Method and device for predicting service life of thin-film capacitor and computer equipment

A film capacitor and life prediction technology, which is applied in measuring devices, design optimization/simulation, instruments, etc., can solve the problems of reduced power control accuracy, changes in output characteristics of wind power converters, and no good prediction of film capacitor life. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Features and exemplary embodiments of various aspects of the invention will be described in detail below. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention.

[0034] Embodiments of the present invention provide a method, device, and computer equipment for life prediction of a thin film capacitor. By adopting the technical solutions in the embodiments of the present invention, the lifespan of the film capacitor can be accurately predicted in the design stage of the wind power converter, thereby providing theoretical guidance for the type selection and design of the film capacitor.

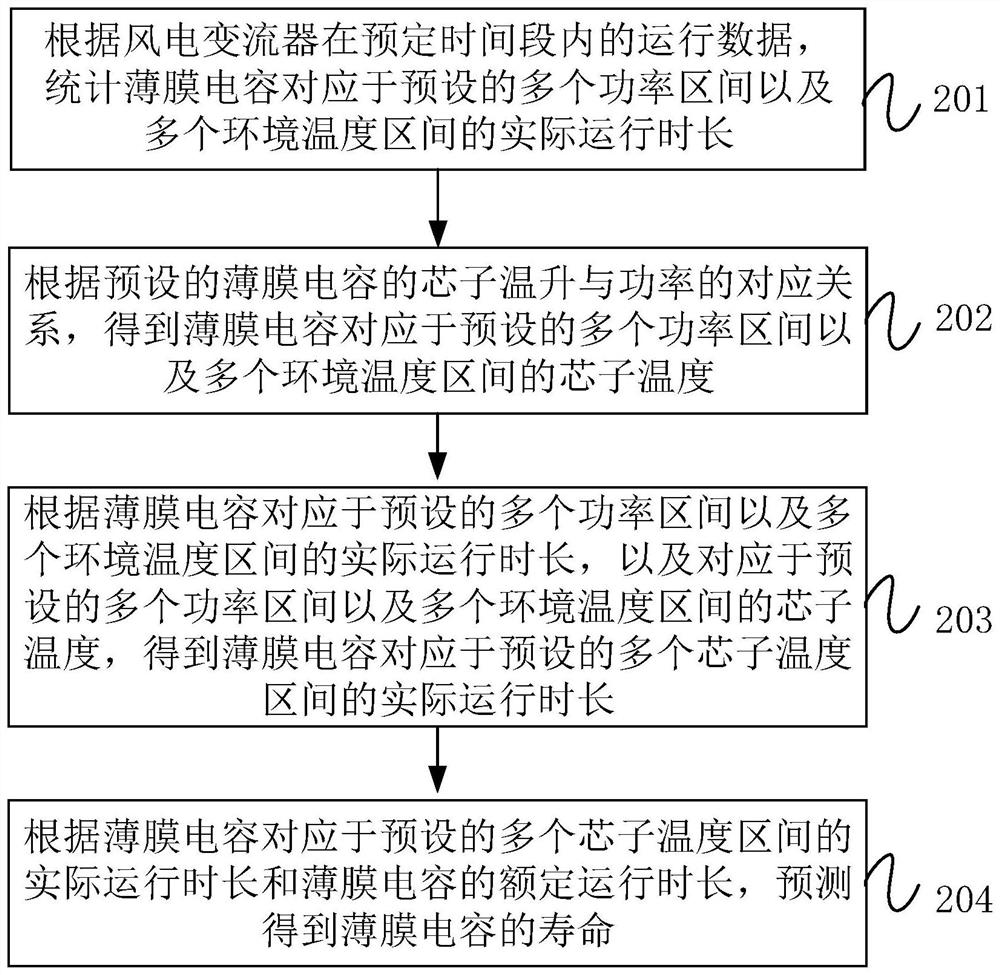

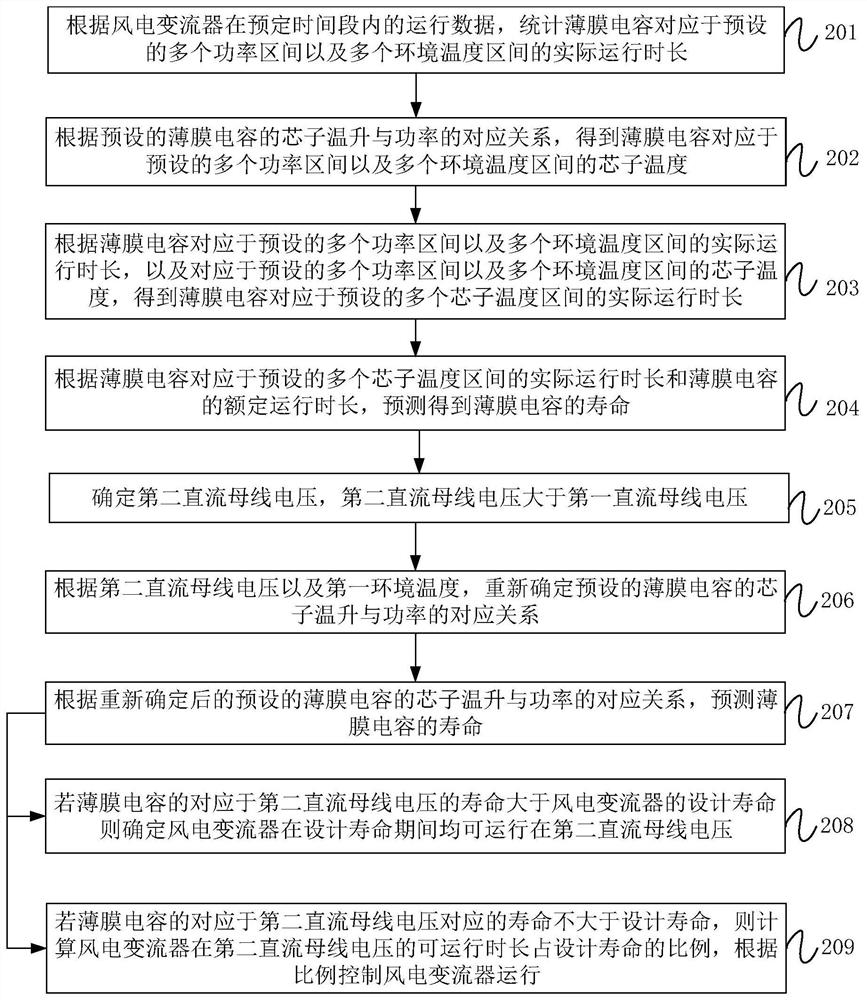

[0035] figure 2 It is a schematic flowchart of a method for predicting the lifetime of a film capacitor provided by an embodiment of the present invention. like figure 2 As shown, the life prediction method includes steps 201 to 204 .

[0036] In step 201 , according to the operation data o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap