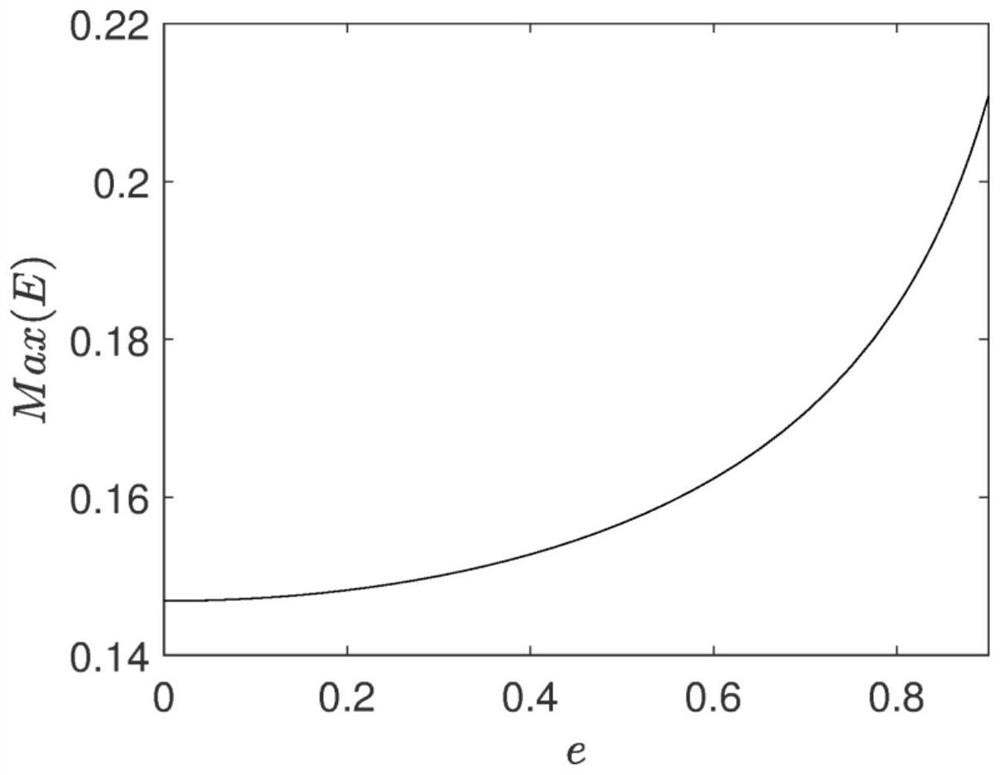

[0056] In this embodiment, under normal temperature and pressure, the operating frequency f is selected to be 1000 Hz, and the longitudinal semi-axis length of the separator nozzle is L 1 10mm, the range of eccentricity is 0~0.9, the minimum clearance b m The change range is 0-0.5mm. By calculating the wave equation, the law of the maximum sound energy dissipation changing with the eccentricity is obtained, as shown in the figure. image 3The working frequency is 1000Hz, the longitudinal semi-axis length of the diaphragm nozzle is 10mm, the variation range of the minimum gap is 0-0.5mm, and the law of the maximum sound energy dissipation with the eccentricity of the ellipse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com