Polarizing plate and display device

A polarizing plate, anti-glare technology, applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of inability to properly express anti-glare characteristics, irregularities, image distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1 to 3 and comparative preparation example 1 to 3

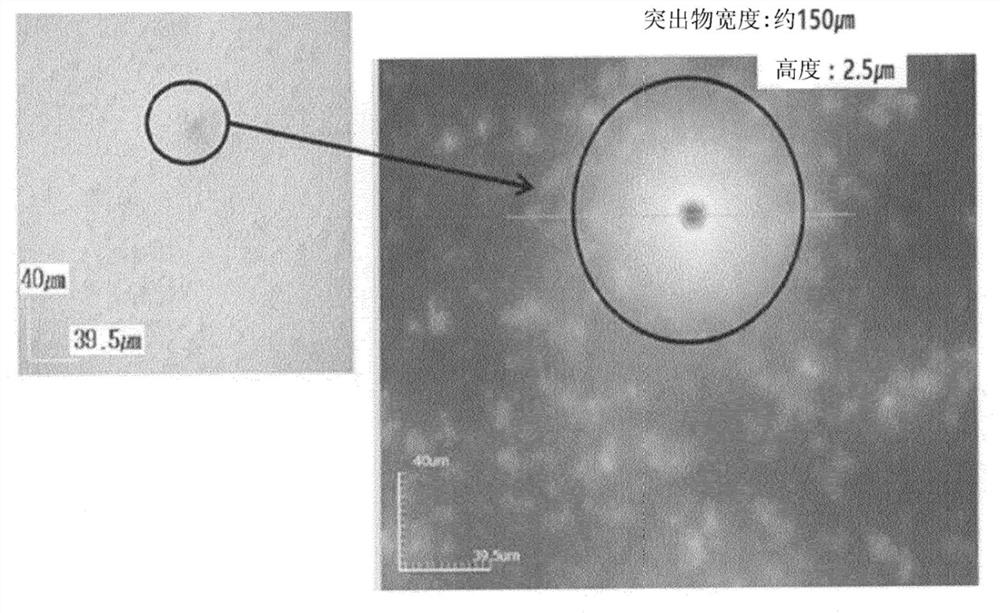

[0104] [Preparation Examples 1 to 3 and Comparative Preparation Examples 1 to 3: Preparation of Optical Laminates]

[0105] (1) Preparation of coating composition for forming anti-glare layer

[0106] The components shown in Table 1 below were mixed to prepare a coating composition for forming an antiglare layer.

[0107] (2) Preparation of optical laminate

[0108] Each of the above-prepared coating solutions for forming an anti-glare layer was coated on the polymer substrate described in Table 1 below by a #12mayer rod, and then dried at a temperature of 40°C for 2 minutes, followed by UV curing to form Anti-glare layer (coating thickness 4 μm). When performing UV curing, the UV lamp uses H bulbs, the curing reaction is carried out under a nitrogen atmosphere, and the amount of UV light irradiated during curing is 150mJ / cm 2 .

[0109] [Table 1]

[0110]

[0111] TMPTA: Trimethylolpropyl Triacrylate

[0112] PETA: pentaerythritol triacrylate

[0113] UA-306T: React...

Embodiment 1 to 3 and comparative example 1 to 3

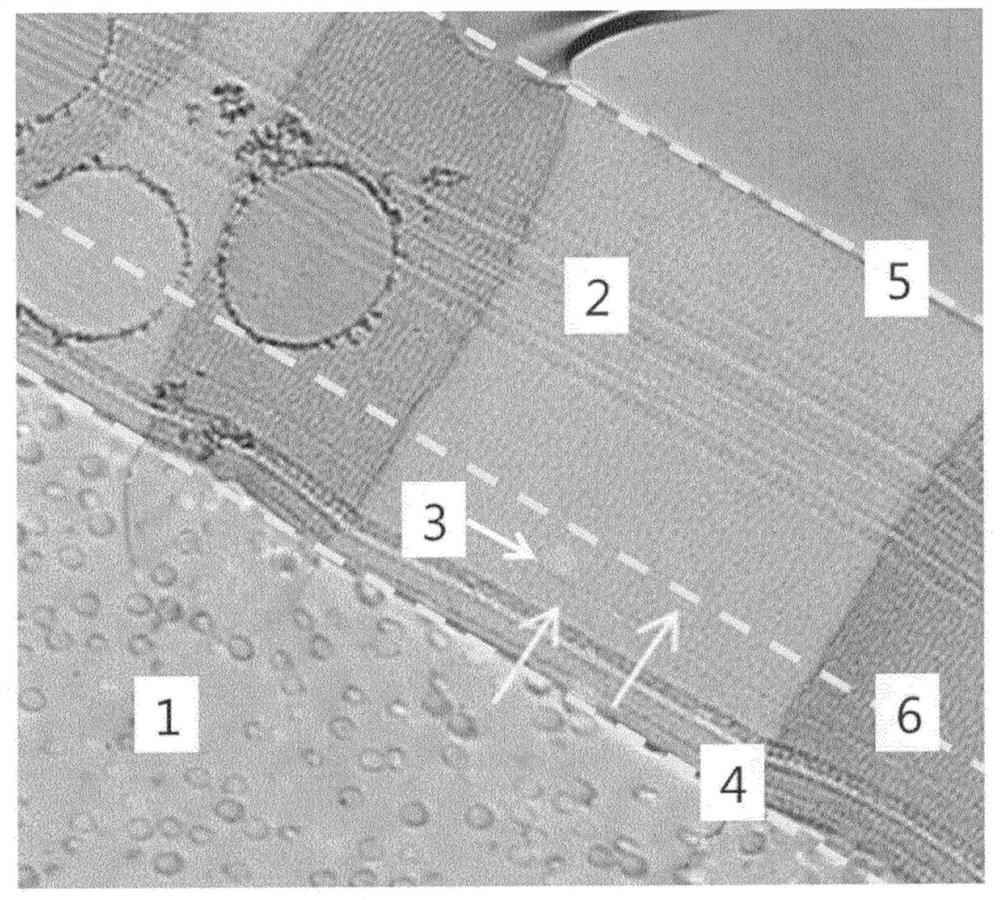

[0125] [Examples 1 to 3 and Comparative Examples 1 to 3: Preparation of polarizing plate]

[0126] A polyvinyl alcohol polarizer (thickness: 25 μm, manufacturer: LG Chem) was bonded to the polymer base side of the optical laminates prepared in each Preparation Example and Comparative Preparation Example using a UV adhesive.

[0127] Then, a 40 μm thick acrylate resin film (LG Chem product, 40 μm polymethylmethacrylate base) was bonded to the other surface of the polyvinyl alcohol polarizer using a UV adhesive to prepare a polarizing plate.

experiment example 1 to 5

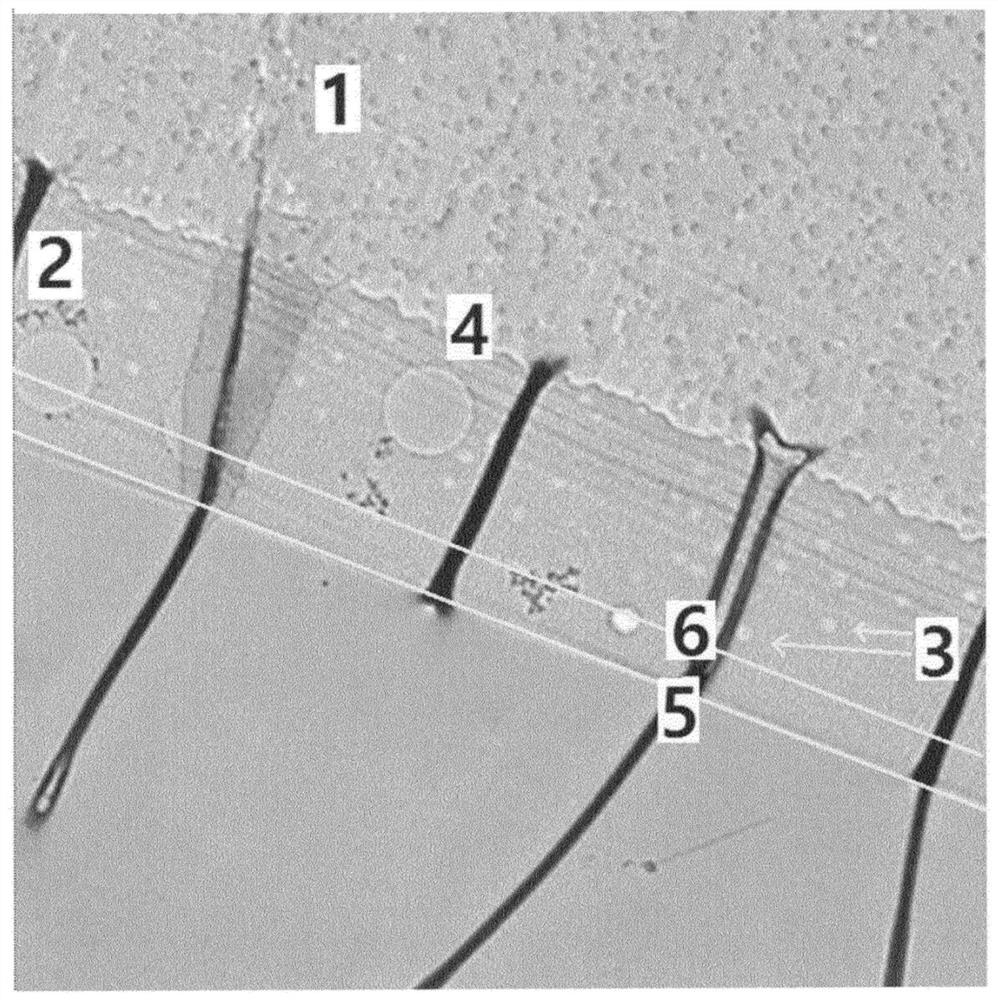

[0128] [Experimental Examples 1 to 5: Measurement of Physical Properties of Optical Laminates]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com