Calcium aluminate thermionic emission device and preparation method

An emission device and electron emission technology, which is applied in the manufacture of thermionic cathodes, solid thermionic cathodes of discharge tubes, circuits, etc., can solve the problems of low thermoelectric conversion efficiency of thermionic emission devices, etc. work, reducing the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

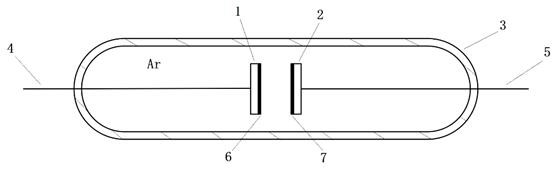

[0032] Such as figure 1 As shown, a thermionic emission device using calcium aluminate derivatives as thermal emitter materials includes:

[0033] A hot cathode electron emitter 1, a hot electron receiver 2, and a sealed quartz tube 3 for placing and fixing the hot cathode electron emitter 1 and the hot electron receiver 2. Both the hot cathode electron emitter 1 and the hot electron receiving stage 2 are based on molybdenum sheet, the hot cathode electron emitter 1 has a new material C12A7: C- / C coating 6, and the hot electron receiving electrode 2 has a rare earth oxide coating 7. The hot cathode electron emitter 1 is connected to the hot electron receiving stage 2 to lead out the hot cathode lead wire 4 and the receiving stage lead wire 5 respectively, and both the hot cathode lead wire 4 and the receiving stage lead wire 5 are made of molybdenum wire. The hot cathode electron emitter 1 and the hot electron receiver 2 are vertically fixed in the middle of the quartz tube ...

Embodiment 2

[0035] Such as figure 1 As shown, a thermionic emission device using calcium aluminate derivatives as thermal emitter materials includes:

[0036] A hot cathode electron emitter 1, a hot electron receiver 2, and a sealed quartz tube 3 for placing and fixing the hot cathode electron emitter 1 and the hot electron receiver 2. Both the hot cathode electron emitter 1 and the hot electron receiving stage 2 are based on molybdenum sheet, the hot cathode electron emitter 1 has a new material C12A7: C- / C coating 6, and the hot electron receiving electrode 2 has a rare earth oxide coating 7. The hot cathode electron emitter 1 is connected to the hot electron receiving stage 2 to lead out the hot cathode lead wire 4 and the receiving stage lead wire 5 respectively, and both the hot cathode lead wire 4 and the receiving stage lead wire 5 are made of molybdenum wire. The hot cathode electron emitter 1 and the hot electron receiver 2 are vertically fixed in the middle of the quartz tube ...

Embodiment 3

[0038] Such as figure 1 As shown, a thermionic emission device using calcium aluminate derivatives as thermal emitter materials includes:

[0039] A hot cathode electron emitter 1, a hot electron receiver 2, and a sealed quartz tube 3 for placing and fixing the hot cathode electron emitter 1 and the hot electron receiver 2. Both the hot cathode electron emitter 1 and the hot electron receiving stage 2 are based on molybdenum sheet, the hot cathode electron emitter 1 has a new material C12A7: C- / C coating 6, and the hot electron receiving electrode 2 has a rare earth oxide coating 7. The hot cathode electron emitter 1 is connected to the hot electron receiving stage 2 to lead out the hot cathode lead wire 4 and the receiving stage lead wire 5 respectively, and both the hot cathode lead wire 4 and the receiving stage lead wire 5 are made of molybdenum wire. The hot cathode electron emitter 1 and the hot electron receiver 2 are vertically fixed in the middle of the quartz tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com