High-voltage device coil assembly machining equipment

A technology for processing equipment and coils, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems such as low work efficiency, achieve stable welding, strong and sufficient welding, and reduce the defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

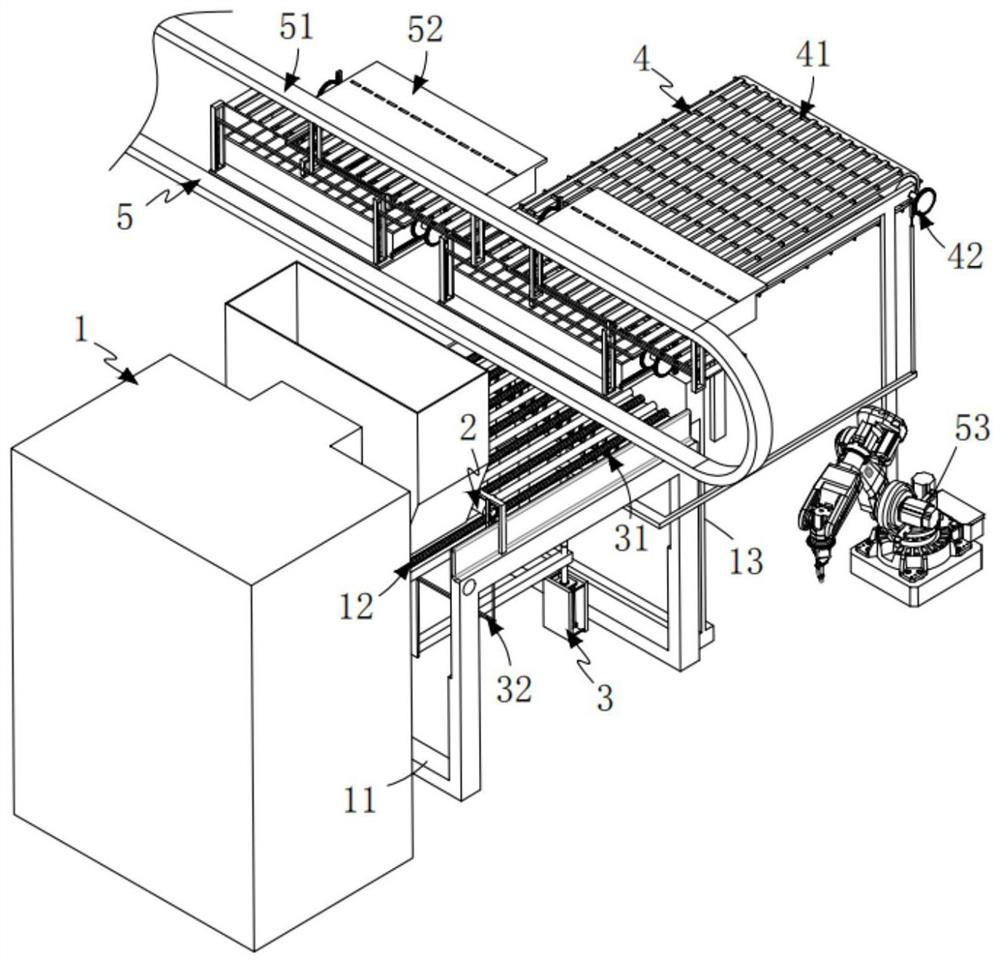

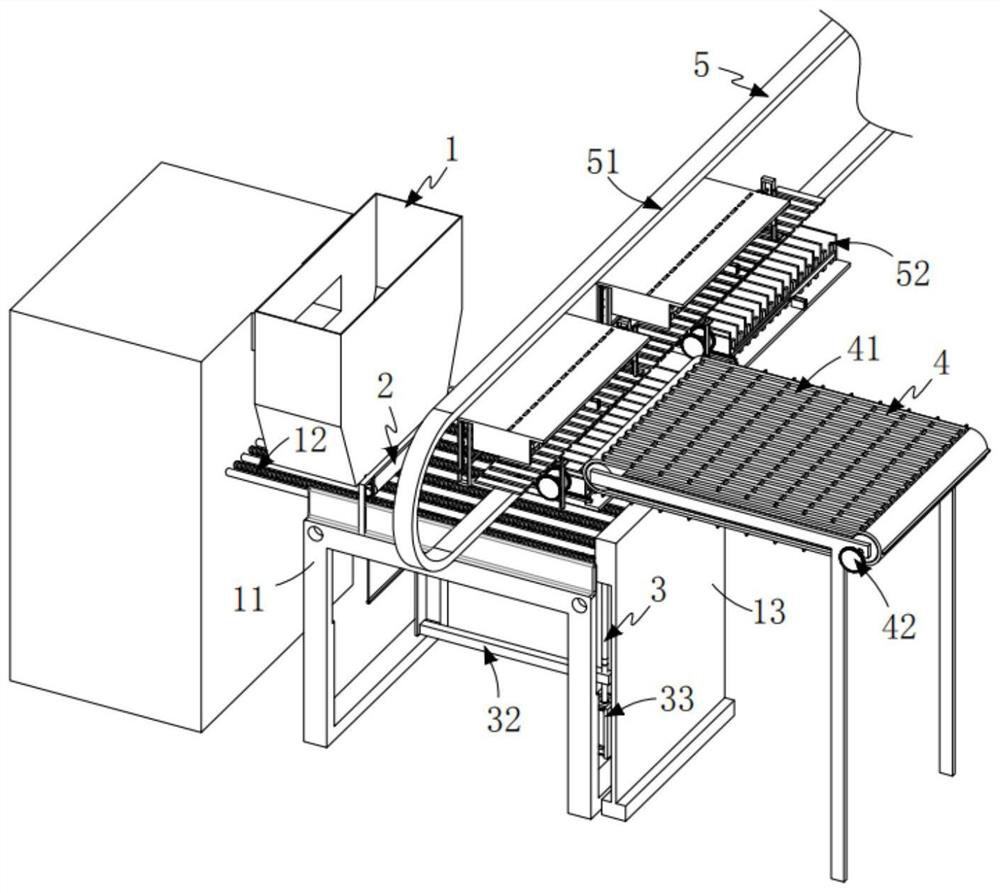

[0057] Such as figure 1 , figure 2 As shown, a high-voltage coil assembly processing equipment includes:

[0058] The laying mechanism 1 includes a frame 11, several groups of first transmission components 12 that are rotatably arranged on the frame 11 and extend along the length direction of the frame 11, and are arranged on the first The output end of the transmission assembly 12 and the seat plate 13 installed on the frame 11, the first transmission assembly 12 is driven by the first drive mechanism 14 for synchronous transmission;

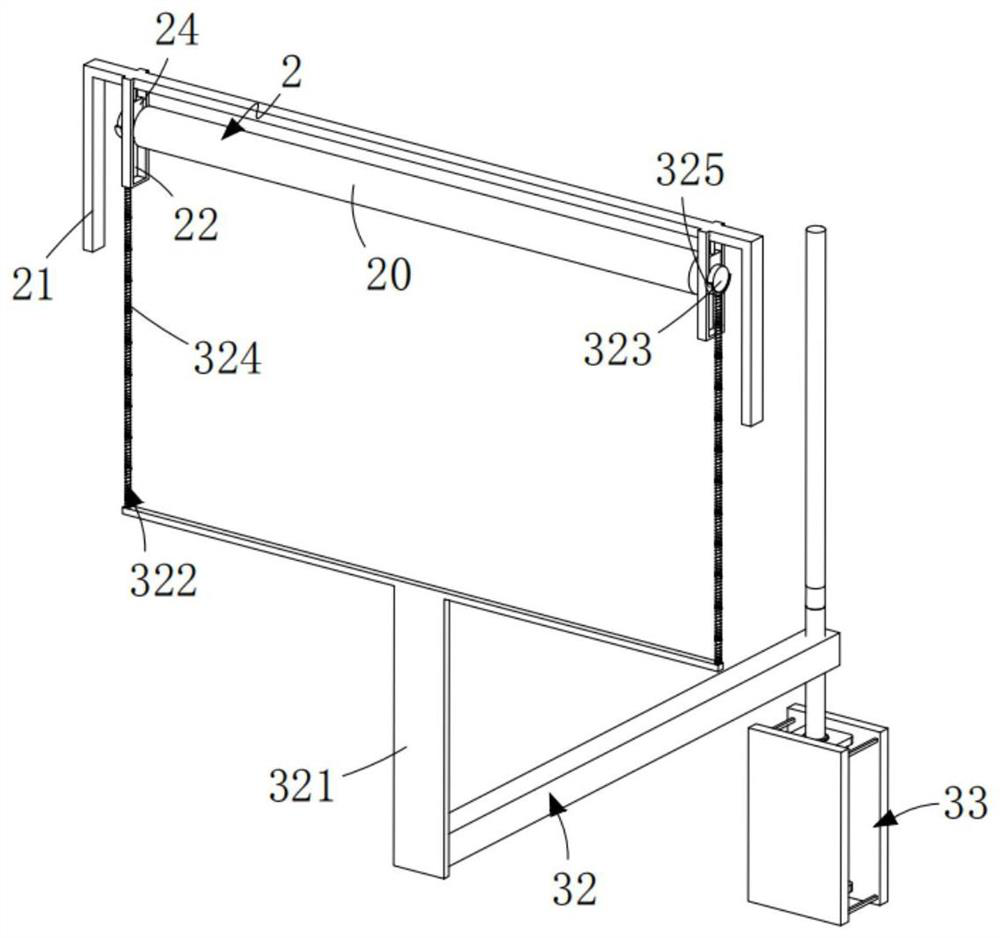

[0059] A height limiting mechanism 2, the height limiting mechanism 2 is installed on the frame 11 and arranged along the width direction of the frame 11, the roller shaft 20 of the height limiting mechanism 2 is driven to rotate by the second drive mechanism 25;

[0060] The lifting mechanism 3, the lifting mechanism 3 includes a clamping assembly 31 disposed at the output end of the first transmission assembly 12 and a second transmission ...

Embodiment 2

[0098] Such as Figure 11 to Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0099] further, such as Figure 12 As shown, the positioning assembly 52 includes a horizontal pushing assembly 521 and a vertical pressing assembly 524;

[0100] The horizontal push assembly 521 includes a flat push cylinder 522 arranged on the bottom frame 514 with the telescopic end facing the limit seat 515 and a push plate 523 arranged on the telescopic end of the flat push cylinder 522;

[0101] The vertical pressing assembly 524 includes a transmission rack a525 fixedly connected to the telescopic end of the horizontal push cylinder 522, a transmission gear a526 meshed with the transmission rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com