Lithium secondary battery

A lithium secondary battery and electrolyte technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of battery internal resistance increase and power failure, and achieve the effect of suppressing increase and preventing sudden power failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] 1. Embodiment 1: Lithium secondary battery preparation

[0094] Prepare the positive electrode active material, wherein the average particle size (D 50 ) is the first lithium cobalt oxide of 2.5 μm and the average particle size (D 50 ) is the second lithium cobalt oxide of 11 μm. In this case, the first lithium cobalt oxide and the second lithium cobalt oxide each containing aluminum at a concentration of 3,100 ppm were used.

[0095] Then, the positive electrode active material, carbon black as a conductive agent, and polyvinylidene fluoride (PVDF) as a binder were mixed in a weight ratio of 97.59:1.1:1.31, and then N-methyl-2- Pyrrolidone (NMP) to prepare positive electrode active material slurry (solid component content: 50% by weight). A 12 μm-thick aluminum (Al) thin film as a positive electrode collector was coated with the positive electrode active material slurry, dried, and then rolled to prepare a positive electrode.

[0096] Negative electrode active mate...

Embodiment 2

[0101] A lithium secondary battery was prepared in the same manner as in Example 1, except that a cathode active material in which the second lithium cobalt oxide and the second lithium cobalt oxide each contained aluminum at a concentration of 3,900 ppm was used.

experiment example 1

[0108] 1. Experimental Example 1: Continuous charging evaluation

[0109] Each of the coin-type lithium secondary batteries prepared in Examples 1 and 2 and Comparative Example 1 was activated at a constant current (CC) of 0.7C. After that, each lithium secondary battery was charged to 4.45V at a CC of 0.7C under constant current-constant voltage (CC-CV) conditions at 25°C, then cut off at a current of 0.05C, and discharged to 3.0V at a CC of 0.2C. V.

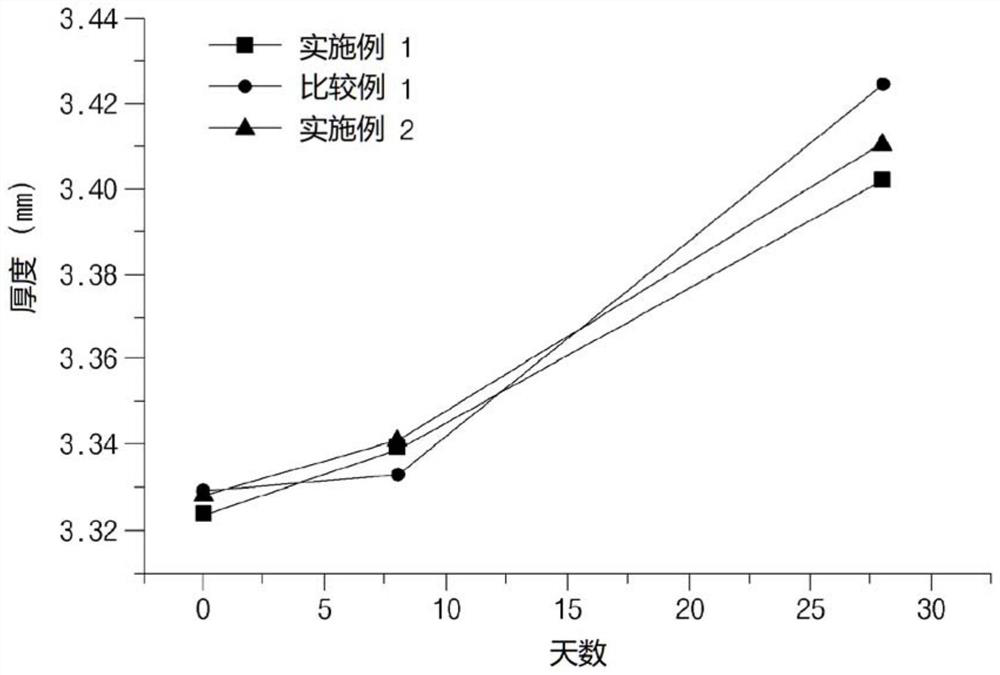

[0110] Next, each battery was continuously charged at a CC of 0.5C to 4.45V for 28 days under constant current-constant voltage (CC-CV) conditions at high temperature (45°C), and measured every 5 days using a 300gf flat plate thickness gauge once the thickness of each cell, the results are presented in figure 1 .

[0111] see figure 1 , in the case of continuous charging of each lithium secondary battery, it can be confirmed that since the expansion of the secondary battery of Comparative Example 1 exceeds that of the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com